Therefore, we believe that it is self-evident that palletizing robots can reduce human costs and enh

Stacking robot can reduce labor cost and enhance enterprise competitiveness. Due to the high demand and dependence on labor in manufacturing, the labor cost in manufacturing is relatively high. Public data shows that the human cost of most manufacturing enterprises accounts for about 38% of the enterprise income, so how to reduce the human cost and improve the competitiveness of enterprises is very important for many manufacturing enterprises!

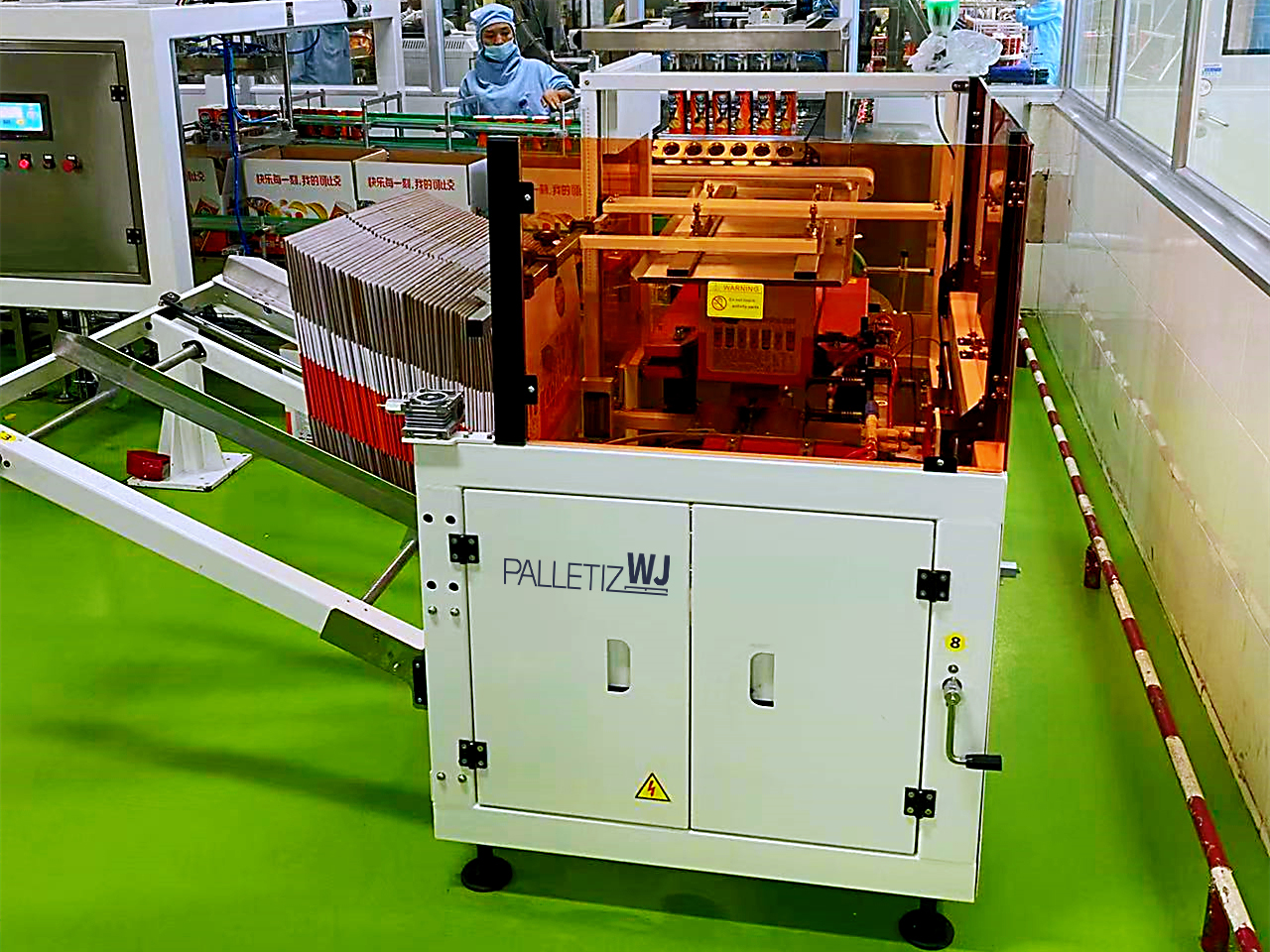

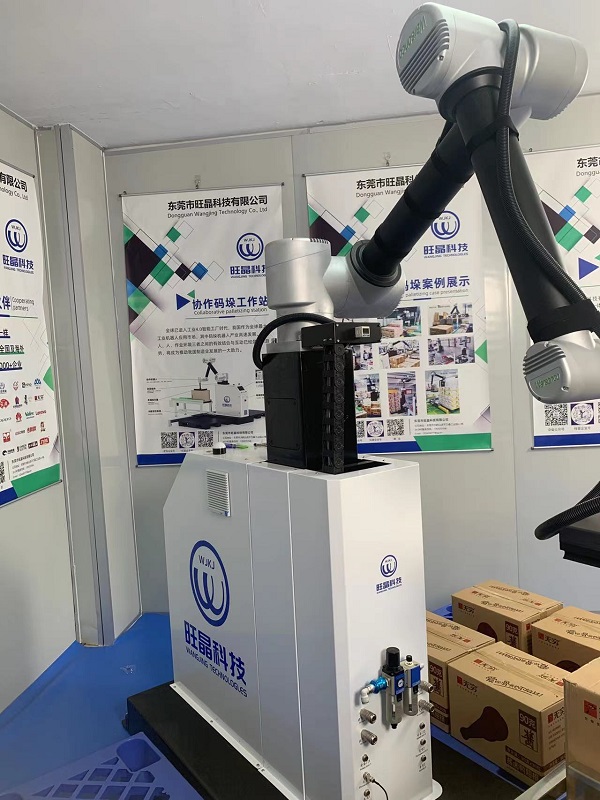

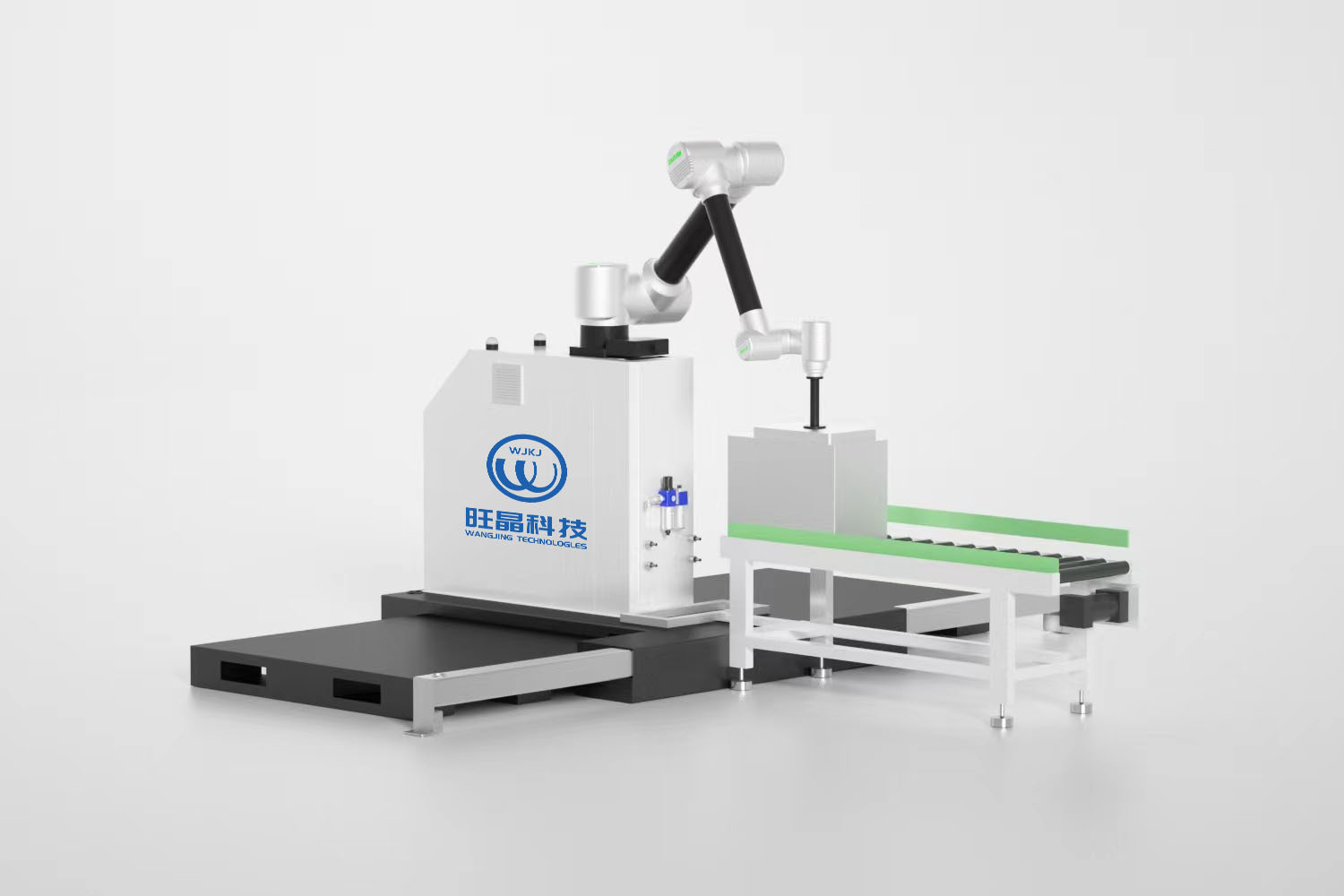

Stacking robot is a kind of robot used for stacking products. The palletizing robot can be programmed according to different product types and actual needs, so as to improve the productivity of palletizing. The palletizing robot has a wide range of types and specifications, which can be used in various environments and has a wide range of applications. Reasonable use of automatic stacker can greatly improve the productivity of enterprises and reduce the human expenditure of enterprises.

As an indispensable part of the enterprise production line, the palletizing robot greatly frees the hands of the palletizing workers. A palletizing robot works normally for 8 hours, which is equivalent to the workload of 3-4 palletizers. Compared with manual operation, the palletizing robot can work 24 hours without interruption, and the normal production efficiency of a palletizing robot is more than ten times that of a palletizer. As an indispensable member of the industrial assembly line, the palletizing robot replaces manual palletizing, improves the working efficiency of the enterprise, and saves the cost of the enterprise.

The palletizing robot can work 24 hours, and the robot can replace the workload of many workers, thus saving a lot of human resource costs, reducing employees every year, and improving efficiency! The machine is suitable for feed, fertilizer, flour, cement, chemical industry and other industries. It can meet a variety of bagging and stacking methods, and can automatically stack according to certain rules and methods, which is convenient for storage, loading and unloading and transportation.

The palletizing robot not only improves the work efficiency, but also improves the overall image of the enterprise, reducing the production and operation costs and human costs of the enterprise. It is precisely because of these information advantages that palletizer talents are constantly developed and widely used in the manufacturing field, which not only effectively reduces the human cost, but also greatly improves the competitiveness of an enterprise!