Comparison between mobile cooperative palletizing robot and industrial palletizing robot

With the development of urbanization and the gradual promotion of industrial production reform and innovation, automatic machinery has become the main power for today's industrial development. The productivity of social development has also ushered in a new peak in the mechanical automation reform in which cooperative palletizing robots replace human resources. Nowadays, there are various types of industrial manipulators. How to choose in the sinking market?

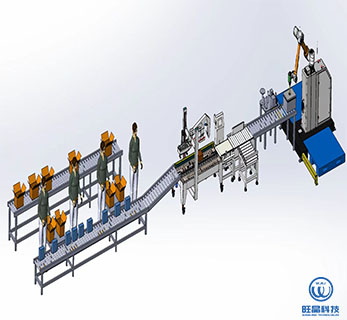

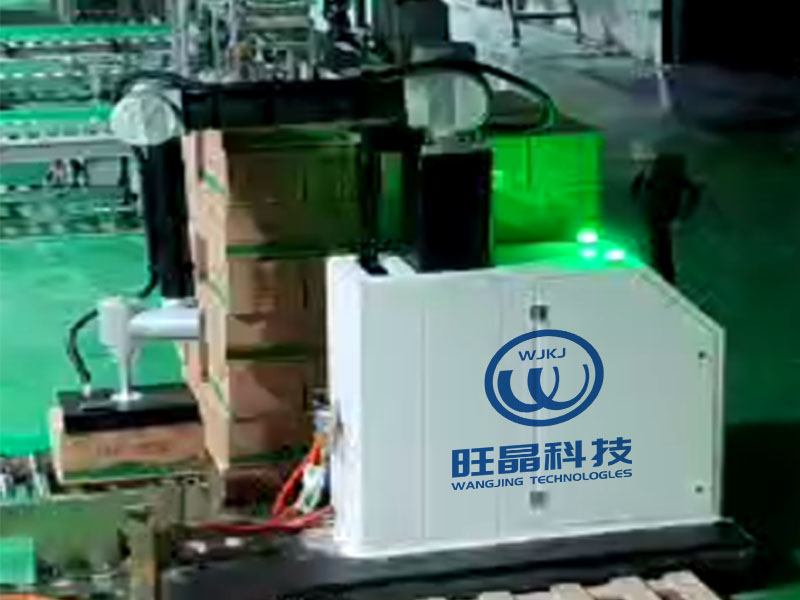

Wangjing Technology is a high-tech enterprise focusing on industrial robots from product development to manufacturing and sales, which is at a high level in the automation robot industry. In today's highly competitive industrial manipulator market, the mobile collaborative palletizing robot developed by Wangjing Technology outperforms the conventional industrial palletizing robot with relatively high market coverage in terms of industrial behavior, and is a popular choice for factory procurement. Its main performance is that everyone speaks with data. The mobile cooperative palletizing robot is a perfect palletizing system software, which can sort and accurately position products according to the conveyor, release manpower and realize the standardization of industrial production. The mobile robot has a small volume and a net weight of only 62kg. It is not only easy to carry and transport, but also has excellent practical effects in various working environments. Moreover, its working environment configuration is simple. It only needs one product import and export, 220v working voltage and gas pipe to operate. It takes five minutes to fully prepare for formal work.

The mobile cooperative palletizing robot is very suitable for assembly line production, and its process is as follows: wooden pallets are placed at designated positions by manpower for palletizing; The mobile robot will swing its special fixture to climb the product and place it on the wooden pallet according to the preset placement method. The whole process does not require manpower and is suitable for production lines with relatively slow speed. Easy to use, stable attitude, can greatly reduce personnel and labor efficiency. Mobile machine equipment not only selects control conversion technology, which makes key coding simple and convenient, but also requires low programming ability of technical operators; At the same time, various humanized designs are installed. On the premise of producing extremely high coordination ability of mechanical equipment, it still has a variety of maintenance design schemes in details, so as to achieve what you want and ensure personal safety in the workflow. At the same time, under the secret recipe management and data visualization design, multiple sets of different types of packaging schemes can be flexibly set and switched with one key, which greatly reduces the time for changing production lines and improves efficiency.

The cooperative palletizing robot has achieved many successes in the floor sales market with high productivity and high cost performance. The future industrial production belongs to intelligent robots and automation. A convenient industrial manipulator with high yield is undoubtedly a good ticket at present. The industrial production of automation technology will be reasonably arranged as soon as possible, and the road of mechanical automation revolution will go further and further in the near future.