In this way, automatic packing can meet the needs of various enterprises.

In the automatic packaging machine, it is the core of the entire packaging line system. Although packaging machinery is not a machine for directly producing products, it is necessary for production activities.

Packaging equipment is used to complete transportation and packaging. It is to pack and seal the finished products in a fixed quantity according to a certain placement method, and then put them in the box together with the fixed quantity materials in the subpackage, and then seal or seal them.

Container forming (or unpacking), metering, loading, sealing and other functions. The overall operation of the automatic packaging machine is stable and reliable, the bagging is firm and beautiful, the configuration is high, and the equipment is simple to operate and easy to maintain.

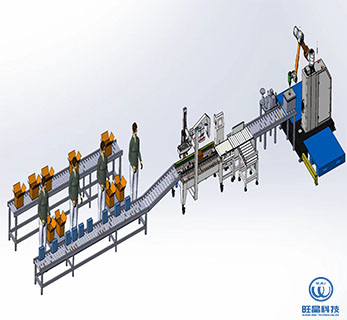

First, the automatic packaging machine is widely used and covers a small area.

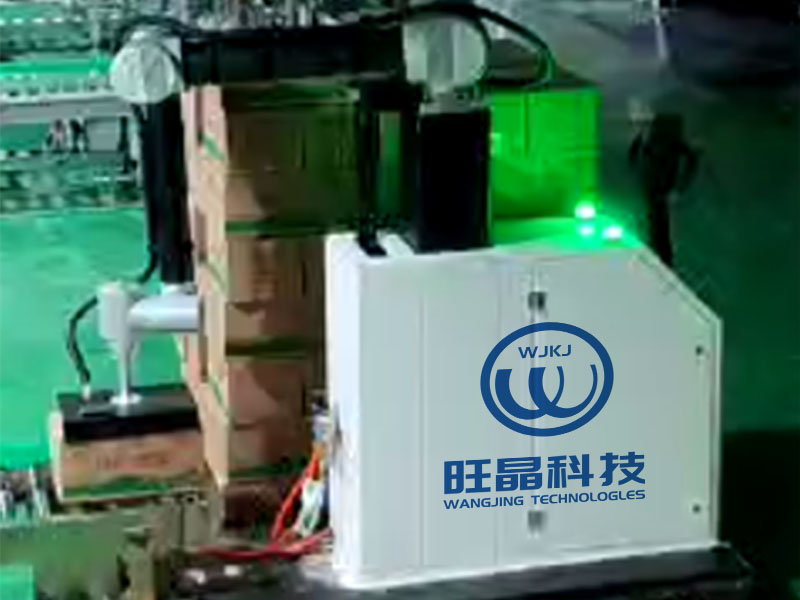

It is suitable for automatic packaging and loading of bottles, cans and barrels of various specifications to complete the packaging production line.

The automatic packaging machine can automatically sort and load into boxes according to the requirements of packaging quantity. After packing, the products in the box are automatically sent to the conveying roller and automatically connected to the unmanned production line.

2、 The automatic packaging machine is light in size, with auxiliary pulley, flexible in movement, convenient in installation and debugging, and the body can be customized according to user requirements.

3、 The automatic packaging machine uses vertical cardboard for storage. The cardboard can be replenished at any time and anywhere, without stopping the machine, for a longer time and more convenient packaging.

Suction, unpacking, forming, bottom folding, back sealing and other complete packaging processes.

IV. Automatic packing machine is suitable for carton packing of various sizes. If you need to change the carton size, you can adjust it manually, operate it alone, or use it together with the automatic packaging production line.