Stacker realizes unmanned factory landing in food industry

Industrial robots are the main force for "unmanned factory" to achieve production development, and also the key point for intelligent upgrading of manufacturing enterprises. It is based on artificial intelligence, computer control technology and other execution work. It can replace manual work in industrial production to complete some frequent, repeated and dangerous long-term operations. It has universality and adaptability, and can effectively improve work efficiency and production standards. It has been widely used in all walks of life.

For the food industry, intelligent technology also has a great impact on the industry. The production intelligence brought by equipment automation has become one of the competitiveness of food production enterprises. Among them, the packaging and palletizing robot, which is widely used in the food industry, has a simple structure. It can complete many operations such as grasping, handling, loading and unloading, and stacking by relying on the robot system. It has the characteristics of low power consumption, high reliability, and high efficiency, and is favored by many enterprises in the food industry.

It will be held from August 24 to 26. At the 2022 Global High end Food Expo, supported by China Non staple Food Circulation Association and hosted by Beijing Longpinxi Exhibition Co., Ltd., the robot stacker developed by Dongguan Wangjing Technology Co., Ltd. will help the rear end of the production line realize automatic packaging and stacking, and help many food enterprises participating in the exhibition to realize the landing of unmanned factories.

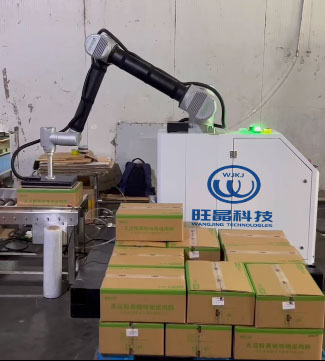

Dongguan Wangjing Technology Co., Ltd. is a scientific and technological enterprise focusing on industrial robots from production research and development to manufacturing and sales. It is a leader in the field of automatic robots. In the industrial robot market that Baifang is competing for, the WJKJ-MD collaborative palletizing robot, which is developed by Wangjing Technology in the lead, has broken through the tight encirclement. Compared with the conventional industrial palletizing robot with a high penetration rate in the market, the WJKJ-MD collaborative palletizing robot performs better in industrial action, and is a popular choice for factory procurement at present.

This palletizing robot is extremely suitable for assembly line operation. In the workflow, as long as the pallet is manually placed at the designated position, it will be left for palletizing. After that, WJKJ-MD palletizing robot will wave its special fixture to grab the product and place it on the pallet according to the preset placement mode. The whole process requires no manpower. It is suitable for the production line with relatively slow speed. With simple operation and stable action, it can greatly reduce labor force and labor intensity.

It is reported that the 2022 Global High end Food Expo will cover an exhibition area of 100000 square meters, gather more than 1500 exhibitors, and have special sections for imported food, trendy food, leisure food, ice cream frozen food, prepared dishes, fresh food materials, drinks, etc. It is estimated that the professional audience will reach 120000 person times, which will be a whole food exhibition event with larger scale, more complete products and more audiences in history. Among them, many well-known enterprises in the exhibition realized the landing of unmanned factories by using the palletizing robots launched by Dongguan Wangjing Technology Co., Ltd.

In the future, Dongguan Wangjing Technology Co., Ltd. will continue to improve its R&D and manufacturing technology, save labor costs for more and more food enterprises, improve production efficiency, and realize the implementation of unmanned factories.