Collaborative robots guide future factory changes! Compared with traditional industrial robots, it h

The future intelligent factory is created by the harmonious coexistence of people and machines. It requires robots to cooperate with humans and complete different tasks with humans. This includes not only the traditional tasks of "people can't do it, people don't want to do it, and people can't do it well", but also complex tasks that can reduce human labor intensity and improve the quality of human life

Market outlook 2022-09-18

In the field of intelligent manufacturing, palletizing robot has incomparable advantages over manual

It is difficult to move, place and store goods manually in the warehouse. If only relying on manual handling, it is impossible to achieve efficient storage. Therefore, the automation of warehouses is getting higher and higher, and palletizing robots are very common

Market outlook 2022-09-29

In the industrial field, the control technology of palletizing robot has these.

Compared with ordinary mechanical palletizer, the palletizing robot has the advantages of high efficiency, low failure rate and convenient maintenance, so it is widely used. The main task of palletizing robot control technology is to control the movement position, posture and trajectory, operation sequence and action time of industrial robot in the workspace. Now let's talk about the control technology of the stacking robot.

Market outlook 2022-09-27

Advantages and Disadvantages of China's Artificial Intelligence Industrial Palletizing Robot

With the development trend of scientific and technological artificial intelligence, in industry, cooperative palletizing robots will undertake more and more tasks in industrial production, leading to industrial robots competing for jobs with people. At this stage, industrial palletizing robots and people have their own advantages. The palletizing robot is warmly welcomed by companies and enterprises for its advantages of reducing cost, strict management, high production efficiency, and high security. However, there are also some shortcomings and deficiencies on the premise, such as maintainability, lack of imagination, stability of safe operation, diversity of layout, etc.

Market outlook 2022-09-21

How about the stacking efficiency of the stacking robot?

With the rapid development and optimization of automatic machines, palletizing robots are gradually applied.

Market outlook 2022-09-18

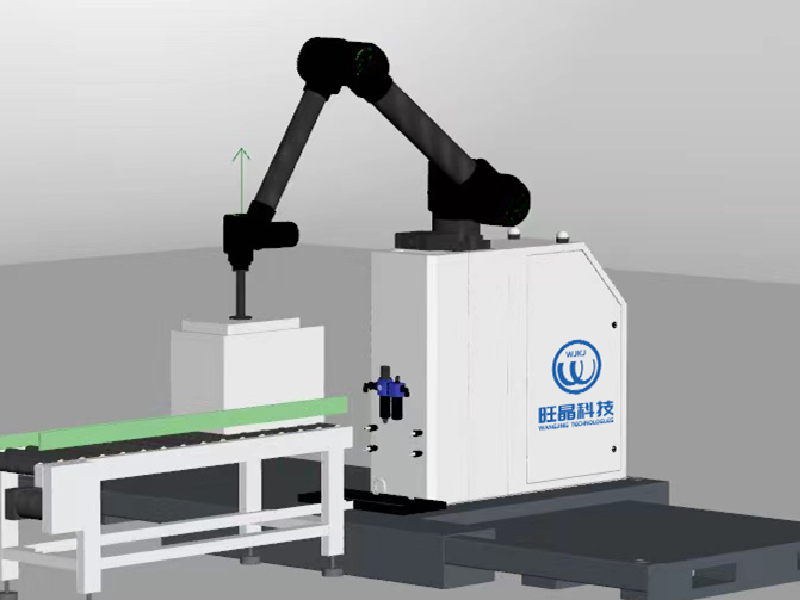

The advantage of this robot is that it can automatically identify what is a cooperative palletizing

The stacking work is completed in the form of a mechanical arm. Stacking is one of the most promising cooperative robot applications, but before introducing in detail, let's start with a simple definition. Palletizing or palletizing refers to the act of placing products on pallets for shipment or storage in the logistics supply chain. Ideally, products should be stacked in a way that maximizes the weight and volume of products under load, and they should be stable enough to prevent products from moving, dumping or squeezing each other.

Market outlook 2022-10-06

This is the important significance of our country to the automatic stacker

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

Market outlook 2022-09-28

What we need to know is that this is the principle of a cooperative palletizing robot

Most of the operations performed by the cooperative palletizing robot are grasping and placing operations, that is, the robot grabs materials from the conveyor belt and places them on the designated position on the pallet along the motion path. Therefore, according to the position relationship between the robot and the conveyor belt and tray when it completes stacking, and considering the obstacles in the movement process, the "door" shaped movement track is selected. It should be noted that when the robot end effector completes the stacking of cartons at different positions on the pallet, the trajectory is in the shape of a "door", and the coordinates of the trajectory end point are different only because the positions of cartons on the pallet are different.

Market outlook 2022-10-06