We are now studying the problems faced by palletizing robots

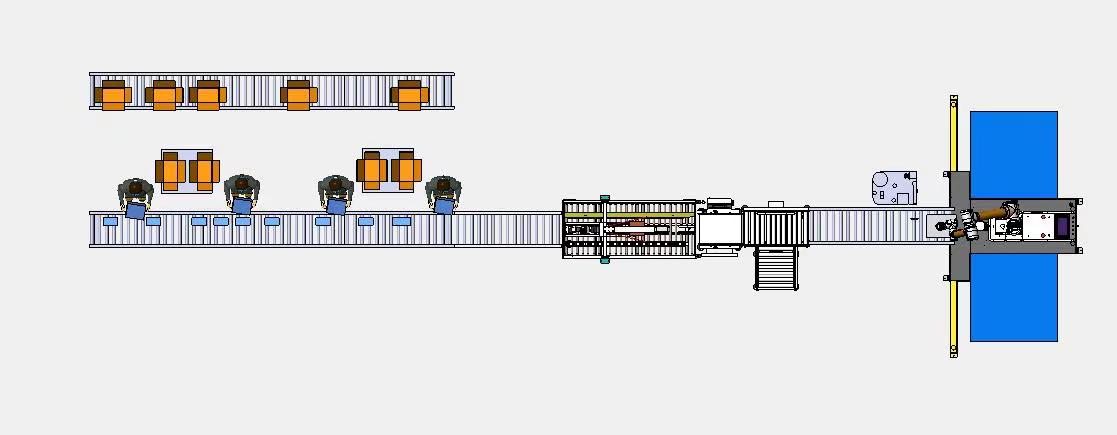

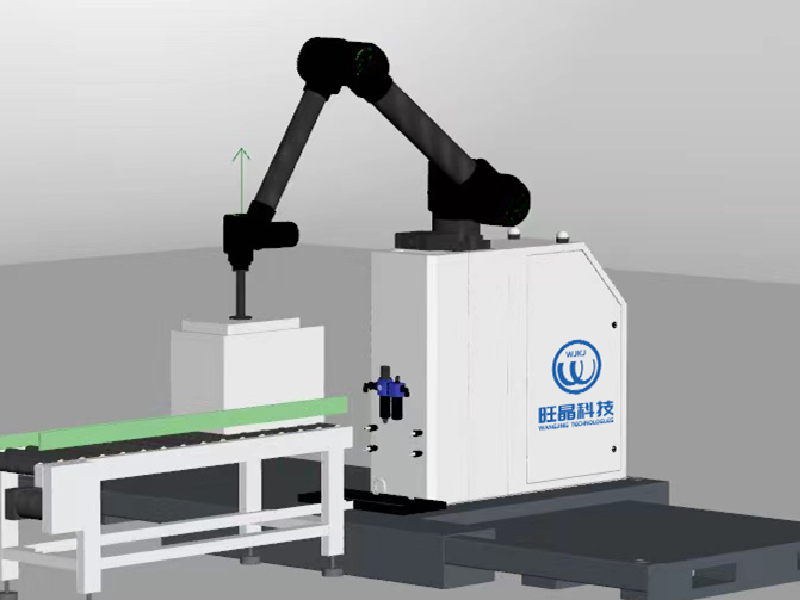

Stacking robot is a kind of industrial robot, which is widely used at present. With the decline of labor rate and the rise of labor cost, palletizing robots are used more and more. Stackers and porters are manufactured in manufacturing enterprises to replace manual post packaging operations.

It can improve product quality and output, and reduce labor costs. The stacking robot has a simple and durable structure. It can work with high intensity for a long time in various environments, reduce the occurrence of industrial accidents, and integrate into various production lines. The palletizing robot has many advantages, so what are the problems it faces?

1. High cost and many varieties.

The design and manufacture of palletizing robot is a systematic project, which is time-consuming and labor-intensive. There are various operating environments and objects, as well as various user requirements. Moreover, the variety and specification are not conducive to the batch and standardization of enterprises, and the cost cannot be reduced.

2. Adaptability needs to be improved.

Modern industrial production is characterized by small batch, multiple varieties, rapid upgrading and fine division of labor. The robot stacker must face the situation of one machine with multiple products, one machine with multiple pallets and one machine with multiple lines. The dimension parameters and stacking mode of product packaging are pre programmed and input into the robot stacker. The robot itself cannot recognize objects. Once the products are frequently replaced, the robot cannot quickly recognize them.

3. The research and development of heavy-duty stacking robot needs to be improved.

At present, most palletizing robots on the market are medium-sized, and there are also small parallel bars robots. The bigger one is about 3m high, and the smaller one is more than 1m high. The palletizing robot for grabbing large items such as plates still needs to be developed and produced, and the robot with large load is generally less than 200kg, which needs to be improved.

4. There is a shortage of talents. Stacking robots adapt to the development of the times and have broad industrial prospects.

However, the imbalance between supply and demand of talents in this field has become increasingly prominent. In the future, the development of robot industry will show an explosive trend, and the technical level will be greatly improved. Therefore, the technical level of robot operators may need to be improved, but there are few relevant talents. In order to reduce the cost of learning and training related talents, the problems of universality and usability of robots have emerged.