In this process, we should not only consider the characteristics of the automated production line, b

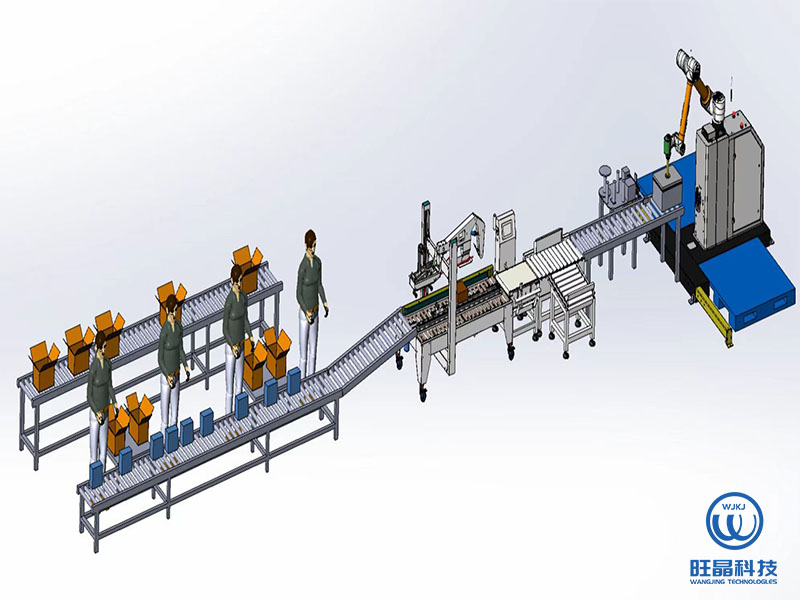

Automatic production line refers to the production line that connects the machines on the production line according to the technological process to realize automatic control, automatic measurement and automatic continuous production, including the whole process of feeding, discharging, loading and unloading and product processing. Automatic production lines are widely used in production enterprises, which can greatly improve the production efficiency of enterprises. Automatic production lines are more suitable for single products, and frequent replacement of production lines is a waste of production efficiency.

1. Produce fixed production lines or multiple products (components) on automated production lines, with fast and continuous production processes.

2. Each station on the automated production line is arranged in the order of the product process. Each station is only fixed with one or several processes, which is highly specialized and can improve production efficiency.

3. The automatic production line produces according to the standard rhythm (the so-called rhythm refers to the time interval between two production lines of the same product). Automatic production line is controlled by computer, with accurate calculation and no product accumulation.

4. The production capacity of each station on the automated production line is balanced in proportion, and the processing time of each process is equal to the beat or multiple of the beat, to reflect the production efficiency of the automated production line.

5. The automatic production line is equipped with special conveying device, and the product moves along the one-way conveying route.

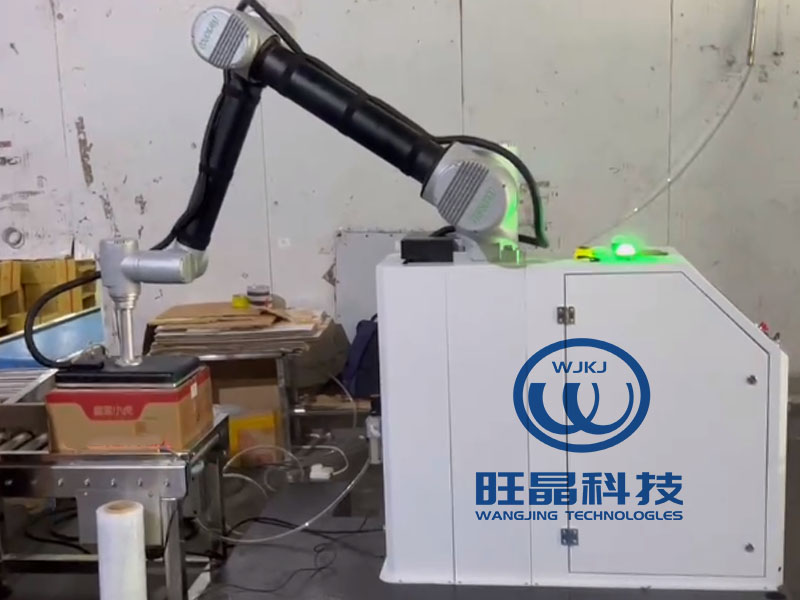

Automatic production line is to conduct automatic operation or control according to specified procedures or instructions under the condition of manual intervention, with the goal of "stability, accuracy and speed".

The use of automatic production lines can not only liberate people from heavy physical labor, part of mental labor and harsh and dangerous working environment, but also expand the functions of human organs, greatly improve labor productivity, and enhance human ability to understand and transform the world.