In the field of intelligent manufacturing, palletizing robot has incomparable advantages over manual

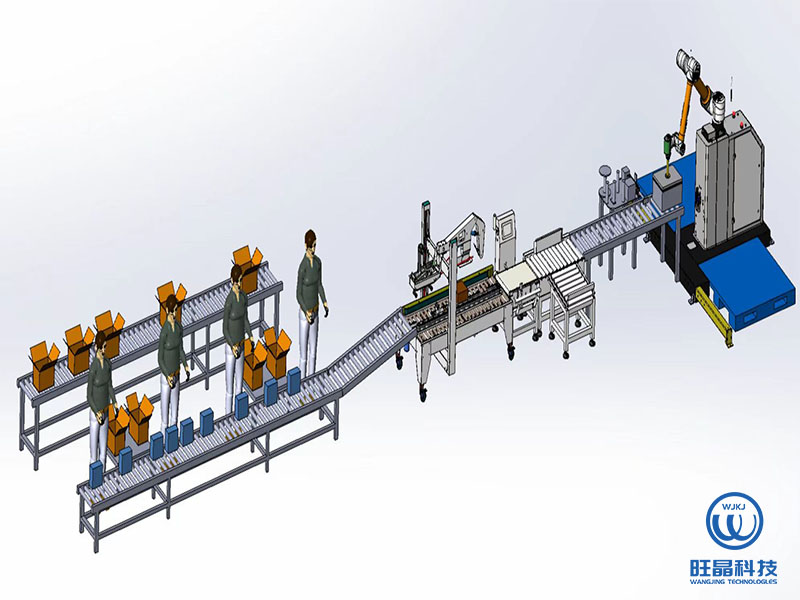

As we all know, it is very difficult to move, place and store goods manually in the warehouse. If only relying on manual handling, it is impossible to achieve efficient storage. Therefore, the degree of automation of the warehouse is getting higher and higher, and the palletizing robot is a very common one.

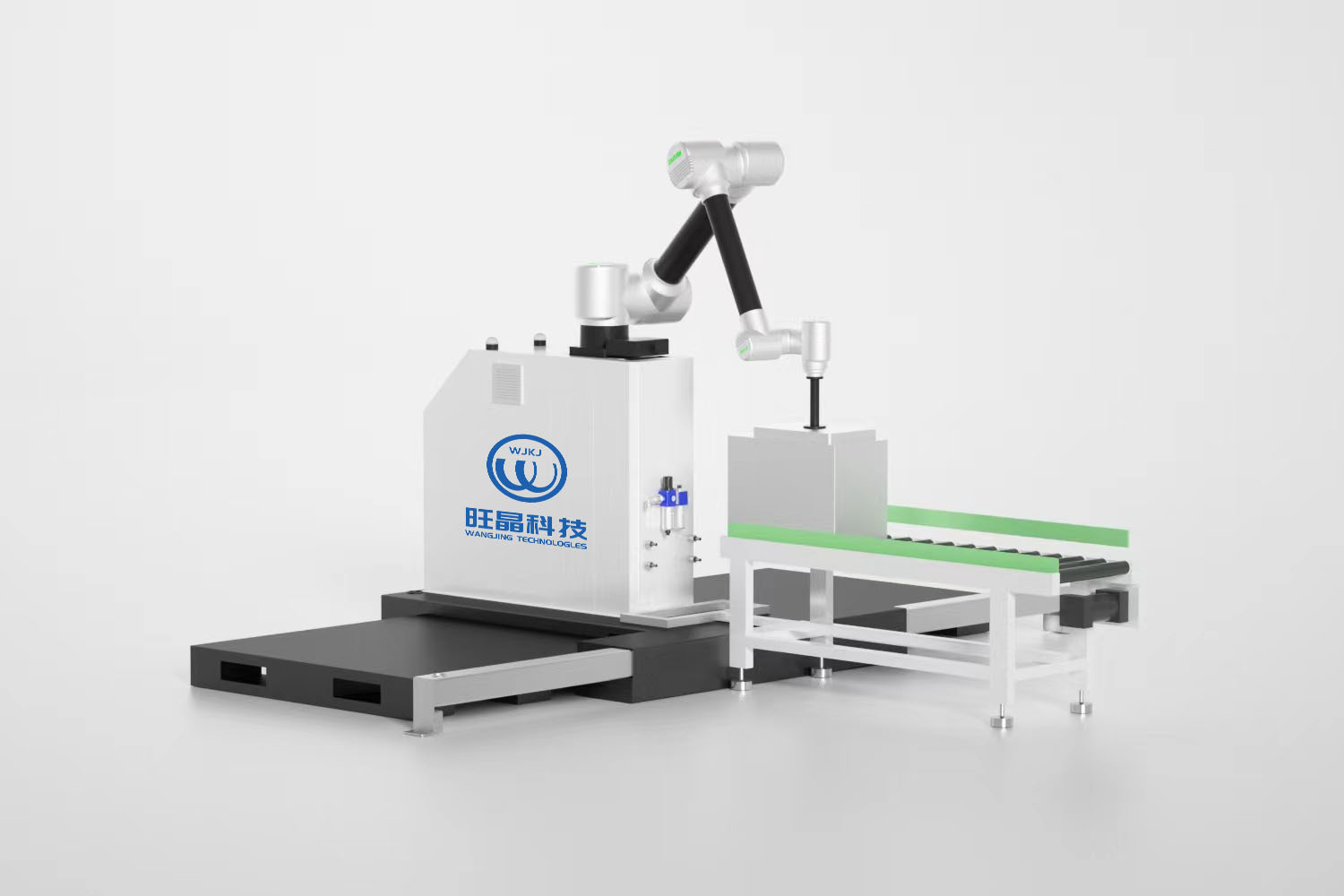

The main responsibility of the palletizing robot is to stack the products on the pallet according to a certain arrangement and automatically stack them. It can be stacked and launched in multiple layers, which is convenient for forklift to transport to the warehouse inventory. How can the stacking robot help enterprises save costs?

1. Save warehouse area.

The stacking robot can stack the goods layer by layer to the highest level, thereby reducing the floor area. At the same time, the stacker can remove the stacked goods layer by layer, and there is no problem in handling.

2. Save labor costs

There is no doubt about cost savings. Whether manual operation or manual handling, a large number of human resources are required. This cost will be completely saved by using a fully automatic stacker.

3. Higher processing efficiency.

Manual handling, one person can not move too much goods in an hour, especially piling up to high places, which is inefficient. The automatic stacker does not have this problem. It can complete high-rise stacking. The goods will never tilt or collapse.