In the future, what can cooperative robots bring to enterprises in the FMCG market

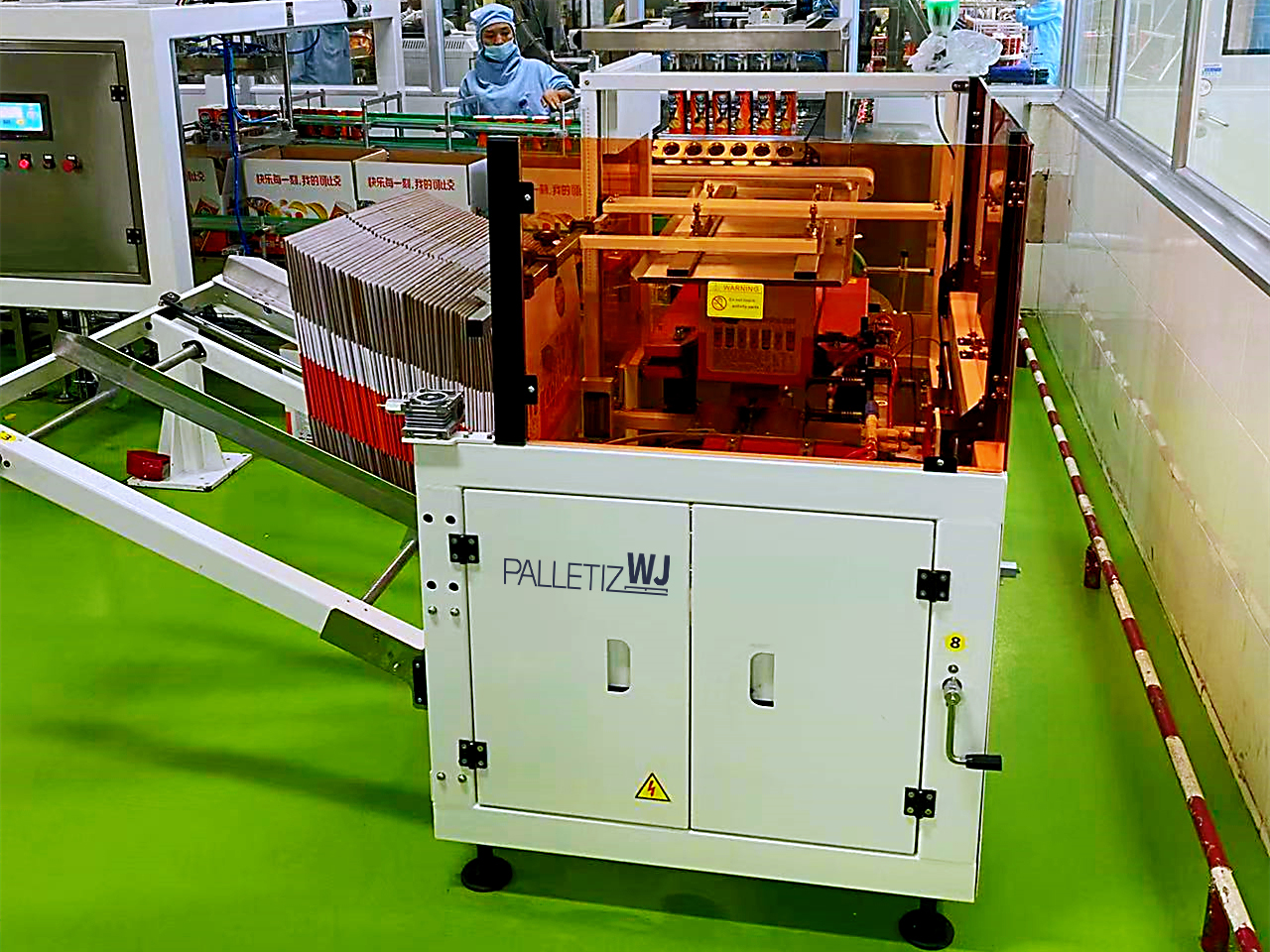

The food manufacturers attending the meeting paid special attention to cooperation and robots to minimize the dependence on human capital and achieve more convenient food solutions. A packaging engineer in charge of large and medium-sized food companies said in the report that about one fifth of the company's plants in North America use cooperative robots, "mainly for loading and stacking. We are ready to invest again in areas that can replace labor.

The majority (78%) of FMCG enterprises that use collaborative robots also aim to improve speed and productivity. The engineering manager of a leading beverage company said in the report, "We believe that collaborative robots will be used for secondary packaging to screen goods and achieve faster freight volume."

68% of FMCG market enterprises use cooperative robots to achieve repetitive tasks and solve problems with standard products. An engineer of the manufacturing project of a large and medium-sized household goods company demonstrated that the cooperative robot can professionally help "move the product from point A to point B, and use signs of various sizes." Similarly, 33% of people use cooperative robots to minimize consumption and human errors in the production process.

In the FMCG market enterprises that use cooperative robots, about half (51%) regard improving the safety of operators as an important temptation to replace daily tasks that may cause harm, such as packaging and palletizing.

Many benefits of collaborative robots pointed out by enterprises in the FMCG market include improving the accuracy of daily tasks, realizing the coordination ability of various functions, improving the utilization rate of production workshops, reducing enterprise costs, etc.

However, the introduction of collaborative robots into the production process of FMCG enterprises does have some defects. More than half (51%) of the enterprises surveyed believe that the lack of internal structure is an important obstacle to the implementation of cooperative robots

Those who noticed the internal structural defects mentioned that the engineering project of integrating and serving cooperative robots lacked professional skills, it was difficult to determine the appropriate application software, and the test of integrating cooperative robots into the current production line. "It may be important to find a better system integrator," said the engineering manager of a large pharmaceutical company. Other internal structural issues include total floor space and lack of professional time.

In the interview with FMCG enterprises who are cautious about the implementation of collaborative robots, about one third (30%) of enterprises said that cost is a problem, and the return on investment and product procurement have reached the cost of later application and maintenance. Original procurement costs and their assembly, integration and training costs.

At present, the lack of technical functions of cooperative robots is also a problem. 22% of FMCG market enterprises emphasize the need to improve the indoor space of collaborative robots, including lightning fast speed, more convenient security protection, precise positioning, customization, flexible transformation and processing coordination.

The deputy director of a large and medium-sized pet food company said, "If we want to deploy a large number of collaborative robot technologies internally, we must consider how the collaborative robot can further improve the overall efficiency of the production line."

One tenth of the FMCG enterprises surveyed by the organization said that the lack of support services prevented them from integrating collaborative robots into the production process, including practical problems such as lack of training and learning to operate.