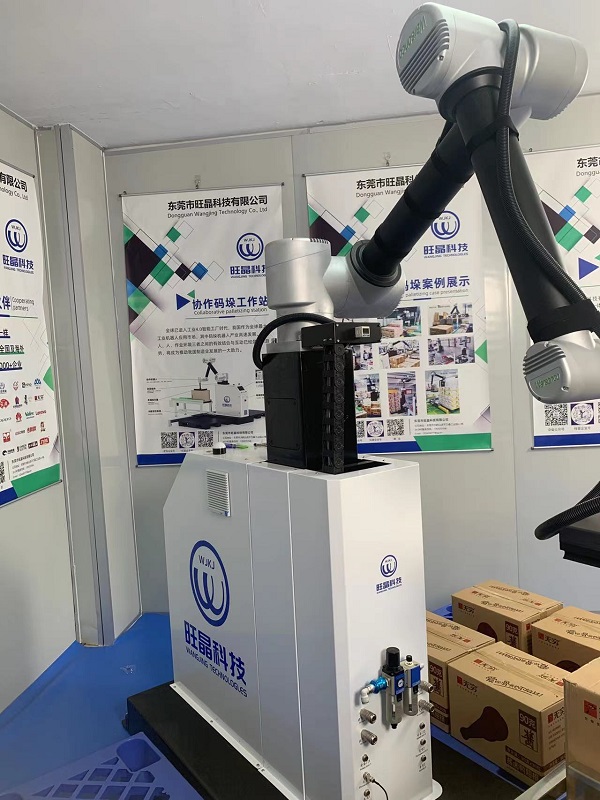

Robot is one of the important characteristics of palletizing robot in intelligent manufacturing

Stacking robot Mechatronic high-tech products can complete the high automation of the system and provide necessary maintenance for equipment and operators.Although the price is higher than the ordinary stacker, its future application value is far beyond your imagination. The success of the palletizing robot can be attributed to the following five characteristics:

1. Low energy consumption. Generally, the power of mechanical stacker is about 26KW, and that of stacking robot is about 5KW. Greatly reduce the operating costs of customers;

2. Simple structure and few parts. Therefore, the failure rate of parts is low, the function is reliable, the maintenance is simple, and the inventory parts required are few;

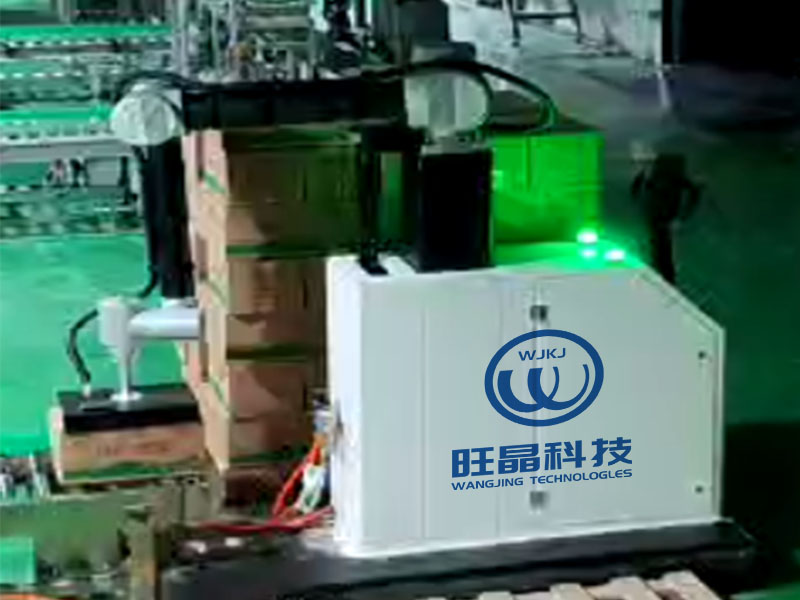

3. Strong applicability. When the size, volume, shape of the customer's goods and the overall dimensions of the pallet change, minor corrections can be made on the touch screen without affecting the normal production of the customer. The mechanical stacker can not be properly replaced even though it takes a lot of effort.

4. All controls can be operated on the screen of the control cabinet, which is very simple;

5. Small floor area. This helps to place the production line in the customer's factory and allows for a larger warehouse area. The palletizing robot can be installed in a narrow space and can be used effectively.

No matter which of these five characteristics is related to the stacking robot, it cannot be ignored. Because the palletizing robot is a collection of these advantages, it is these advantages that have contributed to its achievements today.