Advantages and Disadvantages of China's Artificial Intelligence Industrial Palletizing Robot

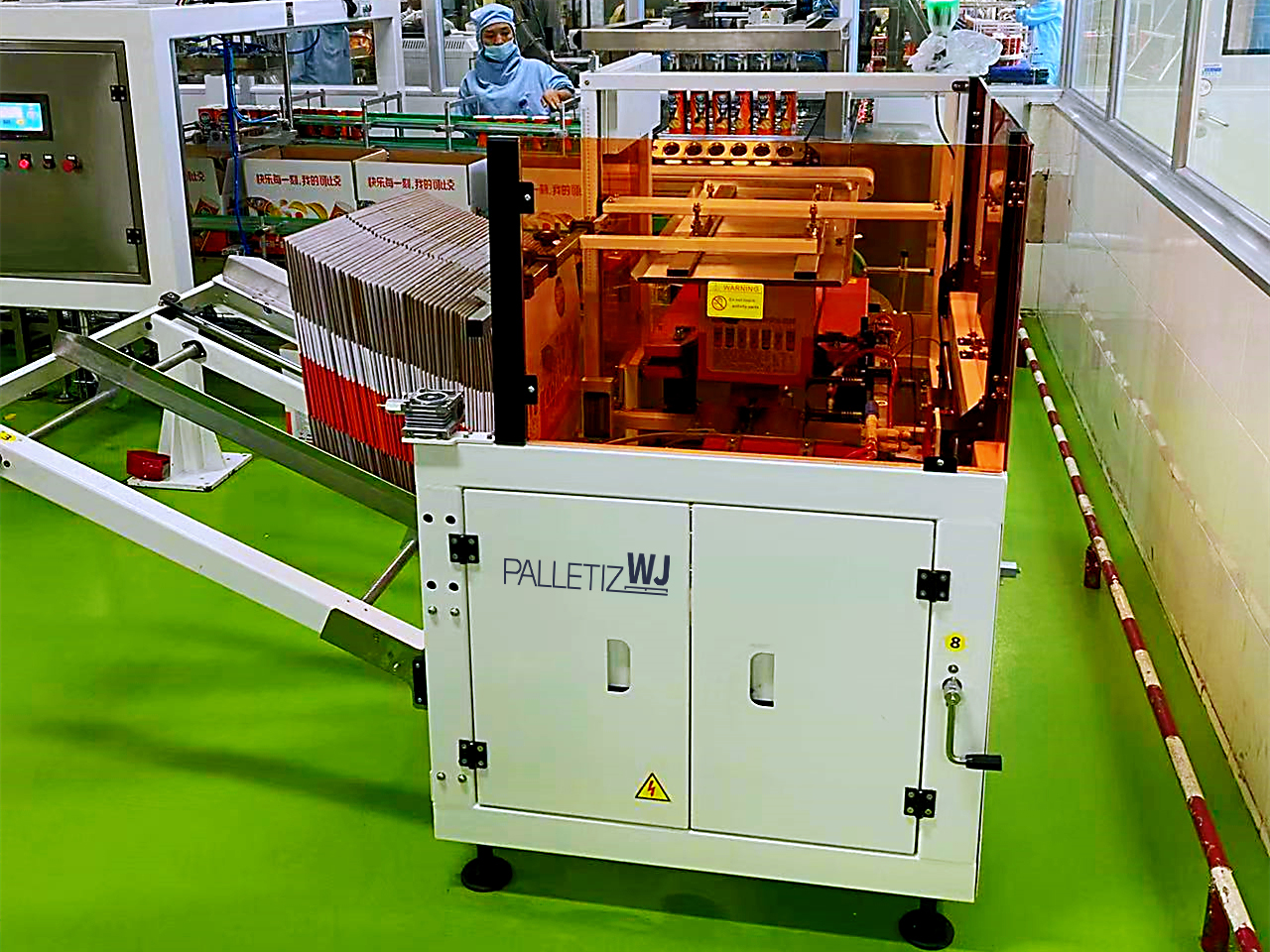

With the development trend of scientific and technological artificial intelligence, in industry, cooperative palletizing robots will undertake more and more tasks in industrial production, leading to industrial robots competing for jobs with people. At this stage, industrial palletizing robots and people have their own advantages. The palletizing robot is warmly welcomed by companies and enterprises for its advantages of reducing cost, strict management, high production efficiency, and high security. However, there are also some shortcomings and deficiencies on the premise, such as maintainability, lack of imagination, stability of safe operation, diversity of layout, etc.

1. Save labor costs and commercial land network resources.

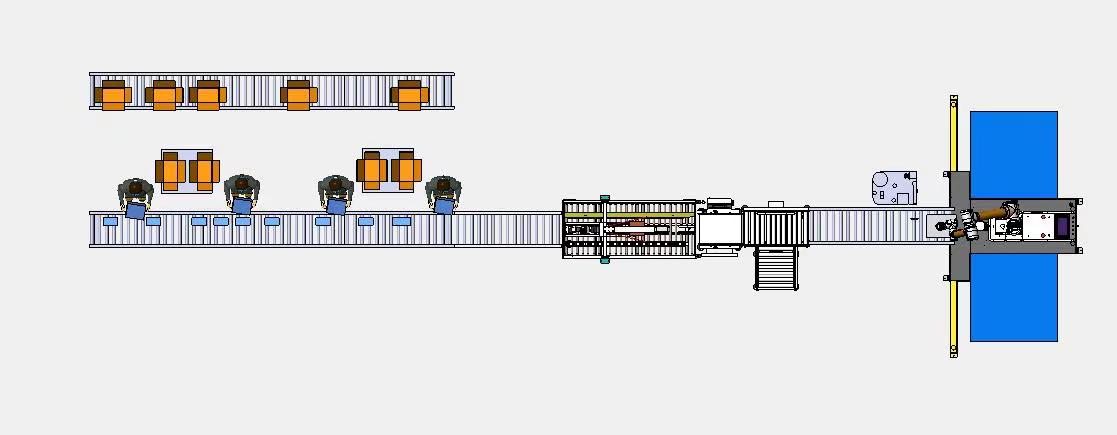

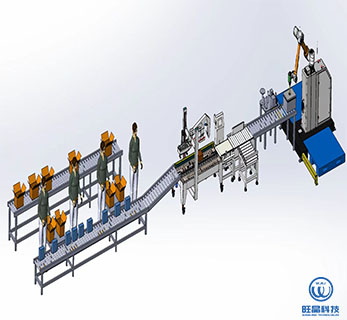

The cooperative palletizing robot can complete 24-hour continuous operation with only a few people to watch over or prepare the program flow in advance. In addition, in the energy based chemical enterprises using industrial robots, the production mode of automatic assembly line is easier to save activity space, which makes the overall planning of the processing plant more compact and saves the cost of water and soil resources.

2. Strict management

The disadvantage and deficiency of human resource application is that many system management staff are not easy to escape from the bottom of the system when implementing the system, and management is often lax. Moreover, employees are not required to guarantee the total production capacity safely during holidays. The investment of employees in commercial insurance accidents is no less than that in industrial robots. The application of industrial robots makes the management of employees in companies and enterprises more concise and clear for colleges and universities.

3. High manufacturing efficiency

In the same production time, the total output of industrial production palletizing robot is fixed, not easy to fluctuate, and the production quality is also high. The application of industrial robots is more in line with the interests of enterprises.

4. Strong security

Stacking and transportation is a complex, dangerous and repetitive work, and it is very easy for humans to be careless or physically tired, resulting in safety accidents. Using the industrial production palletizing robot to work can ensure the safety of employees, and it is not easy to be careless or have safety accidents in work.

inferiority

1. The structure and operation of industrial robots are complex, and improper operation will lead to safety accidents, but this is equivalent to the probability of aircraft accidents. As long as the common problems in actual operation are handled properly, they will not occur generally.

2. Human resources are characterized by independent cognition, judgment and emotion. They can communicate with each other, analyze problems in different situations and solve emergencies. However, industrial robots only operate according to specific procedures and processes, without thinking. If they do not maintain it for a long time, problems will arise and it is difficult to reach the human level.

3. The industrial production palletizing robot used in the general field is developed according to the production process or specific working conditions in the field. If the processing technology changes, the previous equipment may need to be optimized or even redesigned. In order to consider how to layout design and quickly integrate into the new products of the enterprise.

In general, people and palletizing robots have their own advantages and disadvantages. With the continuous development of science and technology, palletizing robots will undertake more and more tasks in industrial production. The processing plant will change the previous operation and manufacturing mode, complete production automation, improve productivity, promote industrial layout adjustment, and form a balance between people and machines