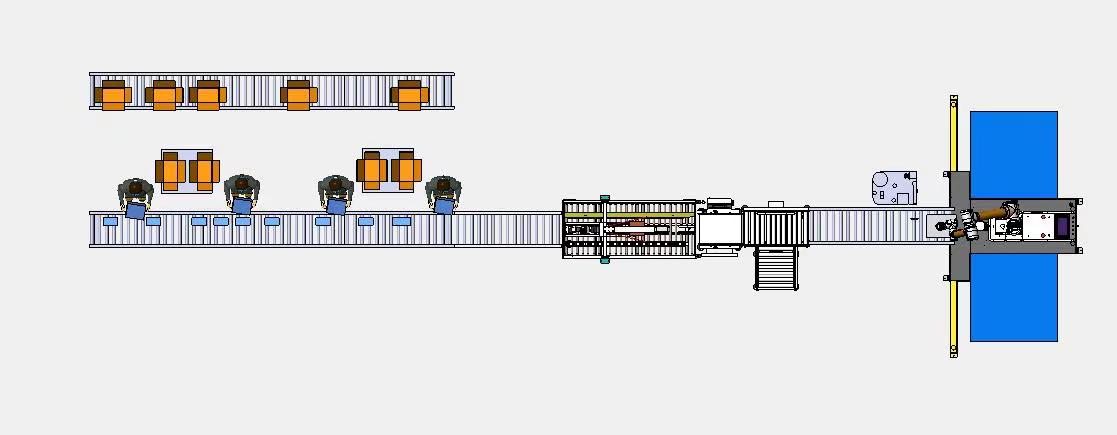

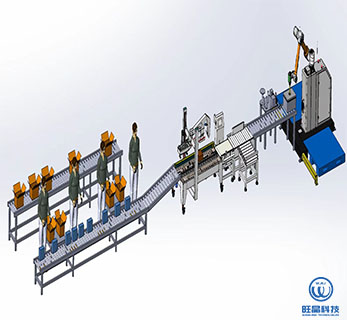

Cooperative dynamic stacker plays an important role in enterprise production

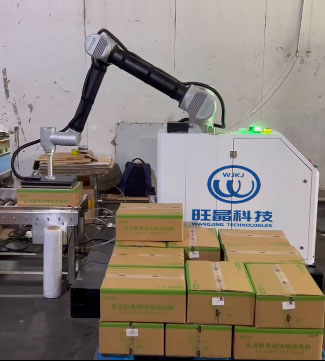

Now it is difficult for manufacturing enterprises to recruit workers, and manual handling and palletizing can no longer meet the production needs of enterprises. Stackers are widely used in packaging machinery industry. Cooperative stacker has the advantages of simple structure, small volume, light weight, fast speed, safety, energy saving, beautiful appearance, etc. The power of the whole machine is smaller than that of the traditional stacker, which can save a lot of electric energy every year. And it can greatly shorten the length of the production line, reduce the number of equipment, and simplify the process. The robot can unload and stack nylon (paper) bags, cartons, plastic boxes and woven bags through configuration.

Advantages of cooperative stacker

1. Automation: the bag is pushed from the bag pusher to the delaminator. After reclassifying at the top, the laminator is opened and placed on the lift tray.

2. High production capacity: compared with manual stacking, automatic stacking machine has the advantage of continuous operation.

3. Adjustable speed: the automatic stacker can stack at the set speed as required.

4. Safety: The use of automatic stacker can avoid the occupational injury that may be caused to workers during the work process, and reduce the management cost and risk of the enterprise.

5. Low cost: under the premise of large quantities and long construction period, the total cost of using automatic palletizer is lower than the input of labor cost.