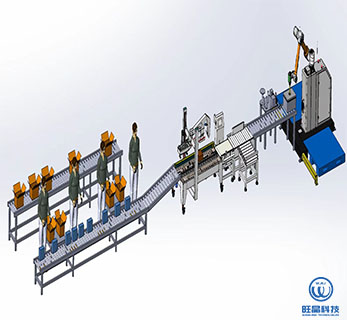

The robot adopts a fully automatic palletizing robot, automatic palletizing, automatic assembly line

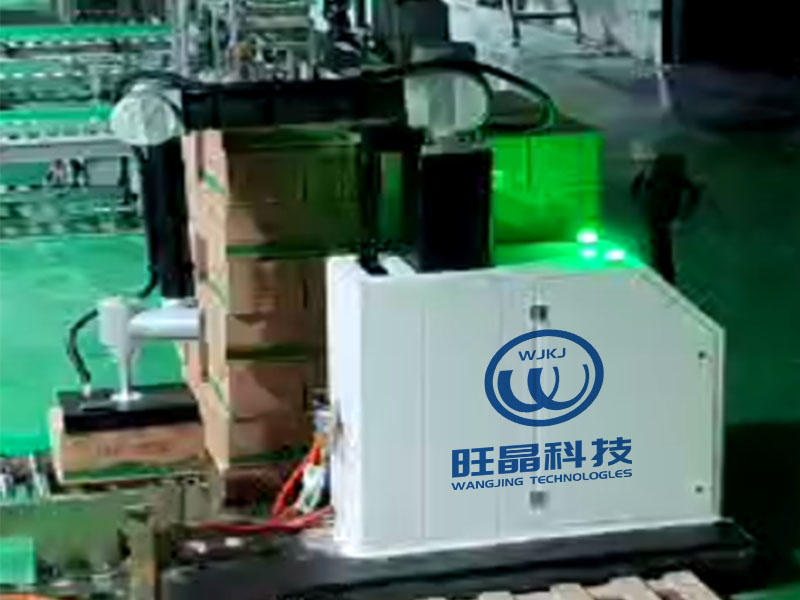

With the development of science and technology and the shortage of labor force, many factories and workshops choose unmanned full-automatic palletizer robot for automatic palletizing, which not only saves costs, but also improves production efficiency. The automatic palletizing robot usually palletizes the bags, boxes, barrels and other materials on the production line to the hauling line according to the instructions set at the end of the production line. Finally, it is stored in the warehouse with a forklift.

According to different product types and actual needs, users can program the robot stacker, manually input instructions, how to stack, how to stack, what kind of stacking type to code, and how many layers to stack. After setting, they can be unattended during production, and only manual forklifts can store stacked pallets.

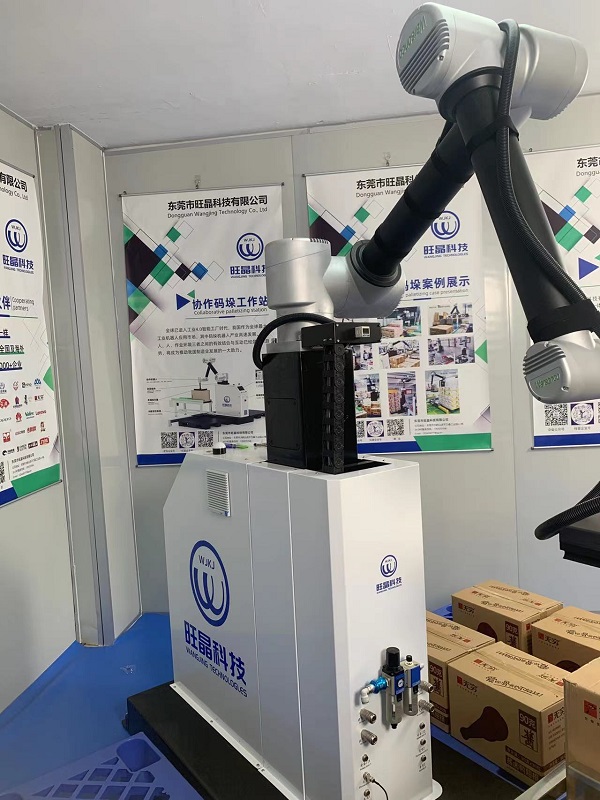

The automatic stacker can be divided into several types according to its own shape. One is an arm type single gripper robot, which can replace different mechanical grippers according to different items to be stacked, and the other is a coordinate column type stacking robot. The standard model of coordinate stacker is X, Y, Z axis, which can expand a rotation axis C axis. The servo closed loop control mode is adopted, and the coordinate position will not be lost in case of power failure. Similar to the robot operating system, the system is equipped with a hand-held controller, which can customize macro programs and carve interfaces according to user requirements.

In industrial application, coordinate stacker can realize automatic control, repeatable programming, multi-function, multiple degrees of freedom, spatial right angle relationship between degrees of freedom, and multi-purpose manipulator. It can carry objects, operate tools and complete various operations.

There is also a high-level stacker, which is also a kind of fully automatic stacker. The host is highly integrated, driven by servo motor, simple and durable structure, automatic refueling and maintenance, low noise, accurate control, and various stacking types.

These fully automatic palletizing robots can replace manual palletizing, and users can choose their own palletizing machines according to the actual needs of their factories.