What is the working principle of palletizing robot

In our daily life, we often see or use palletizing robots. Just like when we go to the supermarket, many goods have to be put in high places. Some are manual and some are automatic. If manual operation is used, it is generally used in some small supermarkets, large malls, etc. However, in some large shopping malls or warehouses, it is not realistic to change the labor force. At this time, we need to set some programs to let the palletizing robot put in a specific position according to the set program.

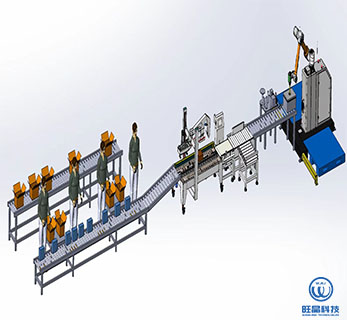

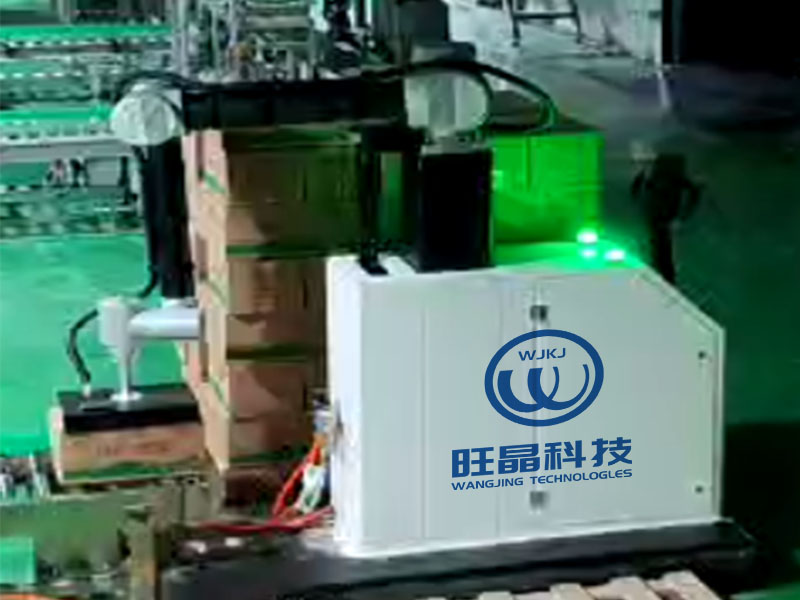

Stacking manipulator is a high-tech mechanical equipment. The customer must input data information in advance, and the automatic stacking is operated by the automatic control system of the stacker equipment according to the information. It can put the same total number of objects into one address according to a certain process, and enhance the standard and beautiful stacking according to the preset information, so as to facilitate future transportation or storage.

The appearance of stacking manipulator can improve the working efficiency of a factory to a certain extent, reduce the labor efficiency of the stacking workers in the factory, and allow workers to have free time to do other work, thus saving time. It can not only delay stacking, but also complete the production and delivery of other brands.