This is the important significance of our country to the automatic stacker

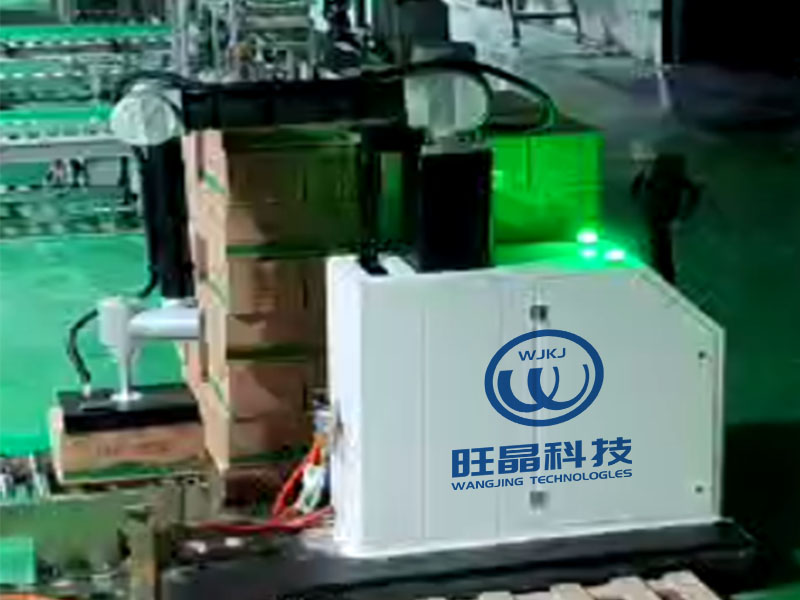

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

Market outlook 2022-09-28

With the rapid development of intelligent manufacturing, palletizing robot has become the mainstream

With the increasing popularity of automatic robot production, the cost of robots is also decreasing. In the past 30 years, the average price of robots has actually dropped by half, even exceeding the labor cost.

Market outlook 2022-10-06

In the field of industrial robots, what are the application scenarios of intelligent manufacturing a

The important role of cooperative palletizing robot is to reduce the cost of manual logistics and facilitate the grabbing, handling and placing of goods.

People often find them in various express collection points, factories and other industrial scenes.

In recent years, with the cooperative mobile palletizing robot system becoming more efficient, fast and accurate software, cooperative mobile palletizing robot has been gradually applied in many companies.

Market outlook 2022-10-31

Through robot palletizing, workers can achieve accurate control of robot palletizer gripper

The gripper of cooperative palletizing robot, also known as end effector, clamp and mechanical gripper, is an important part of the palletizing robot. The design of robot intelligent gripper generally uses image system to identify the size of the workpiece, and servo motor to adjust the spacing of the clamping plates.

Market outlook 2022-10-11

What is the working principle of palletizing robot

In our daily life, we often see or use palletizing robots. Just like when we go to the supermarket, many goods have to be put in high places. Some are manual and some are automatic. If manual operation is used, it is generally used in some small supermarkets, large malls, etc. However, in some large shopping malls or warehouses, it is not realistic to change the labor force. At this time, we need to set some programs to let the palletizing robot put in a specific position according to the set program.

Market outlook 2022-11-03

What is the basis for the normal and stable operation of our automatic stacker

Collaborative mobile has fully played the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads.

Market outlook 2022-10-27

This is the use method of a fully automatic stacker

Now, more and more enterprises use automatic stackers. It is worth noting that there are many skills to understand and master in the process of using automatic stackers.

Market outlook 2022-09-28

Now we have begun to study the application of knowledge of cooperative palletizing robot

Palletizing robot, also known as robot palletizing, is used for palletizing instead of manual operation, which can greatly improve work efficiency. In addition, the robot stacker can run for a long time, reducing the labor cost. Working principle of the stacker: place a layer of workpieces that meet the pallet requirements on the flat plate. And the flat piece moves forward to the vertical plane of the pallet. The upper stop rod drops, another tee positioning stop rod begins to clamp, and then the sheet is reset. Each workpiece shall be lowered to the pallet plane, the distance between the pallet plane and the bottom of the plate shall be 10mm, and the pallet shall be lowered by one workpiece height. Repeat the above steps until the pallet stacking meets the setting requirements.

Market outlook 2022-10-06