With the development of artificial intelligence technology, the role of unmanned cooperative stackin

The role of robots in industry has replaced human workers in many manufacturing industries. Machines like mechanical arms make it possible for humans to perform tasks with brute force before automation. Now they have replaced heavy lifting and precision assembly. The use of industrial robots can not only help create products, but also reduce waste and improve safety.

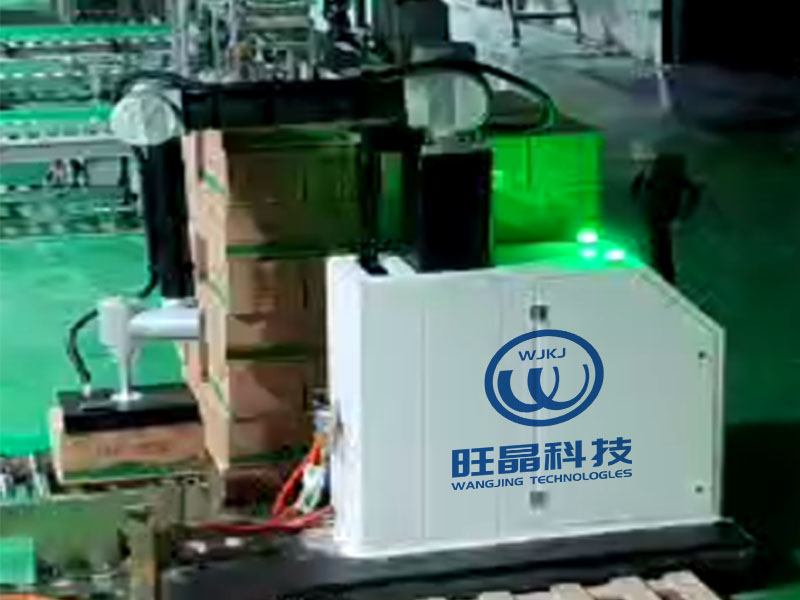

Today's factories produce millions of products simultaneously. To keep pace, robotics has improved to the point where production lines now move at 20 miles per hour. The cooperative palletizing robot can also combine the conveyor belt with the forklift, so the operator no longer needs to lift and lower the load independently. These machines enable manufacturers to maximize efficiency and save on the cost of transporting materials in the factory. Today we see a large number of automated machines. They appear in different forms depending on the purpose of the service. Many manufacturing industries now rely heavily on machines. Automating the production process with robotic tools can help reduce labor requirements and significantly improve productivity. Robots play an important role in almost all manufacturing industries.

From carrying goods to packaging to assembly and testing, robots are increasingly replacing humans to perform repetitive tasks in manufacturing. Stacking can reduce inventory and unnecessary storage space, so that enterprises can greatly reduce transportation costs, thereby increasing profits. At present, some heavy equipment (such as forklifts) requires manual lifting by workers, rather than loading goods onto pallets. This limits productivity and increases the risk of accidents. Automated Palletizing Robot (APR) reduces the labor required on pallets by providing an automated platform to lift and place goods accurately. This reduces the risk of accidents associated with manual handling operations. When there is too much debt, it is more difficult for the enterprise to generate the cash flow needed to repay the loan.

Robots automate warehouse operations, eliminating the need for labor. The warehouse keeper supervises the robot system because each robot performs a specific task according to the instructions provided by the human supervisor. Help automation managers save a lot of cash, thereby reducing overall production costs. By automating the warehouse, humans can free up time to perform other tasks, thus achieving faster turnaround times, rather than manually processing products throughout the manufacturing phase. After weighing all the arguments, it is clear that APR system can help enterprises get rid of excess inventory and improve efficiency by reducing the costs related to managing human resources. In addition, cooperation with palletizing robots can reduce transportation costs and help enterprises save money.