We believe that AI can help palletizing robots to complete high-risk tasks instead of humans

Stacking robot is a common automation equipment to improve the production efficiency of enterprises. In recent years, the aging problem of China's population is serious, and the development of manufacturing enterprises is faced with the problems of difficult recruitment and high cost of employment management. Therefore, more and more enterprises begin to turn their attention to robots, hoping to use industrial robots to solve the production problems of Chinese enterprises. It used to take more than ten people to complete the stacking work, but now only one stacking robot can complete it.

Market outlook 2022-10-06

Advantages and Disadvantages of China's Artificial Intelligence Industrial Palletizing Robot

With the development trend of scientific and technological artificial intelligence, in industry, cooperative palletizing robots will undertake more and more tasks in industrial production, leading to industrial robots competing for jobs with people. At this stage, industrial palletizing robots and people have their own advantages. The palletizing robot is warmly welcomed by companies and enterprises for its advantages of reducing cost, strict management, high production efficiency, and high security. However, there are also some shortcomings and deficiencies on the premise, such as maintainability, lack of imagination, stability of safe operation, diversity of layout, etc.

Market outlook 2022-09-21

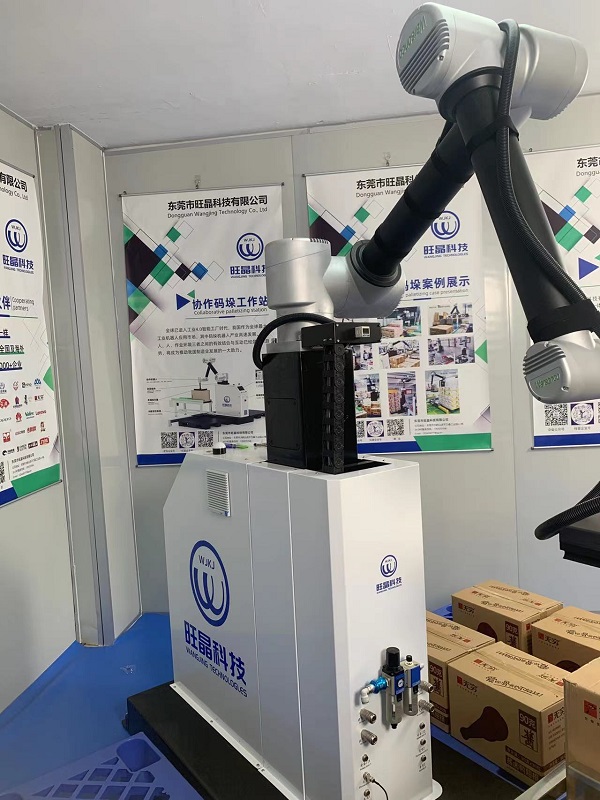

Cooperative mobile palletizing robot can improve efficiency and save costs

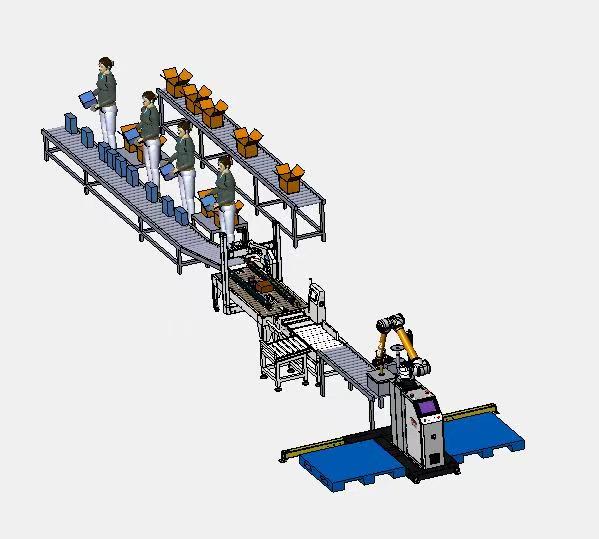

In many industries, collaborative palletizing robots have been used to replace manpower and simplify work. It is generally used for lightweight practical product packaging. Collaborative intelligent robots put objects or services into small boxes or trays. The intelligent robot of automobile palletizing cooperation can accurately stack small boxes, aquariums, packaging bags, pallets, and packaging cartons in the medium and heavy load areas in the pallet.

Market outlook 2022-09-18

What should we pay attention to when small and medium-sized enterprises choose cooperative robots?

Collaborative robots are used in the process of sorting out enterprise related emergencies, and can complete collaborative work that can only be completed by multiple people at a faster speed. This kind of robot is suitable for enterprises with gradual development of industrialization and scale, and can solve many difficult and complex problems. So what should enterprises pay attention to in the early stage of selecting cooperative robots?

Market outlook 2022-09-22

What is the basis for the normal and stable operation of our automatic stacker

Collaborative mobile has fully played the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads.

Market outlook 2022-10-27

This 3D destacking robot realizes hybrid destacking automation and can realize multiple processes

In recent years, a variety of warehouse automation machines and equipment have appeared in China. How to use automated machines to improve the efficiency of warehousing operations and reduce labor seems to be the concern of the warehousing industry at this stage. From process planning to software and hardware design, the specific conditions of the construction site should be fully considered. The invention can improve the limit under complex scenes and achieve efficient operation

Market outlook 2022-11-01

At present, the company has formed a whole industrial chain automatic production line process layout

The advantages of the automatic production line are very obvious, but if the overall planning of the initial overall processing process layout is not good, the advantages of the automatic production line will be discounted. The automatic production line process layout is generally divided into linear layout, zigzag layout, and T-shaped layout

Market outlook 2022-11-03

At present, robots have been successfully applied in many industries, including the working efficien

The definition of collaboration is more widely used in industrial scenarios. The cooperative mobile palletizing robot has replaced and improved the existing industrial robots, and has become the leading technology genre in the robot field with its higher safety factor, reliability and human coordination ability.

Market outlook 2022-11-01