Portable palletizing robot goes to war to solve the problem of small factory space

With the mature application of artificial intelligence, big data, cloud computing and other technologies, robot manufacturing enterprises have enjoyed huge scientific and technological dividends. According to the statistical report of relevant data, the number of industrial machines put into use in the world has reached 3 million, with a year-on-year growth of 10%. It is estimated that by 2024, the number of new industrial robots in the world will reach about 500000/year. From the data, the demand for robots will increase year by year. On the one hand, robots improve work efficiency, on the other hand, the application of robots also reduces the pressure of manual management in enterprises.

Our company is a high-tech enterprise, integrating the R&D, production and sales of robot products, focusing on technology, and committed to providing one-stop automation solutions for enterprises across the country. With the improvement of technical level, today's product categories are becoming more and more rich. Not only are there parallel robots and a full range of cooperative robots, but also cutting-edge products such as robot control systems and industrial vision robots have been developed on this basis. In recent years, all walks of life have put forward higher requirements for improving quality and efficiency. Therefore, robots produced by our company are widely used in medicine, 3C, food, package printing, daily chemical, e-commerce and other fields. Adhering to the business philosophy of "keeping improving and pursuing excellence", we make great efforts in product quality to ensure that every product listed can stand the test of time. At this stage, the robots produced by the company have been exported to more than 50 countries and regions in Europe, America, the Middle East, Southeast Asia, etc., and have been highly appreciated and recognized by many enterprises.

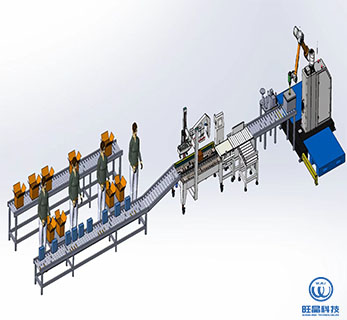

It is worth mentioning that our cooperative robot - palletizer stands out among many products. Its appearance not only solved the problem of insufficient manpower at the end of the packaging carton of the assembly line, but also helped enterprises reduce economic pressure. At present, the manual handling of the end of the packaging carton in the manufacturing assembly line is often three or two shifts. After using the stacking robot, it can run in one shift, which can save two salaries. In a way, its appearance caters to the development needs of enterprises under the epidemic situation.

It is designed according to ergonomics principle and automatically palletizes to easily realize one-stop storage and transportation. Integrated design and intelligent programming are adopted internally, which is simple and convenient to operate, and can increase the working efficiency to more than twice. In addition, it occupies a small area, and can be used freely for the end of small assembly line packaging cartons. Support the quick switching mode of multi-functional scenarios, human-machine cooperation, dual machine cooperation, multi machine cooperation and other random choices to help enterprises achieve flexible production. In addition, compared with similar products, the performance of the palletizing robot is also very stable. It not only supports level 10 collision detection, but also supports sensor safety detection. 16 safety I/O interfaces are configured, so that the safety function will not be lost in case of a single failure, thus reducing the difficulty of maintenance.

In the era of rapid development, whoever has high efficiency can be competitive. The appearance of palletizing robot has solved the problem of palletizing at the end of the packaging carton of the assembly line, and has added full power to improve the quality and efficiency of enterprises!