What are the application fields of 3D cooperative destacking robot

The collaborative 3D destacking robot may not be widely used in daily life, but it is still widely used in some industrial fields. Let's take a look.

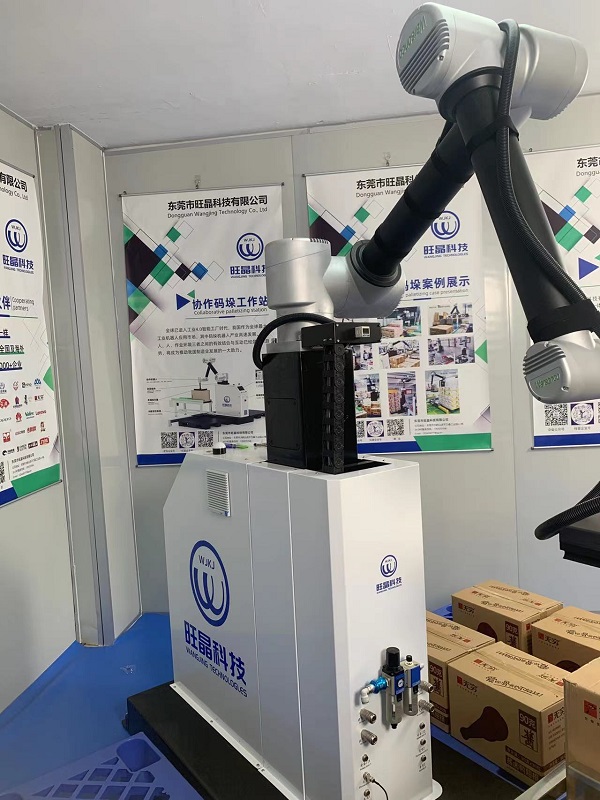

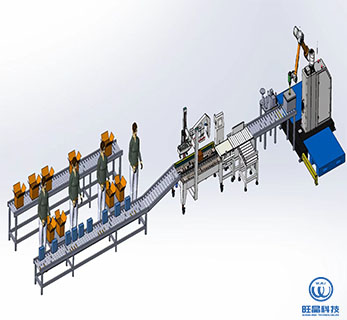

1. Box unstacking

Collaborative 3D destacking robot is widely used in logistics and warehousing, production and manufacturing, outer packaging, production and processing and other industrial production commodity circulation and freight logistics scenarios. Select the plan scheme of 3D camera+machine vision algorithm.

The 3D point cloud information of the object is obtained through the 3D camera, the part and specification of the object that must be unpacked are calculated using the visual algorithm, and the industrial robot is correctly guided to carry out the automatic operation of unpacking according to the control platform.

2. Consumer Electronics Industry

The application of this field is mainly shown in the three major production processes of computer motherboard, parts assembly and the whole equipment assembly.

With the increasing precision of communication products and the smaller and smaller specifications of electronic components, the product quality standards are still improving. Therefore, the need for machine vision for industrial production continues to grow.

3. Soft package unstacking

The collaborative 3D unstacking robot is generally used for the feeding and transportation of powdered and granular objects in the food industry, chemical manufacturing industry and other freight logistics scenarios.