Cooperative stacker safety

PalletizeWJ is an alternative to the standard palletizing system. Using cooperative robots and security level components from industry-leading suppliers, our palletizers meet the security level required for unattended operation in terminal packaging operations.

Cooperative robot

Wangjing Technology uses fully cooperative robots. These robots are certified by the widely accepted European Standards Organization and meet the requirements of the standards.

By utilizing the power and force limitations of each joint, the robot ensures sufficient controlled motion for operator interaction.

PalletizeWJ stacker

The control system of each PalletizeWJ stacker contains three types of PLd safety circuits. They also include an integrated safety controller for monitoring robots, emergency stops, pneumatic and safety scanners (if required).

The design of each stacker conforms to the industrial and cooperative robot system standards of the Robotic Industry Association of the Standards Association. By applying speed and force limits, the stacker meets safety requirements without using hard protection.

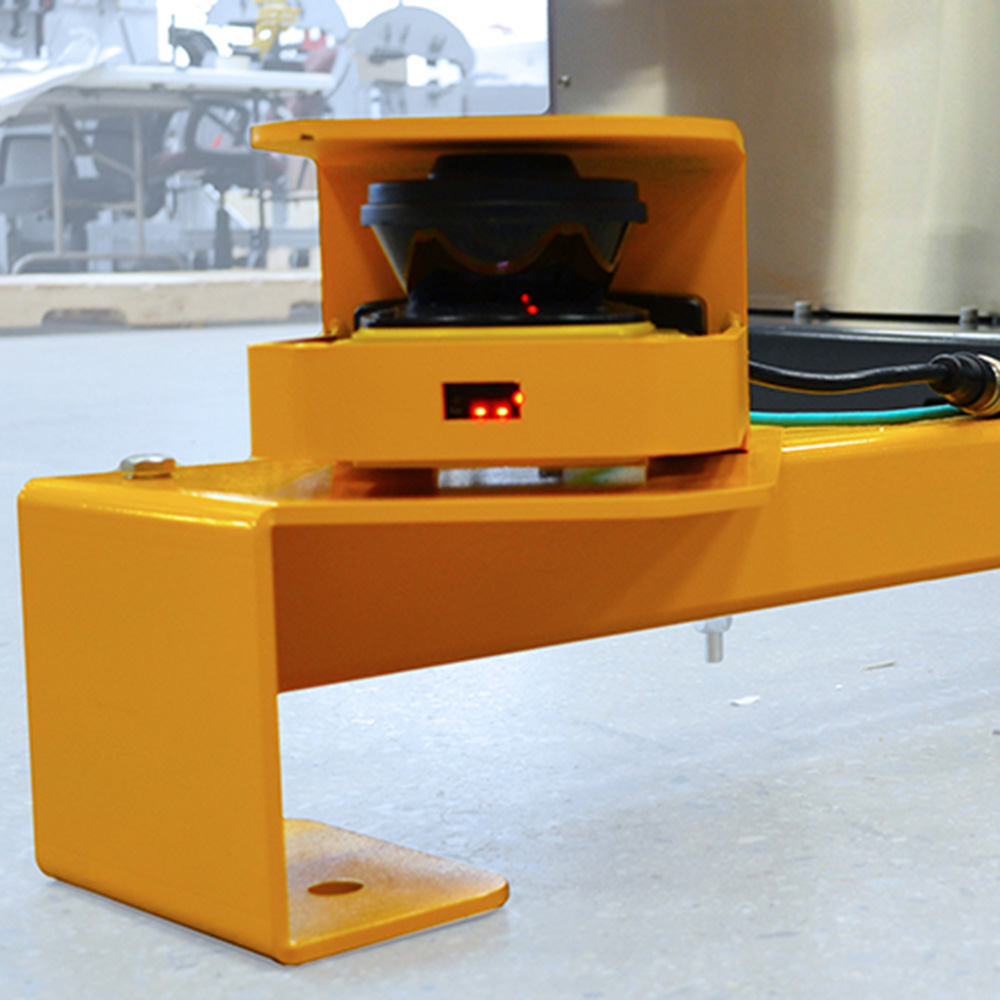

Security Scanner

If the robot needs to move at a high speed, or the application needs to build a pallet that is more than 48 inches high, it is recommended that the security scanner meet the security standards.

risk assessment

Wangjing Technology has hired a third-party security consultant to test the system. The consultant used the risk assessment method to verify that the stacker meets the standard.

Although end users should perform their own risk assessment for each application, the stacker has demonstrated compliance.

Quality Control

Before delivery, each PalletizeWJ stacker will be subject to multi-step inspection to ensure that the system meets all cooperative safety requirements, including verifying the machine manpower settings by measuring the actual impact force.