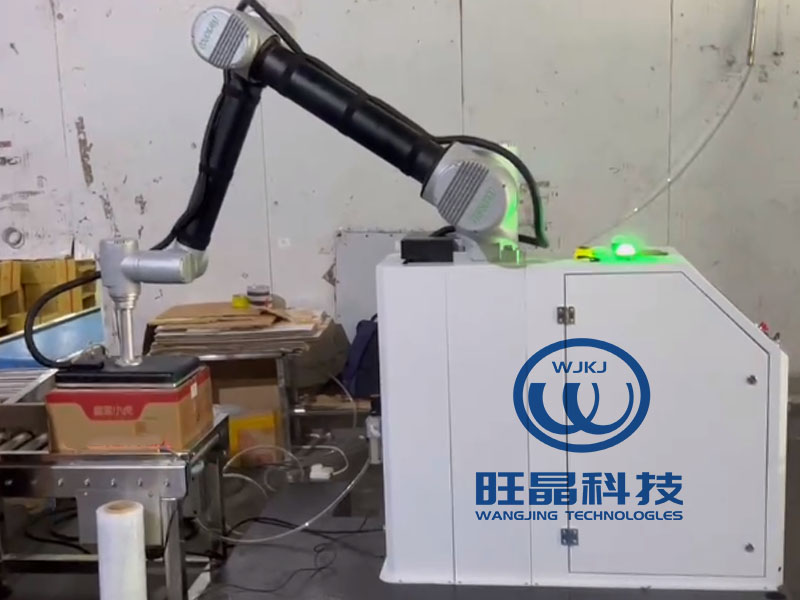

Now we have begun to study the application of knowledge of cooperative palletizing robot

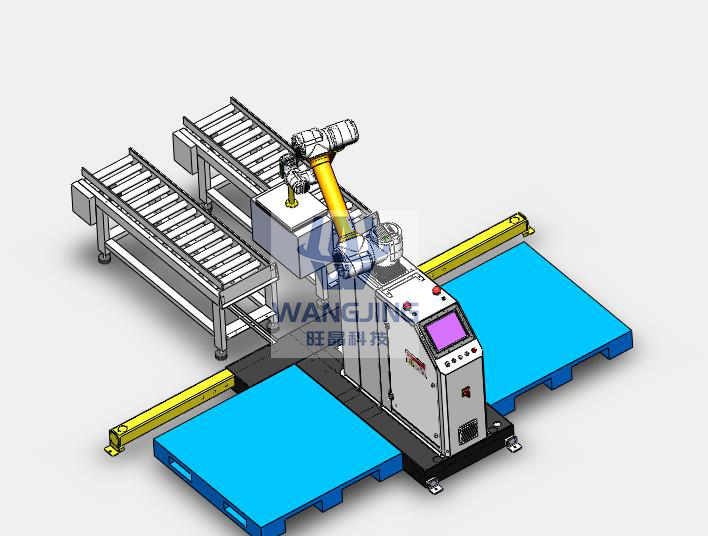

Palletizing robot, also known as robot palletizing, is used for palletizing instead of manual operation, which can greatly improve work efficiency. In addition, the robot stacker can run for a long time, reducing the labor cost. Working principle of the stacker: place a layer of workpieces that meet the pallet requirements on the flat plate. And the flat piece moves forward to the vertical plane of the pallet. The upper stop rod drops, another tee positioning stop rod begins to clamp, and then the sheet is reset. Each workpiece shall be lowered to the pallet plane, the distance between the pallet plane and the bottom of the plate shall be 10mm, and the pallet shall be lowered by one workpiece height. Repeat the above steps until the pallet stacking meets the setting requirements.

The main control elements of the cooperative stacker include programmable controller, frequency converter, proximity switch, button switch, wiring terminal, etc. All adopt first-class products to ensure the reliability and long life of the system hardware. The combination of high-quality hardware and special control software designed by experts realizes the high automation of the system. Perfect safety interlocking mechanism can provide protection for equipment and operators. The graphic display touch screen makes the stacker easy to operate, diagnose faults, repair and maintain.

Main features of the stacker: 1. High production efficiency: the best module configuration can be carried out according to the requirements and kiln conditions, and the maximum number of bricks can be customized. 2. Convenient garbage disposal: the belt conveyor is equipped with an automatic waste discharge system, and the surplus materials of the sludge belt can automatically leave the belt conveyor and return to the material return system. 3. Strong adaptability: the stacked bricks can be properly adjusted according to the customized brick burning situation, so that the bricks have better quality and lower cost. 4. More safe: When the manipulator does not work, it is equipped with a mechanical lock. During operation, there are manipulator rotation warning lights, relevant warning areas and warning signs. During maintenance, there is a safety maintenance platform above the rack. 5. Wide scope of application: applicable to standard bricks, perforated bricks, block bricks and other brick types; Applicable to tunnel kilns of various specifications, with a width of 2.5m-3.0m; The standard stacking height is 13 layers (the required stacking layers can be designed according to the height of the kiln body).

Stacking mode of the stacker: When the stacker is running, the first step is to put the products on the pallet of the stacker. After placement, the stacker will automatically transfer the products on the pallet to the next equipment through the conveyor belt. After the stacked products are automatically put into the box, the next step is to transfer the box. After the transfer is completed, the items to be stacked are stacked according to the preset data, and then stacked according to the number of products and stacking layers. After piling up the pile, use the conveyor belt to move the pile to the next position for the next step.

The products are stacked in the cooperative palletizing robot, and the rest of the products need to be transferred from the automatic palletizer. Stacked products are transported to the stacking site by conveyor belt. After stacking, perform the stacking step. After this step is completed, the stacked products can be stacked down and taken out. These are the general steps of an automatic stacker. Some stackers have different models and specifications and different stacking steps.