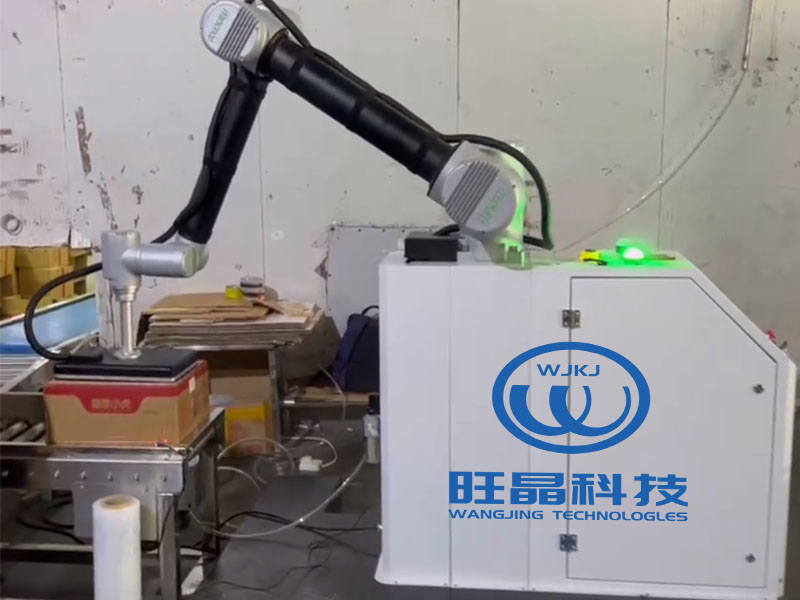

Our palletizing robot has many advantages

The operation of the palletizing robot is very simple, just set the picking position and tray position, and then design the running track to place the operation robot. The stacking position adjustment is also very simple, and can be directly operated on the touch screen. If you want to change another product, just input the specifications of the new product into the system.

Today's palletizing robots are different from traditional palletizers. The current palletizing robot is more intelligent, humanized and efficient than previous products. With the progress of the times and the continuous development of the economy, mechanical products are also constantly updated. Robots are also new products of our time. Stacking robot is a high-tech product of mechatronics. According to the grouping method and number of layers required, the stacking form of bags, plastic blocks, boxes and other products can be completed, which can make the stacking shape more compact and orderly. Therefore, palletizing robot has been widely used.

The palletizing robot can complete three-dimensional space transfer actions such as grabbing, carrying, turning, docking, and angle fine-tuning, providing an ideal handling and assembly tool for online material handling and assembly of production parts. The stacking manipulator reduces the labor intensity and provides safe material handling. At the same time, it can also provide system solutions for special environments such as explosion-proof workshops and dangerous places where personnel cannot enter. Through various non-standard fixtures, the manipulator can lift workpieces of various shapes to make the load reach the floating state of zero gravity. The operator can easily lift the load, move, rotate, tilt forward, and turn over. And quickly and accurately put the load to the preset position, so that one person can use it to operate items that originally required several people to move.