Digital transformation has become the inevitable trend of the development of the industrial Internet

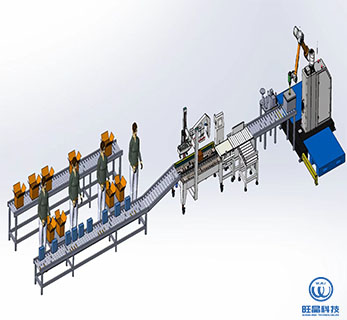

Mass production of products in all industries is inseparable from palletizing In the past, we relied on manual palletizing. More than ten people completed the handling and stacking work together. High labor intensity, low stacking quality and high turnover rate are not conducive to health. With the rapid development of modern science and technology, labor shortage and rising labor costs, robot handling and palletizing production has been widely used, promoting the development of the industry.

In some manufacturing industries, some factories still use traditional manual loading and unloading and stacking operations, which are characterized by large labor volume, high management cost, low loading and unloading rate, and high labor intensity, and are prone to industrial accidents. Faced with labor, material resources, time value and product cost, some factories have gradually lost their competitive advantages due to fierce industry competition. In order to find a competitive advantage, we need to solve various problems in the production process to achieve faster, cheaper and higher speed. The application of palletizing robot has solved the problems of enterprises and enterprises.

The application advantages of coordinate stacker robot are as follows:

1. It can effectively and accurately move the manipulator from one position to another for manipulation;

2. According to the production process requirements, complete the transportation, loading and unloading and handling of workpieces according to the scheduling procedure, duration and location;

3. Effectively replace workplaces with high temperature, high pressure, dust, noise and radioactive pollution.

4. It has the advantages of high flexibility, high stability, high work efficiency and high precision.

The collaborative palletizing robot realizes factory processing automation, improves processing standards and management level, improves work efficiency, reduces labor and time costs, greatly improves operation stability, and ensures that product quality is not affected by other factors.

Coordinate stacker robot products have the following characteristics:

1. Full Chinese human-computer interface color touch screen control.

2. Fault self inspection function, abnormal action alarm indication, and control panel indication of abnormal points.

3. Compact mechanical structure and small space occupation.

4. Servo positioning function is adopted, which is more stable and saves time.

5. The body is made of carbon steel, which is beautiful overall.

6. One machine can be used for multiple purposes, and multiple stacking procedures can be adjusted quickly, so there is no need to worry about changing stacking products.

7. The assembly line can be used for unmanned production.

8. No glare angle, which can control the quality and reduce the production cost. Suitable for corrugated paper, plastic boxes, barrels, bags, etc.

9. Automatic control, reprogrammable, motion executed according to program.

10. Able to work in harsh environment for a long time.

Compared with the traditional stacking method, the stacker robot can realize the automation of stacking activities, making stacking simpler and more suitable for different packaging fields.

In addition, the size, shape and material requirements of packaging make stacking more complex. However, different packaging requirements can be addressed by adjusting flexible mode requirements or providing appropriate end arms.

All factories need palletizing, and highly automated palletizing robots are widely used. It is troublesome to stack manually, which imposes great pressure on employees and is inefficient. According to the characteristics and classification of materials to be transported, the packaging team can stack hundreds of items every hour. The stacking robot can effectively classify materials while maintaining their shape and characteristics. They play an important role in the handling of production lines and container handling.