This is the use method of a fully automatic stacker

Now, more and more enterprises use automatic stackers. It is worth noting that there are many skills to understand and master in the process of using automatic stackers.

Market outlook 2022-09-28

In this way, enterprises can benefit from using automatic palletizer.

Why do enterprises need to purchase automatic stackers? Is it simply because the equipment can be automated, making handling and palletizing easier?

Market outlook 2022-09-22

In this process, we should not only consider the characteristics of the automated production line, b

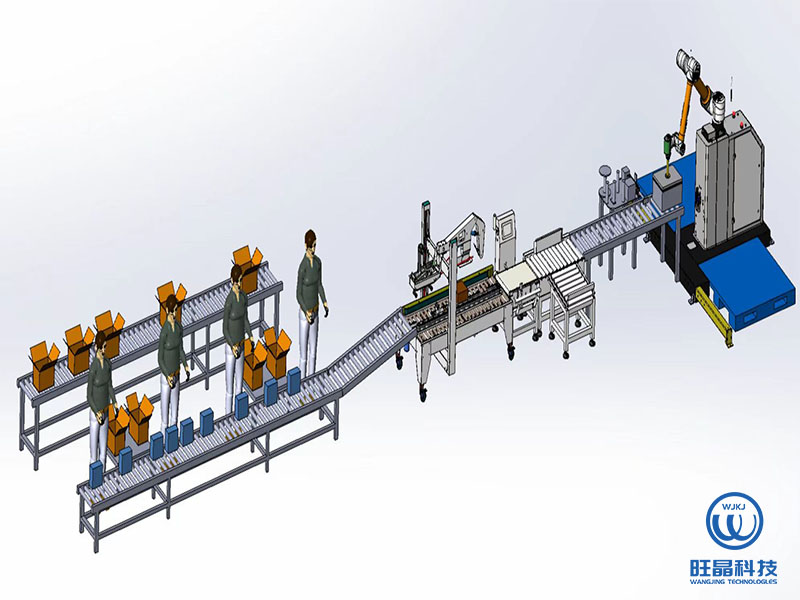

Automatic production line refers to the production line that connects the machines on the production line according to the technological process to realize automatic control, automatic measurement and automatic continuous production, including the whole p

Market outlook 2022-11-08

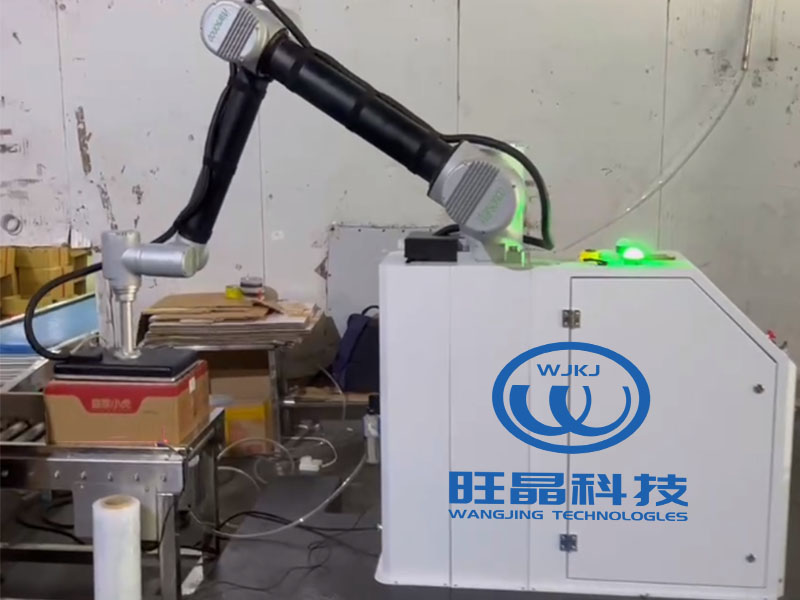

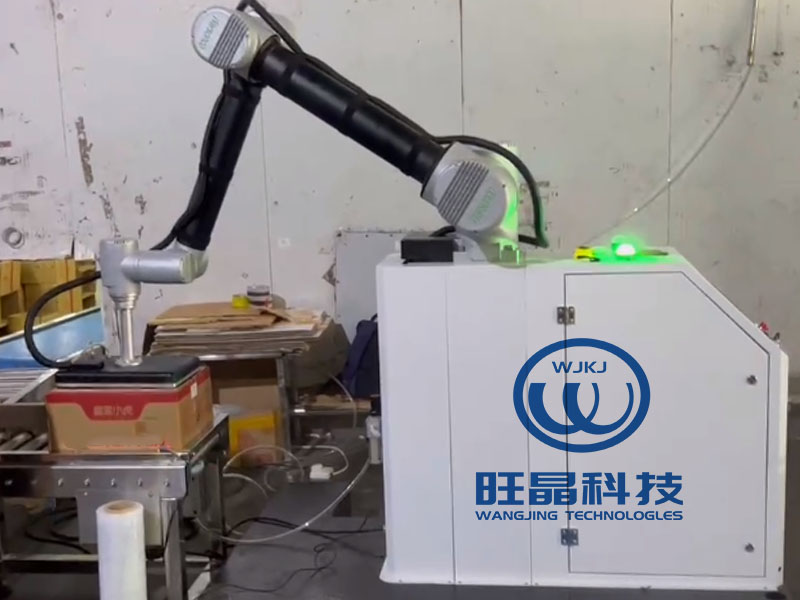

Main application industries of cooperative stacker

In recent years, with the rapid development of food, beverage and health care industries, the intensity of manual stacking is high, and the rate of staff turnover is high, which has seriously affected the production management of food, medicine and other industries. With the development of science and technology, the emergence of automatic palletizing machine saves the time of product palletizing and helps enterprises to complete the transportation task better. Now let's take a look at the main application fields of automatic stacker

Market outlook 2022-09-29

At present, what functions does the intelligent robot stacker have?

Robot palletizing opportunities greatly reduce human capital and labor efficiency. The stacker is used to automatically stack the packaging bags, cartons or other packaging products sent by the belt conveyor according to the working mode of the customer's process standards, and then transport the stacked raw materials to the designated location through the electric forklift mechanical equipment.

Market outlook 2022-10-27

As an industrial robot, palletizing robot is one of the key emerging industries for China to impleme

Cooperative palletizing robot, an industrial robot, is a key emerging industry in China's implementation of the manufacturing power strategy. The development level of robot industry is an important symbol to measure a country's innovation ability and industrial development level.

Market outlook 2022-09-21

What are the application fields of 3D cooperative destacking robot

Collaborative 3D destacking robot is widely used in logistics and warehousing, production and manufacturing, outer packaging, production and processing and other industrial production commodity circulation and freight logistics scenarios. Select the plan scheme of 3D camera+machine vision algorithm.

The 3D point cloud information of the object is obtained through the 3D camera, the part and specification of the object that must be unpacked are calculated using the visual algorithm, and the industrial robot is correctly guided to carry out the automatic operation of unpacking according to the control platform.

Market outlook 2022-09-18

This 3D destacking robot realizes hybrid destacking automation and can realize multiple processes

In recent years, a variety of warehouse automation machines and equipment have appeared in China. How to use automated machines to improve the efficiency of warehousing operations and reduce labor seems to be the concern of the warehousing industry at this stage. From process planning to software and hardware design, the specific conditions of the construction site should be fully considered. The invention can improve the limit under complex scenes and achieve efficient operation

Market outlook 2022-11-01