At present, what are the factors we need to consider in selecting industrial cooperative robots? How

For an old bird in the automation industry, a senior mechanic, and an electrician, selecting a suitable "robot" may be a simple task. But for those designers or factories who are ready to purchase and import robots for the first time, there may be some confusion.

The main factors to consider when selecting a cooperative robot are: the type, function, brand, price, performance and reliability of the cooperative robot. Enterprises should choose appropriate cooperative robots according to their own conditions. Based on the following nine professional parameters, this paper discusses how to select a suitable cooperative robot.

1. Application occasions

First, the most important source is to evaluate what applications and processes the imported robots are used for.

If the application process needs to be completed manually by the machine, Co robots should be a good choice for common semi-automatic lines with human-machine mix, especially in the case of frequent station changing or line shifting, and in the case of matching new torque sensors.

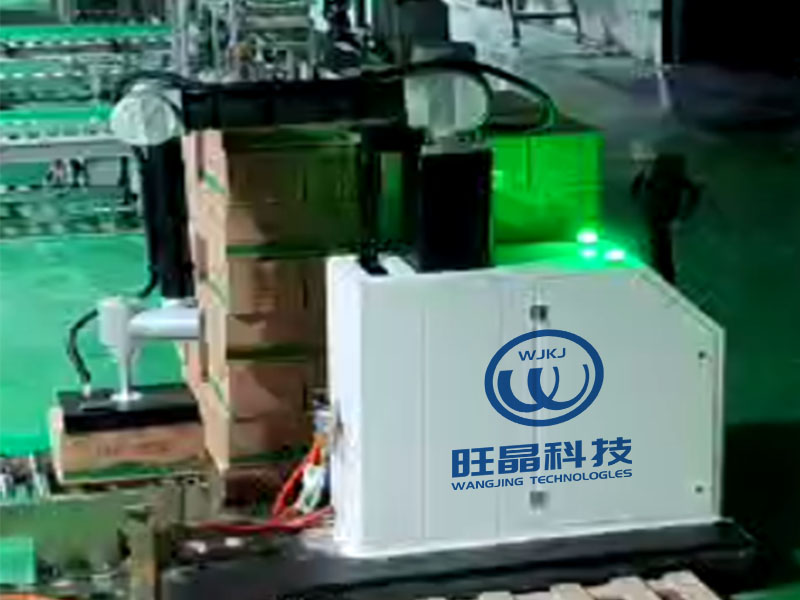

In the following discussion, we will focus on articulated multi axis robots. This kind of robot can adapt to a very wide range of applications. From taking to stacking, there are also special processes such as spraying, deburring and welding. Currently, cooperative robot manufacturers basically have corresponding robot solutions for each application process. All you have to do is know what you want robots to do for you, and choose the most appropriate model from different types.

2. Payload

Payload is the maximum load that a robot can carry in its workspace. For example, from 1.5 kg to 20 kg.

If you want the robot to move the target workpiece from one station to another, you need to add the weight of the workpiece and the weight of the robot gripper to its workload.

In addition, pay special attention to the load curve of the robot. The actual load capacity will be different at different distances in space.

3. Degrees of freedom (number of axes)

The number of axes configured by the robot is directly related to its degree of freedom. For simple and direct occasions, such as taking it from one belt line to another, a simple 4-axis robot is enough.

However, if the application scenario is in a narrow workspace and the mechanical arm needs a lot of twisting and rotation, a 6-axis or 7-axis robot will be the best choice.

The number of axes usually depends on the application. It should be noted that under the premise of cost permitting, it is not a problem to select more point axes in terms of flexibility. In this way, it is convenient to reuse the robot to another application process, which can adapt to more tasks rather than finding that the number of axes is insufficient.

Robot manufacturers tend to name their axes or joints with slightly different names. Basically, the first joint (J1) is the joint closest to the robot base. The following joints are called J2, JBOY3 band, J4, etc., until the end of the wrist.

4. Maximum actuation range

When evaluating the target application, you should know the maximum distance the robot needs to reach. The choice of robot is not only based on its payload - it also needs to consider the exact distance it reaches. Each company will give the corresponding robot's motion range diagram, from which it can judge whether the robot is suitable for a specific application. For the horizontal movement range of the robot, pay attention to a non working area near and behind the robot.

The measurement of the maximum vertical height of the robot is the distance (y) from the lowest point that the robot can reach (usually below the base of the robot) to the maximum height that the wrist can reach. The maximum horizontal actuation distance is the distance (x) from the center of the robot base to the center of the farthest point that the wrist can reach horizontally.

5. Repetition accuracy

Again, this factor depends on your application. Repetition accuracy can be described as the ability of a robot to complete routine tasks and reach the same position each time.

It is generally between 0.05mm and 0.02mm, even more accurate. For example, if you need your robot to assemble electronic circuit boards, you may need a robot with super precision and repeatability. If the application process is rough, such as packaging and palletizing. Cooperative robots do not need to be so precise.

On the other hand, the selection requirements for robot accuracy in assembly engineering are also related to the transfer and calculation of dimensions and tolerances in each link of assembly engineering, such as the positioning accuracy of incoming materials, the repetitive positioning accuracy of the workpiece itself in the fixture, etc. This index is expressed in positive and negative terms in 2D. In fact, since the motion repetition point of the robot is not linear, but moves in 3D space, the actual situation of this parameter can be any position in the spherical space within the tolerance radius.

Of course, the current motion compensation combined with the current machine vision technology will reduce the requirements and dependence of the robot on the incoming material accuracy and improve the overall assembly accuracy.

6. Speed

This parameter is closely related to each user. In fact, it depends on the cycle time that the work needs to be completed. The manual lists the maximum speed of this kind of robot, but it should be known that, considering the acceleration and deceleration from one point to another, the actual running speed will be between 0 and the maximum speed. The unit of this parameter is usually degrees per second. Some robot manufacturers also mark the maximum acceleration of the robot.

7. Body weight

The weight of robot is an important factor in the design of robot unit. If the cooperative robot must be installed on a customized machine, or even a guide rail, you may need to know its weight to design the corresponding support.

8. Brake and moment of inertia

Basically, each robot manufacturer provides information about its robot braking system. Some robots have brakes on all axes, while others do not have brakes on all axes. In order to ensure an accurate and repeatable position in the work area, a sufficient number of brakes are required.

In another special case, in case of accidental power failure, the axle of the load-bearing robot without brake will not lock, which may cause an accident.

At the same time, some robot manufacturers also provide the rotational inertia of the robot. In fact, this will be an additional guarantee of design security. You may also notice the torque applied to the different shafts. For example, if your action requires a certain amount of torque to complete the work correctly, you need to check whether the maximum torque applied to the shaft is correct. If the selection is incorrect, the robot may shut down due to overload.

9. Degree of protection

According to the use environment of the robot, select a standard that reaches a certain protection level (IP level). Some manufacturers provide different IP protection levels for the same robot for different occasions. If the robot works in food related products, drugs, medical devices, or flammable and explosive environments, the IP level will be different.