As an industrial robot, palletizing robot is one of the key emerging industries for China to impleme

Cooperative palletizing robot, an industrial robot, is a key emerging industry in China's implementation of the manufacturing power strategy. The development level of robot industry is an important symbol to measure a country's innovation ability and industrial development level.

Market outlook 2022-09-21

With the development of automatic stackers, automatic stackers are used more and more widely, and mo

The labor intensity of manual stacking is high, and the turnover rate of post labor is high, which has a serious impact on production management. With the development of science and technology, the appearance of automatic stacker saves time and energy for product stacking, and can better help enterprises to complete transportation tasks.

Market outlook 2022-09-29

The advantage of this robot is that it can automatically identify what is a cooperative palletizing

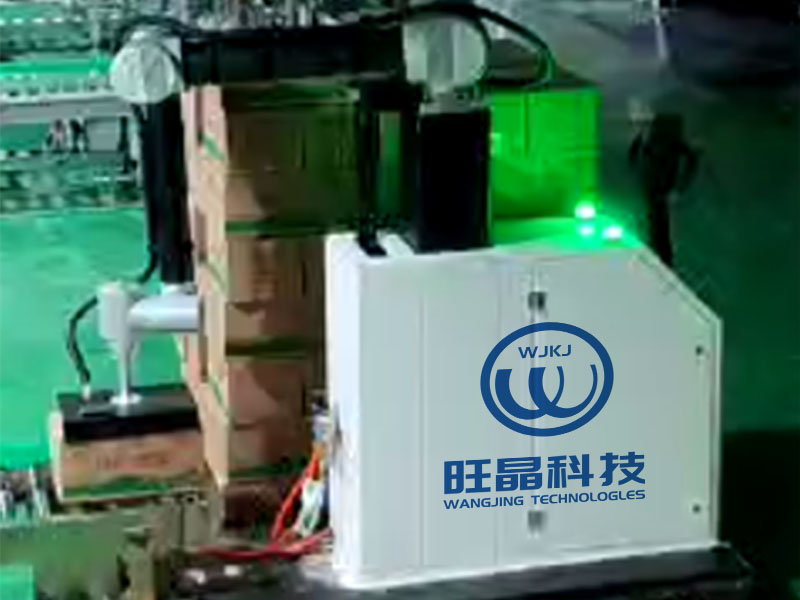

The stacking work is completed in the form of a mechanical arm. Stacking is one of the most promising cooperative robot applications, but before introducing in detail, let's start with a simple definition. Palletizing or palletizing refers to the act of placing products on pallets for shipment or storage in the logistics supply chain. Ideally, products should be stacked in a way that maximizes the weight and volume of products under load, and they should be stable enough to prevent products from moving, dumping or squeezing each other.

Market outlook 2022-10-06

Stacking robot slowly replaces manpower

The palletizing robot presents a diversified development trend. It can replace the staff working in dangerous, continuous high temperature, toxic and harmful substances and other harsh environments, while ensuring product quality and improving work efficiency

Market outlook 2022-09-18

With the continuous development of intelligence and informatization, the future development directio

The stacking manipulator has a material stacking sequence and arrangement setter, which simulates some action functions of the hand and arm. According to fixed procedures, it can automatically and neatly stack packaged goods of different sizes on pallets or production lines. Stacking manipulator can replace manual labor, realize mechanization and automation of production, operate in dangerous environment, and protect personal safety.

Market outlook 2022-09-23

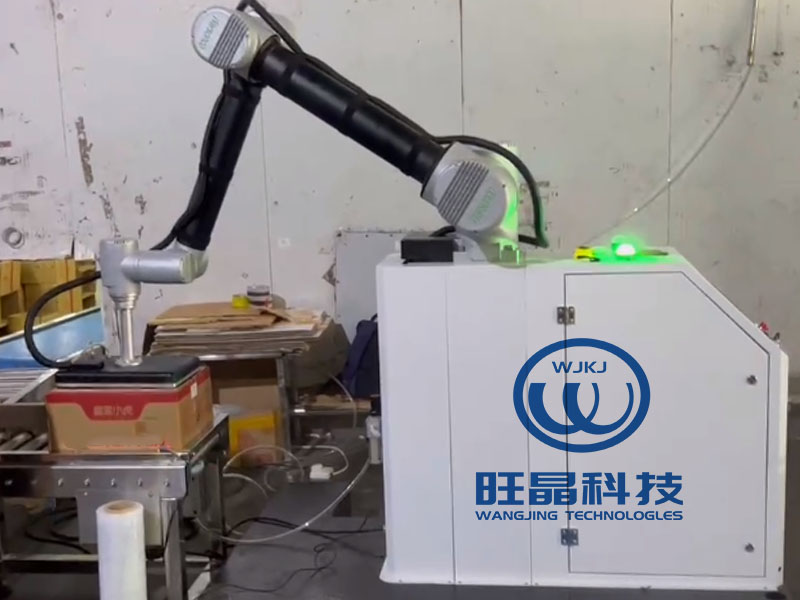

Portable palletizing robot goes to war to solve the problem of small factory space

With the mature application of artificial intelligence, big data, cloud computing and other technologies, robot manufacturing enterprises have enjoyed huge scientific and technological dividends. According to the statistical report of relevant data, the number of industrial machines put into use in the world has reached 3 million, with a year-on-year growth of 10%. It is estimated that by 2024, the number of new industrial robots in the world will reach about 500000/year. From the data, the demand for robots will increase year by year. On the one hand, robots improve work efficiency, on the other hand, the application of robots also reduces the pressure of manual management in enterprises.

Market outlook 2022-09-30

Reasons why enterprises choose palletizing robots to replace traditional production lines

The continuous increase of labor costs has formed a development trend, and it is difficult for manufacturing enterprises to recruit people. In the face of difficulties, many enterprises are moving towards automation technology production lines. Among them, the automatic technology complete equipment production line of palletizing robot is more popular and has developed rapidly in recent years.

Market outlook 2022-09-19

Through intelligent upgrading, palletizing robot can reduce labor cost and improve enterprise compet

Stacking robot can reduce labor cost and enhance enterprise competitiveness. Due to the high demand and dependence on labor in manufacturing, the labor cost in manufacturing is relatively high

Market outlook 2022-09-28