Equipment Performance and Selection of Cooperative Stacking Robot

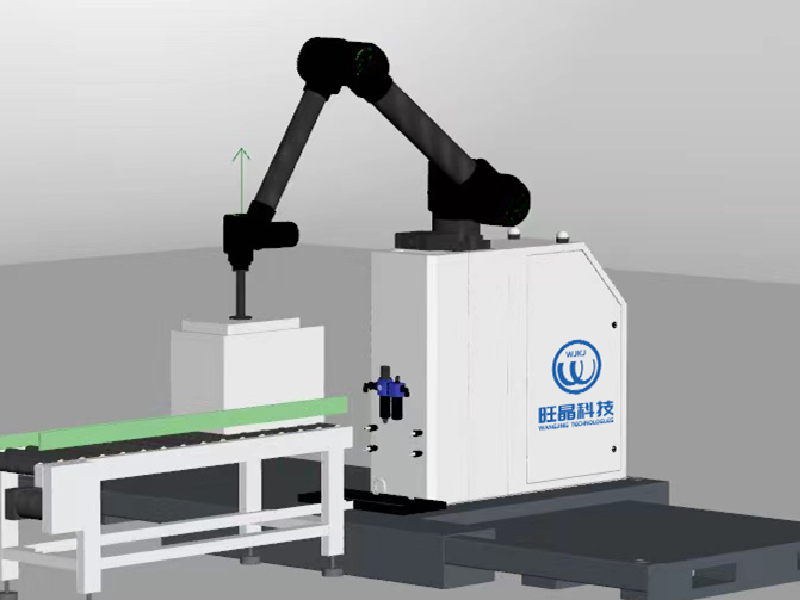

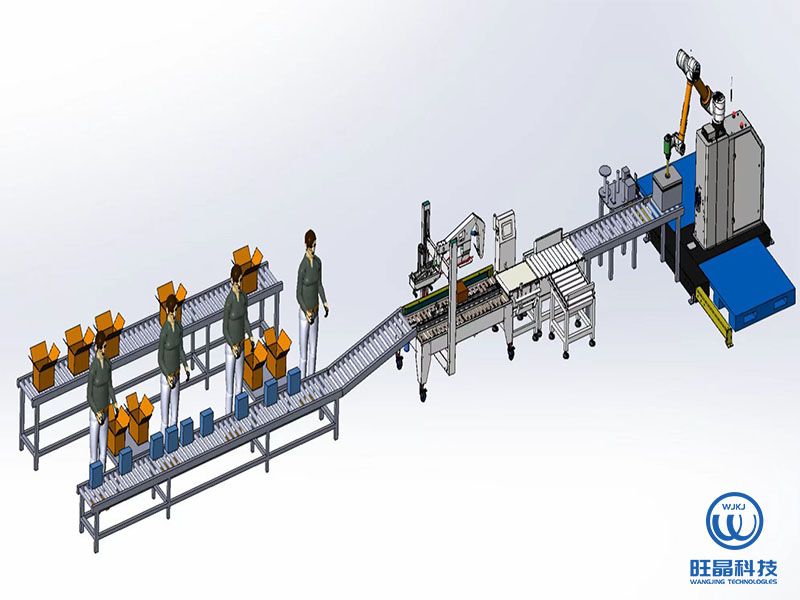

As manual handling and palletizing cannot meet the needs of industrial production, R&D and production of automatic fully automatic cooperative palletizer continue to accelerate. The structure of automatic handling and stacking machine is mainly composed of power distribution cabinet, main stacking behavior, plastic and cosmetic treatment of packaging bags, bag conveying, tray collection, filling, handling and stacking.

Full automatic cooperative stacker:

1. Wide stacking coverage, convenient for stacking, transportation and logistics.

2. Develop towards the direction of high output import substitution, with faster stacking speed and large manufacturing output.

3. Improve product quality and reduce labor efficiency.

Fully automatic cooperative stacker is used to finalize the bag forming the assembly mode, and convenient machinery for automatic delivery of goods is comprehensively considered, thus saving the indoor space occupied. Many manufacturers are very concerned about the brand when purchasing full-automatic cooperative stackers. They pay attention to famous brands because if they find a good manufacturer of fully automatic handling stackers, they can buy products with more guaranteed quality and more appropriate prices. The key function of the automatic handling stacker is to carry and stack the products on the pallet, and then send them to the warehouse. Now, many manufacturers will use automatic handling and palletizing machines to carry out actual handling and palletizing operations. The application of automatic palletizing machine can effectively improve the efficiency of factory palletizing, reduce the cost, reduce the time spent on palletizing, and save manpower. So how to choose a fully automatic handling stacker?

The full-automatic cooperative stacker can classify the products according to a certain arrangement, and then stack the products to a preset position according to the set quantitative analysis. According to the automation level of fully automatic cooperative stacker, it can be divided into upper stacker and stacker robot. When selecting the automatic stacker, the customer should make a choice according to his own actual situation. If the types of bags used by the user are very small and the number of bags is very large, the stacking robot can be used for manufacturing. If there are not many bags to be handled and the requirements for working efficiency are not high, the upper stacker can be selected.