How to realize the role of this technology in automated production lines?

With the development of automation technology, people pay more and more attention to the automatic and efficient production mode.

The emergence of automatic production line just meets the needs of industry development and solves the problem of production efficiency. Automatic production line plays an important role in industrial production, and I believe it will be more long-term in the future development process.

automatic production line? Let's take a look at the following functions:

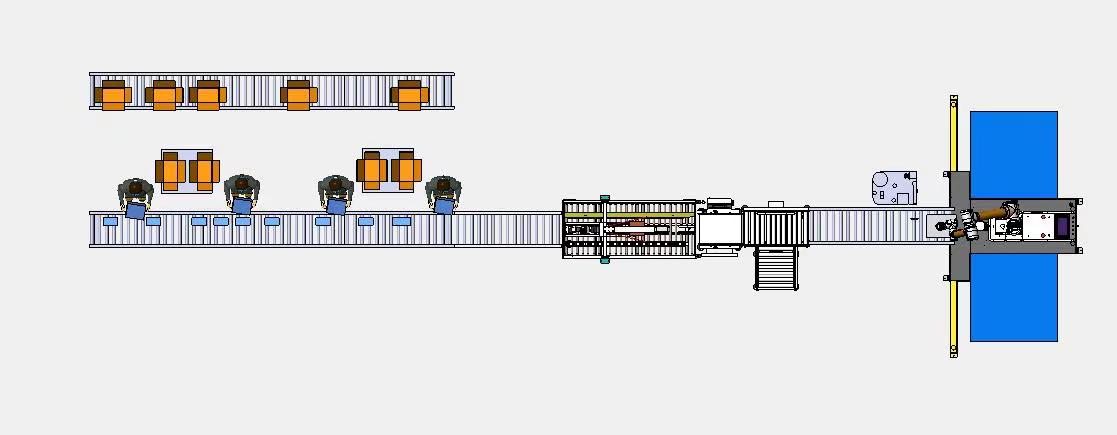

1. The automatic production line can be stable, with less labor and high production efficiency. The manufacturing cost of a single product is greatly reduced, and the space occupied is minimal.

2. Products with high degree of standardization, large output and many processes are more suitable for automated production lines.

3. Automatic production lines can greatly improve the production efficiency of enterprises and obtain greater benefits. It is applicable to products with mature product design, huge market demand, many assembly processes and long production cycle.

4. The use of automatic production lines can improve labor productivity, reduce production costs, shorten production cycle and ensure production balance.

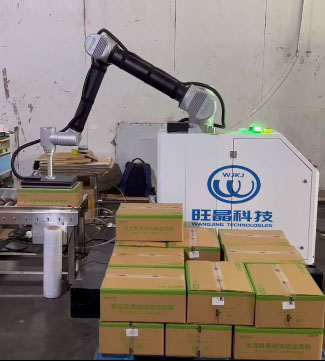

With the development of industrial robots, electronic computers and other technologies, the application flexibility is growing, which can realize the automation of multi variety, small and medium-sized batch production. Therefore, the application of automatic production line in mechanical manufacturing industry is more and more extensive, and it is developing towards a more automated flexible manufacturing system.