Characteristics and Research Scenarios of Stacking Robot

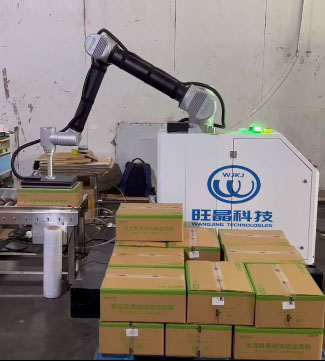

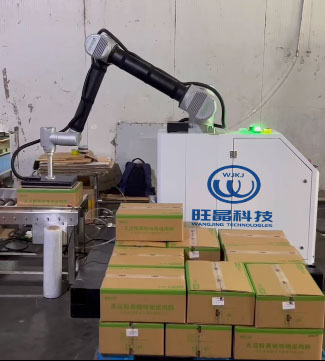

The cooperative palletizing robot is mainly composed of manipulator, wrist, wrist adjustment mechanism, arm mechanism, rotator, servo drive system, base and other components, with four degrees of freedom of body rotation, horizontal and vertical movement of arm mechanism, and wrist rotation. What are the main components and application research scenarios of the system with the cooperative palletizing robot?

1. Manipulators are palletizing robots The main research material can be aluminum alloy profiles, with the characteristics of light development weight and more flexible movement. Different grabbing forms are adopted according to different material packaging forms.

2. The wrist is a lever that can be connected between the arm mechanism and the work analysis device system to support the work control device and determine its position and posture.

Features of palletizing robot system:

1. Simple structure, few spare parts, low failure rate of spare parts, reliable performance, simple maintenance and inventory; Few spare parts

2. The operation method is simple, which can be used for teaching dialogue teaching, and can automatically generate programs;

3. The working radius of space saving is large, and the interference space is effectively controlled. It is conducive to improving the overall design and layout of the enterprise's production plant, and can reserve a larger storage area for the warehouse;

4. Strong applicability. When the size, volume, shape and overall dimension of the tray of the enterprise's products change, it is only necessary to make some modifications on the touch screen, which will not affect the normal production of customers. Even the collaborative stacking robot can stack and package two production lines of different materials at the same time;

5. Low energy consumption. The power of the traditional mechanical automatic stacker is about 26kW, while the power of the stacking control robot is 10kW, which can greatly increase and reduce the operation and management costs of the production enterprises.

The cooperative stacking robot is suitable for setting parameters according to the requirements of different material packages, stacking sequence and layers to realize the stacking operation of different types of material packages. Applicable to warehousing, manufacturing, airport, port, tobacco, beverage, packaging and other industries.