Characteristics and Research Scenarios of Stacking Robot

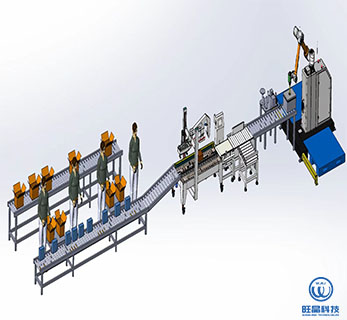

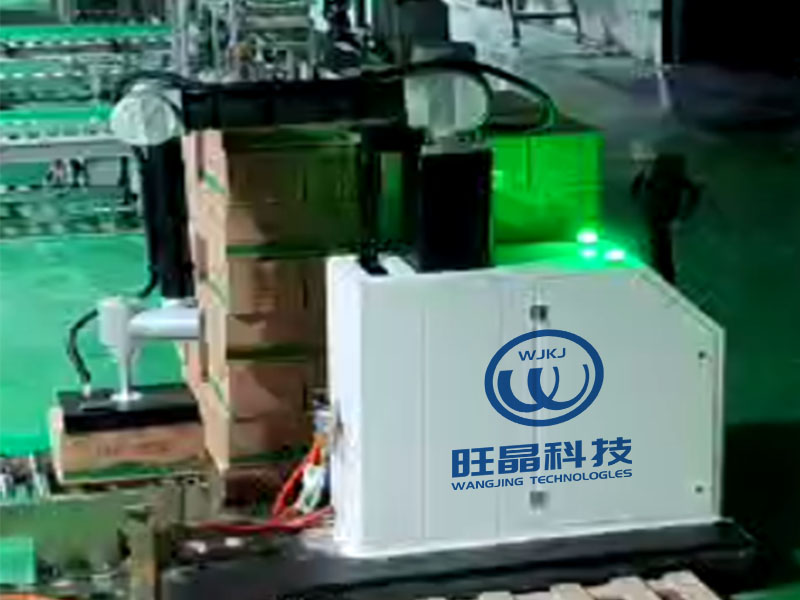

The cooperative palletizing robot is mainly composed of manipulator, wrist, wrist adjustment mechanism, arm mechanism, rotator, servo drive system, base and other components, with four degrees of freedom of body rotation, horizontal and vertical movement of arm mechanism, and wrist rotation. What are the main components and application research scenarios of the system with the cooperative palletizing robot?

Market outlook 2022-09-20

What should we pay attention to when small and medium-sized enterprises choose cooperative robots?

Collaborative robots are used in the process of sorting out enterprise related emergencies, and can complete collaborative work that can only be completed by multiple people at a faster speed. This kind of robot is suitable for enterprises with gradual development of industrialization and scale, and can solve many difficult and complex problems. So what should enterprises pay attention to in the early stage of selecting cooperative robots?

Market outlook 2022-09-22

For example, the biggest advantage of manual palletizing robot is that it is more convenient and fas

With the need of industrial production, palletizing robots are used by more and more industries. So why can palletizing robots be accepted by more and more enterprises? What are the advantages of using palletizing robots over manual palletizing?

Market outlook 2022-09-22

So, what is the significance of this technology's automatic palletizer?

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

Market outlook 2022-09-22

This is the use method of a fully automatic stacker

Now, more and more enterprises use automatic stackers. It is worth noting that there are many skills to understand and master in the process of using automatic stackers.

Market outlook 2022-09-28

Robot is one of the important characteristics of palletizing robot in intelligent manufacturing

Stacking robot Mechatronic high-tech products can complete the high automation of the system and provide necessary maintenance for equipment and operators.

Market outlook 2022-09-23

With the development of artificial intelligence technology, the role of unmanned cooperative stackin

The role of robots in industry has replaced human workers in many manufacturing industries. Machines like mechanical arms make it possible for humans to perform tasks with brute force before automation. Now they have replaced heavy lifting and precision assembly. The use of industrial robots can not only help create products, but also reduce waste and improve safety.

Market outlook 2022-10-06

Collaborative robots guide future factory changes! Compared with traditional industrial robots, it h

The future intelligent factory is created by the harmonious coexistence of people and machines. It requires robots to cooperate with humans and complete different tasks with humans. This includes not only the traditional tasks of "people can't do it, people don't want to do it, and people can't do it well", but also complex tasks that can reduce human labor intensity and improve the quality of human life

Market outlook 2022-09-18