Through technical innovation, the palletizing function is realized to improve the industrial product

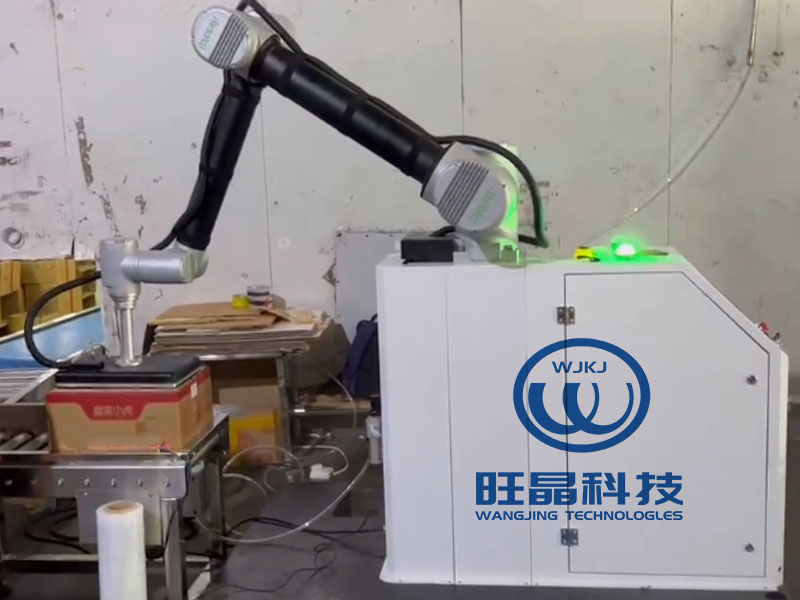

With the continuous progress of industrial science and technology, industrial production requires higher and higher loading and unloading speed. Traditional manual palletizing can only be used under the conditions of light materials, large changes in size and shape, and low throughput, which cannot meet the needs of industrial production. Robot stacker came into being.

Robot stacker is the extension and expansion of workers' hands, feet and brain functions. It can replace people working in dangerous, toxic, low temperature and high temperature environments. It can help people complete heavy, monotonous and repetitive tasks, improve labor productivity and ensure product quality.

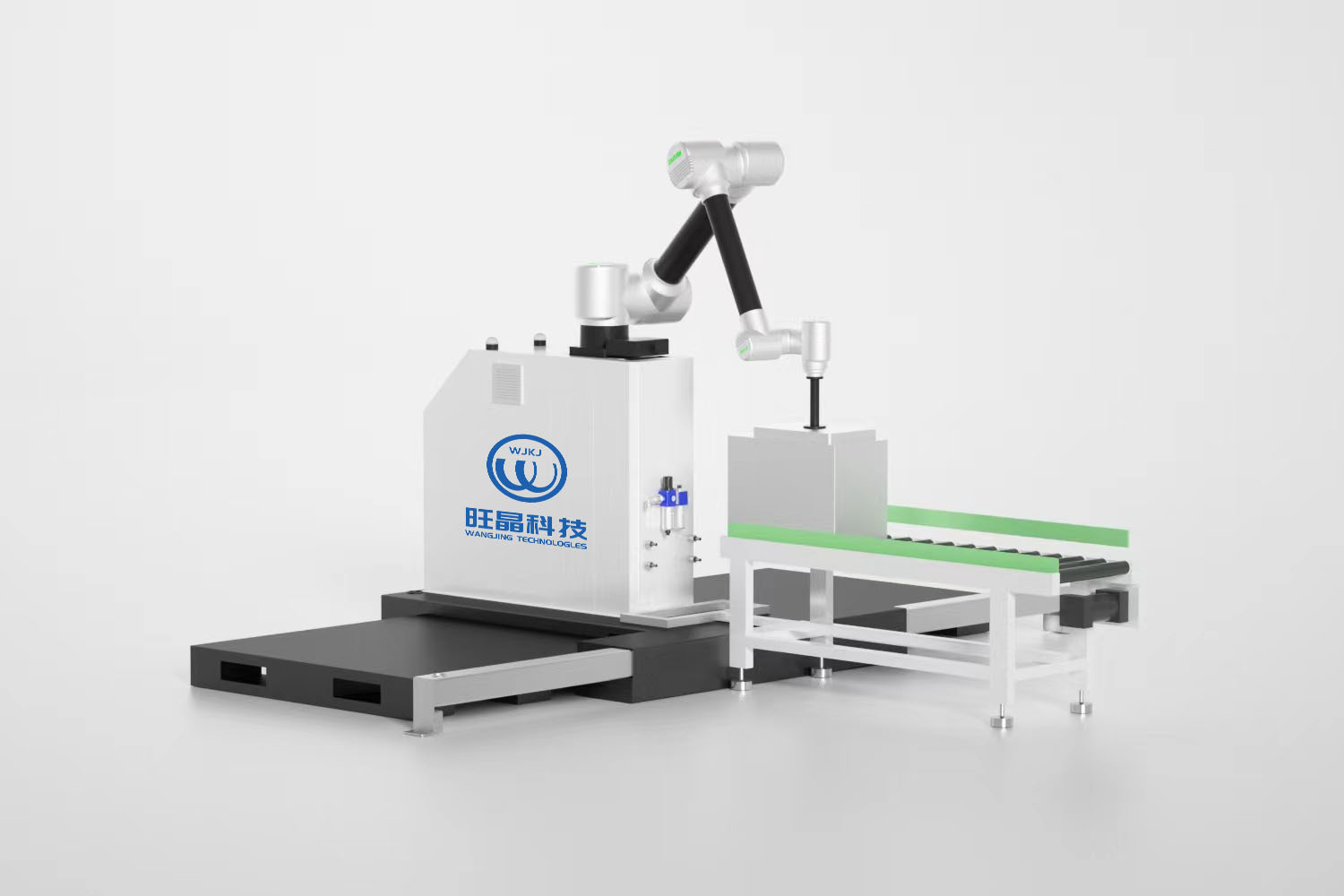

Key components of palletizing industrial robot production line

1. As an important part of the stacking robot, the working performance of the stacking manipulator includes high reliability, simple and novel structure, low quality and other parameters. This is of great significance to the overall working performance of the stacking robot.

2. According to different products, different types of mechanical grippers can be designed, which has the advantages of good stacking quality, wide scope of application, low cost, etc., and can well complete the stacking.

The use of robot stacker has improved the packaging efficiency, improved the efficiency of enterprises, and reduced the production cost and labor cost. Because of these advantages, robot stackers are used by more and more enterprises, creating value for enterprises