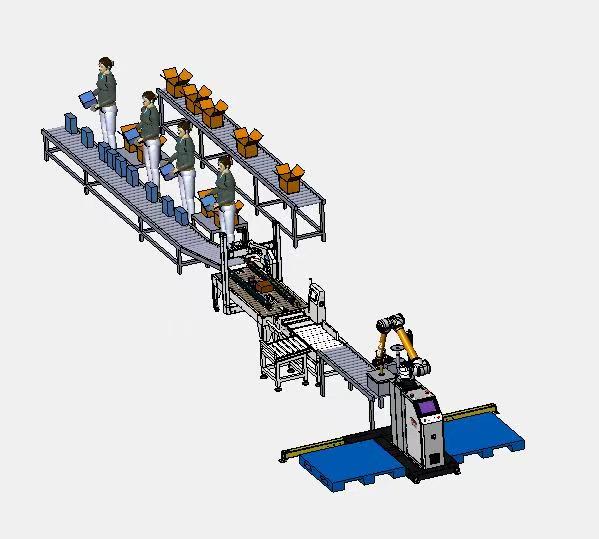

At present, the company has formed a whole industrial chain automatic production line process layout

The advantages of the automatic production line are very obvious, but if the overall planning of the initial overall processing process layout is not good, the advantages of the automatic production line will be discounted. The automatic production line process layout is generally divided into linear layout, zigzag layout, and T-shaped layout

Market outlook 2022-11-03

Comparison between mobile cooperative palletizing robot and industrial palletizing robot

With the development of urbanization and the gradual promotion of industrial production reform and innovation, automatic machinery has become the main power for today's industrial development. The productivity of social development has also ushered in a new peak in the mechanical automation reform in which cooperative palletizing robots replace human resources. Nowadays, there are various types of industrial manipulators. How to choose in the sinking market?

Market outlook 2022-09-20

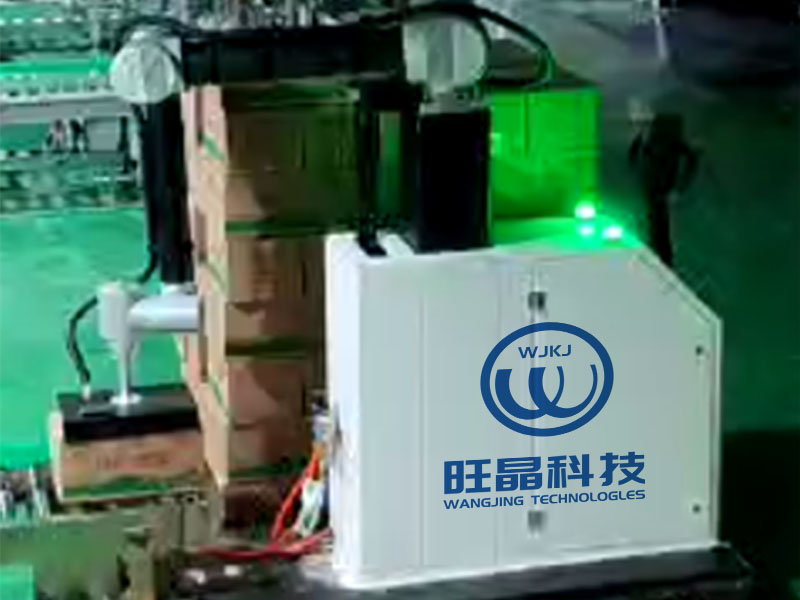

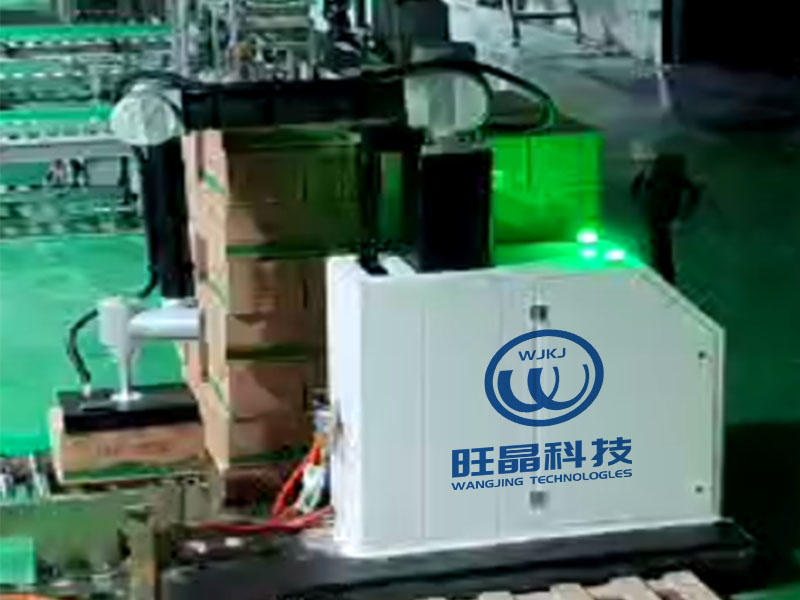

This technology is fully automatic palletizer, which is a good helper for enterprise production

Many people have only a general understanding of stackers. They believe that the stacker is a simple mechanical equipment used for handling and stacking goods. In fact, the stacker is not just a simple mechanical equipment. Many production workshops have palletizing robots to load, unload and stack goods. The use of palletizing robots is several times more efficient than traditional labor, but it can also reduce the human cost of enterprises.

Market outlook 2022-09-23

With the development of automatic stackers, automatic stackers are used more and more widely, and mo

The labor intensity of manual stacking is high, and the turnover rate of post labor is high, which has a serious impact on production management. With the development of science and technology, the appearance of automatic stacker saves time and energy for product stacking, and can better help enterprises to complete transportation tasks.

Market outlook 2022-09-29

This is the important significance of our country to the automatic stacker

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

Market outlook 2022-09-28

Market pattern analysis, artificial intelligence technology development and application of cooperati

Cooperative robot is an important branch of industrial robot. The cooperative robot is mainly lightweight, and its structure is relatively simple, so the whole robot lacks rigidity. Therefore, the load of cooperative robot is generally lower than that of traditional industrial robot, and its working range is only similar to that of human arm. The application of cooperative robot products meets the requirements of precision assembly, inspection and man-machine joint operation.

Market outlook 2022-10-07

How to optimize the workflow and how to use these cooperative mobile palletizing robots

Collaboration brings into full play the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads

Market outlook 2022-10-12

What are the benefits of using the fully automatic stacker

With the emergence of automatic stackers, stackers are more and more widely used in our lives. Do you know the advantages of using automatic stackers?

Market outlook 2022-09-29