What are the differences between AI and palletizing robot and handling robot

Our innovation and technology are developing more and more rapidly, so if we want to slow down the labor force of modern people and improve work efficiency, we will certainly use industrial robots to help us. The most common cases of robot industrial applications should be transportation and stacking. The difference between palletizing robot and handling robot is determined by his work content. In comparison, the palletizing robot is easier to control.

At present, our innovation and technology are developing more and more rapidly, so if we want to slow down the labor force of modern people and improve work efficiency, we will certainly use industrial robots to help us. The most common cases of robot industrial applications should be transportation and stacking. The difference between palletizing robot and handling robot is determined by his work content. In comparison, the palletizing robot is easier to control. The two industrial robots are combined from the hardware configuration, and the control mode is the same. Let's take a look.

What is the difference between palletizing robot and handling robot?

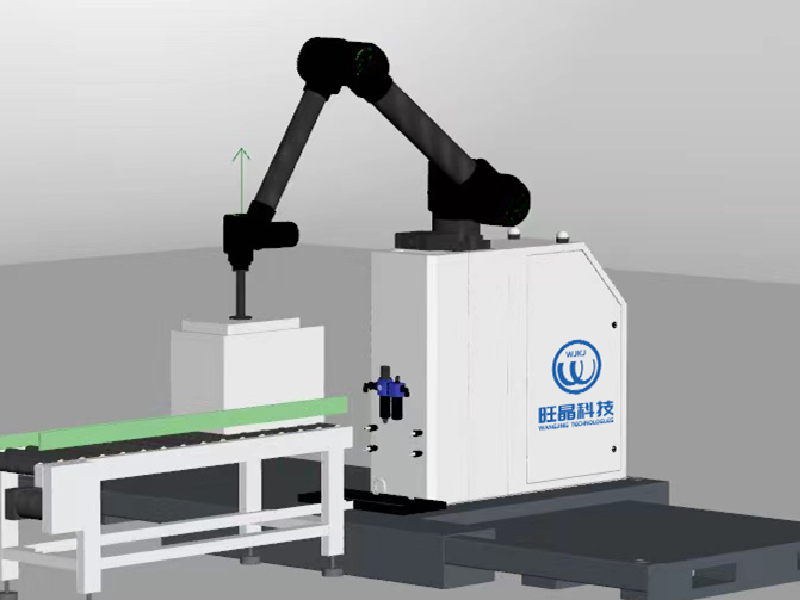

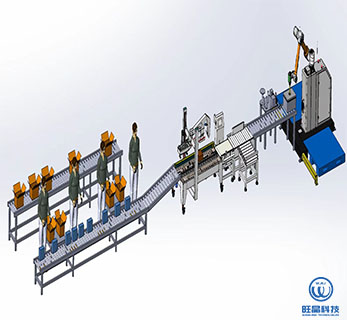

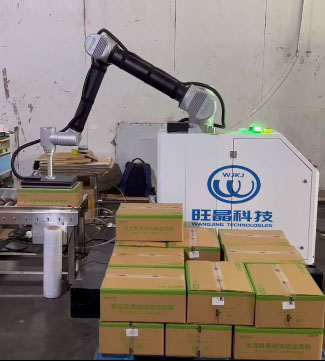

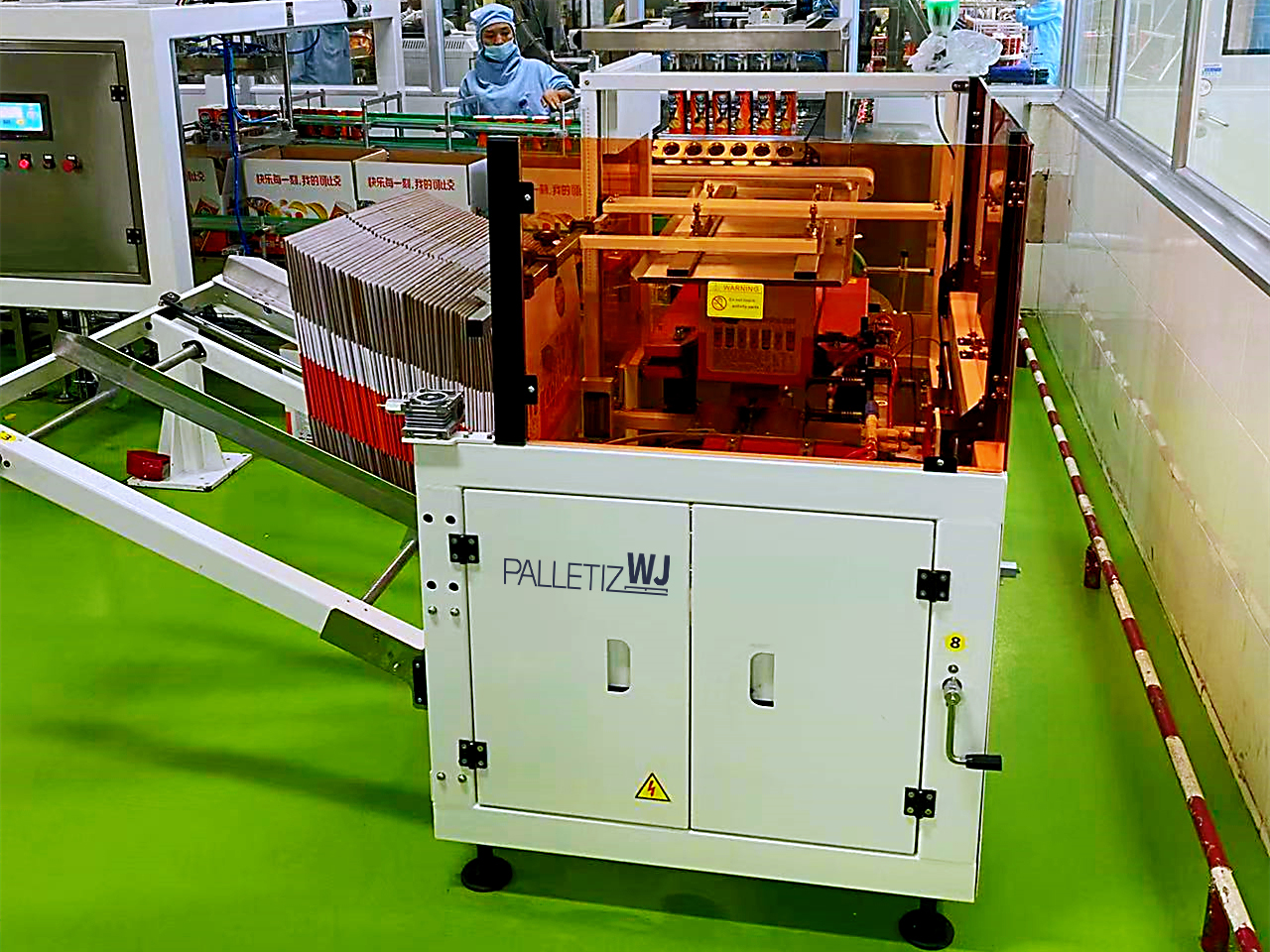

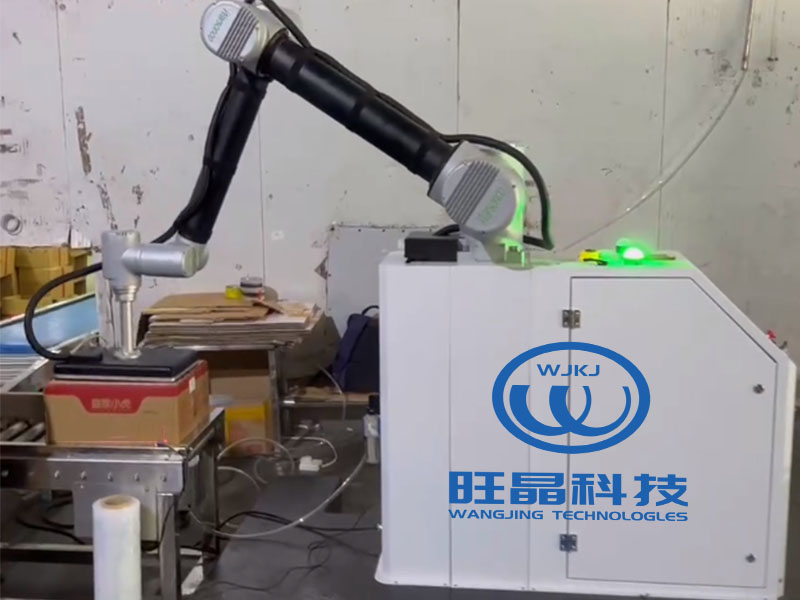

Stacking robot is an industrial development robot engaged in stacking. The articles loaded into containers are stacked on the company pallet and wooden pallet (wood, plastic) to a certain extent. Computer automatic stacking can be carried out by multi-layer stacking and then release, which is conducive to the application of forklift trucks to the warehouse for information storage. The palletizing robot can be integrated in any production line to provide intelligent systems, automation technology and digitalization for the production site, and realize various safe palletizing logistics for beer, beverage and food enterprises. It is widely used in carton, plastic box, bottle, bag, barrel, packaging bag and filling line products.

The handling robot is an industrial development robot, which can carry out management automation technology to transport safely. Operating industrial robots can install and use different end effectors. The porters have pictures of shapes and states, which greatly reduces the complex physical work of people. Its characteristic is that it can complete various prediction tasks by learning programming at the same time, and bring people and equipment development advantages in its own industrial structure and characteristics, especially reflecting the importance of AI technology and adaptability.