What are the application fields of 3D cooperative destacking robot

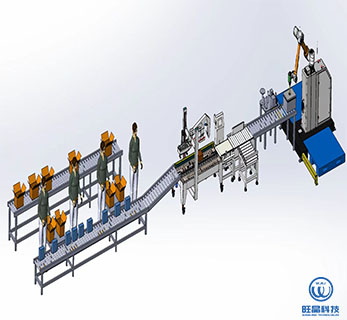

Collaborative 3D destacking robot is widely used in logistics and warehousing, production and manufacturing, outer packaging, production and processing and other industrial production commodity circulation and freight logistics scenarios. Select the plan scheme of 3D camera+machine vision algorithm.

The 3D point cloud information of the object is obtained through the 3D camera, the part and specification of the object that must be unpacked are calculated using the visual algorithm, and the industrial robot is correctly guided to carry out the automatic operation of unpacking according to the control platform.

Market outlook 2022-09-18

Intelligent sorting robot improves work efficiency

With the continuous implementation of industrial intelligence, logistics enterprises are also moving towards intelligence. There is no one to transport. Intelligent sorting has already been used in the transport industry. The birth of sorting robots has greatly improved various work efficiency, saved human costs, and will play an important role in the completion of intelligent logistics

Market outlook 2022-09-20

Portable palletizing robot goes to war to solve the problem of small factory space

With the mature application of artificial intelligence, big data, cloud computing and other technologies, robot manufacturing enterprises have enjoyed huge scientific and technological dividends. According to the statistical report of relevant data, the number of industrial machines put into use in the world has reached 3 million, with a year-on-year growth of 10%. It is estimated that by 2024, the number of new industrial robots in the world will reach about 500000/year. From the data, the demand for robots will increase year by year. On the one hand, robots improve work efficiency, on the other hand, the application of robots also reduces the pressure of manual management in enterprises.

Market outlook 2022-09-30

What should be paid attention to when selecting the sealing machine?

With the continuous improvement of the degree of automation, more and more enterprises are gradually transforming and upgrading from the original manual to production automation. The introduction of automation equipment has improved the production capacity and personal image of the enterprise, thus improving the production efficiency of the enterprise.

Market outlook 2022-09-18

As the most advanced full-automatic palletizer in the world, Huawei is a good helper for enterprise

Many people have only a general understanding of stackers. They believe that the stacker is a simple mechanical equipment used for handling and stacking goods. In fact, the stacker is not just a simple mechanical equipment. Many production workshops have palletizing robots to load, unload and stack goods. The use of palletizing robots is several times more efficient than traditional labor, but it can also reduce the human cost of enterprises.

Market outlook 2022-09-28

Cooperative mobile palletizing robot can improve efficiency and save costs

In many industries, collaborative palletizing robots have been used to replace manpower and simplify work. It is generally used for lightweight practical product packaging. Collaborative intelligent robots put objects or services into small boxes or trays. The intelligent robot of automobile palletizing cooperation can accurately stack small boxes, aquariums, packaging bags, pallets, and packaging cartons in the medium and heavy load areas in the pallet.

Market outlook 2022-09-18

We are now studying the problems faced by palletizing robots

Stacking robot is a kind of industrial robot, which is widely used at present. With the decline of labor rate and the rise of labor cost, palletizing robots are used more and more. Stackers and porters are manufactured in manufacturing enterprises to replace manual post packaging operations.

Market outlook 2022-09-28

This technology is fully automatic palletizer, which is a good helper for enterprise production

Many people have only a general understanding of stackers. They believe that the stacker is a simple mechanical equipment used for handling and stacking goods. In fact, the stacker is not just a simple mechanical equipment. Many production workshops have palletizing robots to load, unload and stack goods. The use of palletizing robots is several times more efficient than traditional labor, but it can also reduce the human cost of enterprises.

Market outlook 2022-09-23