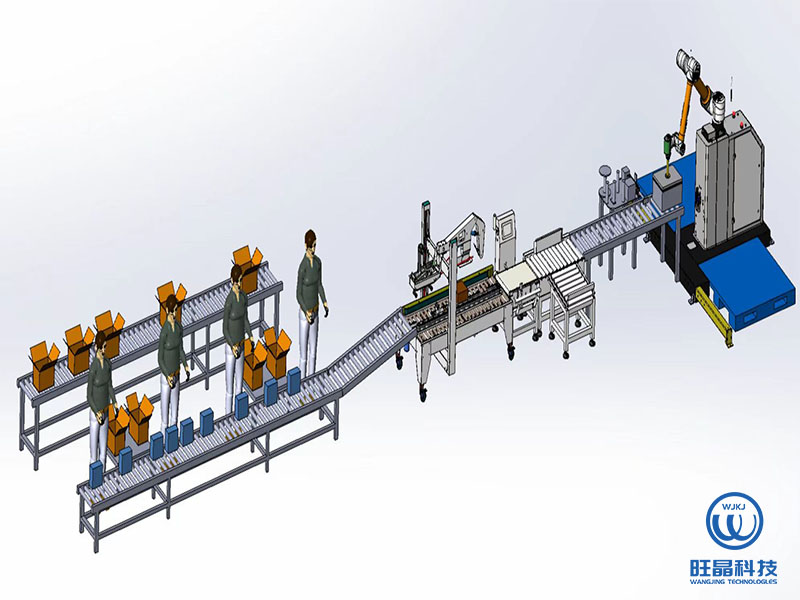

This 3D destacking robot realizes hybrid destacking automation and can realize multiple processes

In recent years, a variety of warehouse automation machines and equipment have appeared in China. How to use automated machines to improve the efficiency of warehousing operations and reduce labor seems to be the concern of the warehousing industry at this stage. From process planning to software and hardware design, the specific conditions of the construction site should be fully considered. The invention can improve the limit under complex scenes and achieve efficient operation

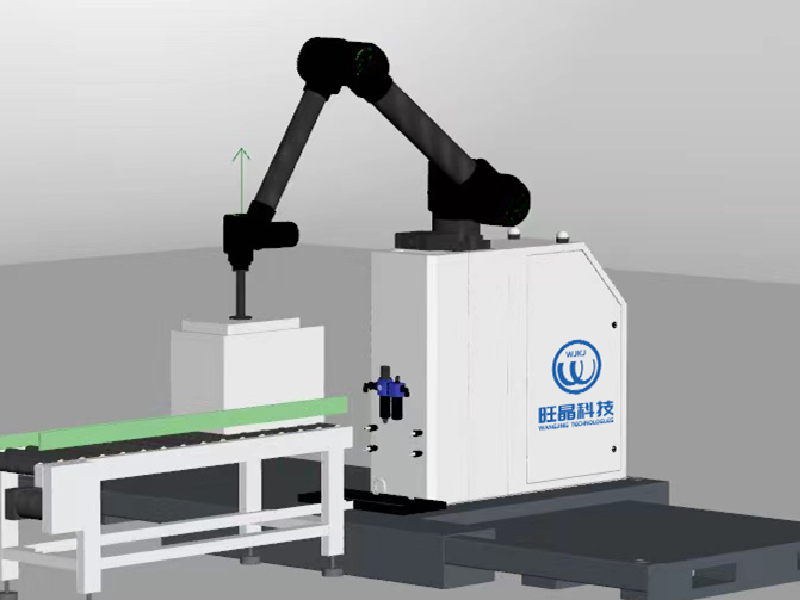

First, because the feed stack type is manually and dynamically coded, the feed stack type is completely arbitrary. It is not suitable to apply template comparison to identify positioning mode.

Softer positioning mode is required to accurately identify precise positioning. Secondly, each stack of cartons has various types, different sizes and proportions, and the total number is uncertain.

This makes the spatial coordinates of each carton inconsistent and requires accurate positioning of the spatial coordinates of each carton.

Subsequently, the pallet size is 1200 * 1000mm, and the uncertainty of stacking height reaches 1800mm. The accuracy level of the sensor is inversely proportional to the installation height and directly proportional to the product size.

The stacking is high and large, and the size of a single carton is small, which puts forward higher requirements for the sensor. Not only precision, but also speed.

Elson's technicians must find a simple and complex answer to intelligently identify an image.

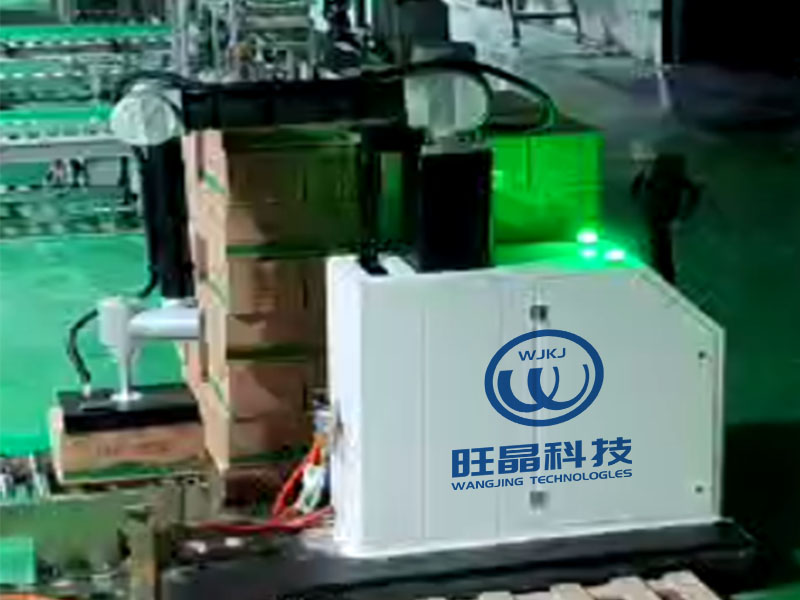

According to the image intelligent recognition technology of the stacker robot, the AT-S1000-01A mobile phone positioning system can identify and calculate the direction and spatial coordinates of each carton without typing the carton model, specification and other relevant information in advance, and guide the robot to climb accurately. The AT-S1000-01A mobile phone positioning system can calculate the actual size data information of each carton in batches, judge the model and specification, record the total number of pieces, and seamlessly connect with the WMS system. It can be adjusted according to the software data, further saving human resources and improving work efficiency.

The stacker robot has the characteristics of wide viewing angle and high precision, which can easily hold the precise poverty alleviation positioning of the 1.8m high stacker. With the efficient popularization of various automated logistics machines and technologies, the cost of machine replacement will be greatly reduced.

To improve the efficiency of warehousing and logistics is undoubtedly the key to win the future industry competition.