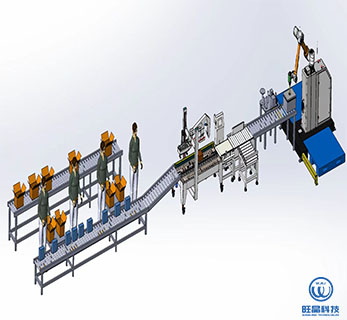

This is the use method of a fully automatic stacker

Now, more and more enterprises use automatic stackers. It is worth noting that there are many skills to understand and master in the process of using automatic stackers.

In order to better let enterprise customers know more about the operation and use of automatic stackers, the following details about the operation and use of automatic stackers mainly include the following aspects:

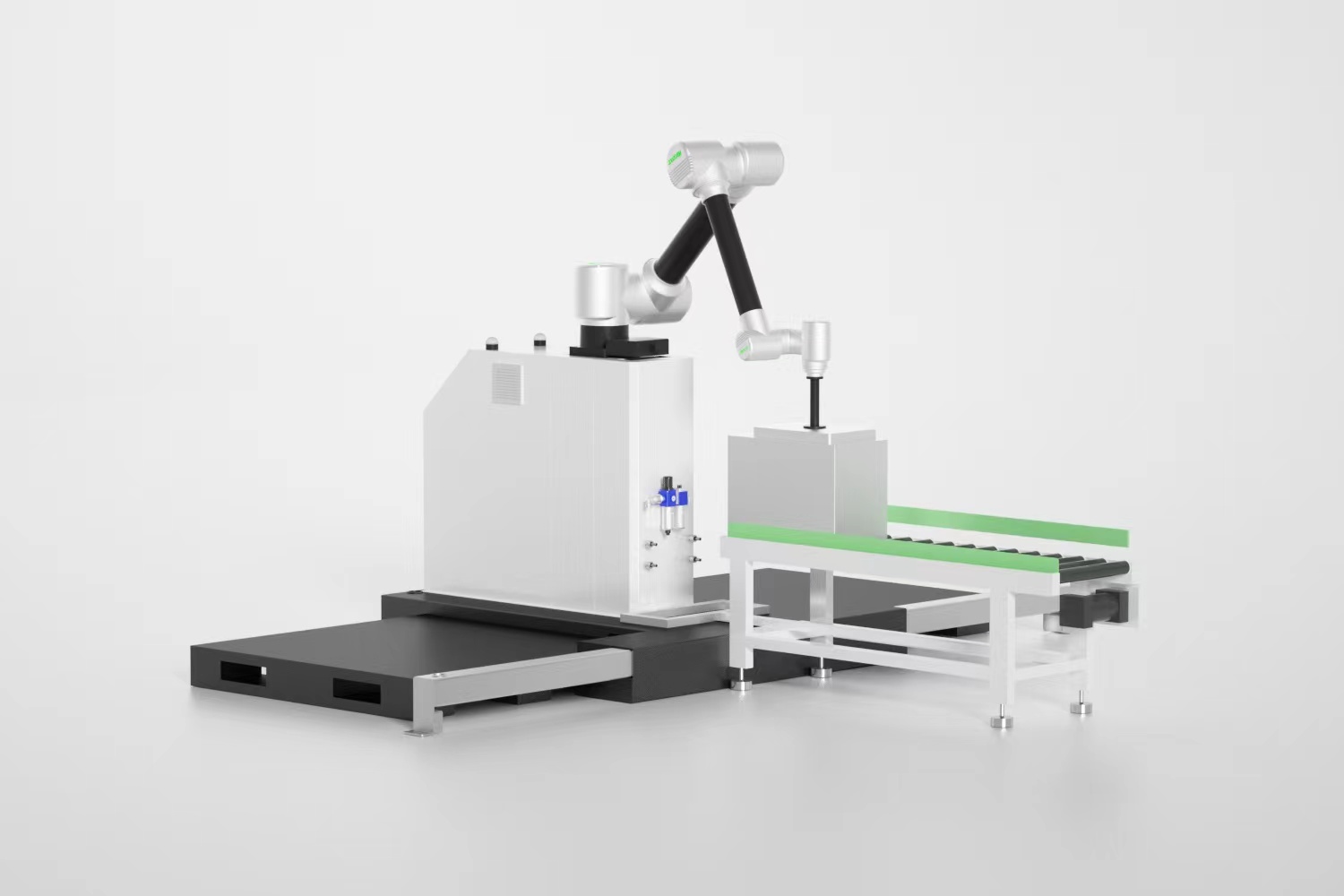

When installing the automatic stacker, ask professional personnel to install it. If any problems occur during installation, please contact the vender of the automatic stacker immediately. Do not install the faulty parts on the machine. This will increase the pressure on other parts and increase the possibility of failure of the automatic stacker. Secondly, it is necessary to ensure that all lines of the automatic stacker are connected correctly, so that it can be used more stably, without short circuit or electric shock.

Before using the automatic stacker each time, check all facilities of the robot stacker to see if there is any problem. If there is any problem, solve it as soon as possible before starting. When operating the automatic stacker, do not operate the machine with wet hands to avoid problems. If the parts of the robot stacker in use have problems, the power supply shall be cut off in time, the system shall be shut down, and measures shall be taken to repair the machine or replace the spare parts.

The fully automatic stacker can only be used correctly according to the operating system manual and instructions under the appropriate technical development conditions, and checked and maintained according to the relevant specified time. During the operation of the automatic stacker, the management personnel shall be familiar with the hazards that may be encountered during the operation of the equipment and strictly abide by the operating procedures.

The operation of different brands and models of the automatic stacker may be different, so when using the equipment, you should carefully read the manual of the automatic stacker and operate according to the instructions of the equipment to avoid damage to the automatic stacker due to your wrong operation.