As an industrial robot, palletizing robot is one of the key emerging industries for China to impleme

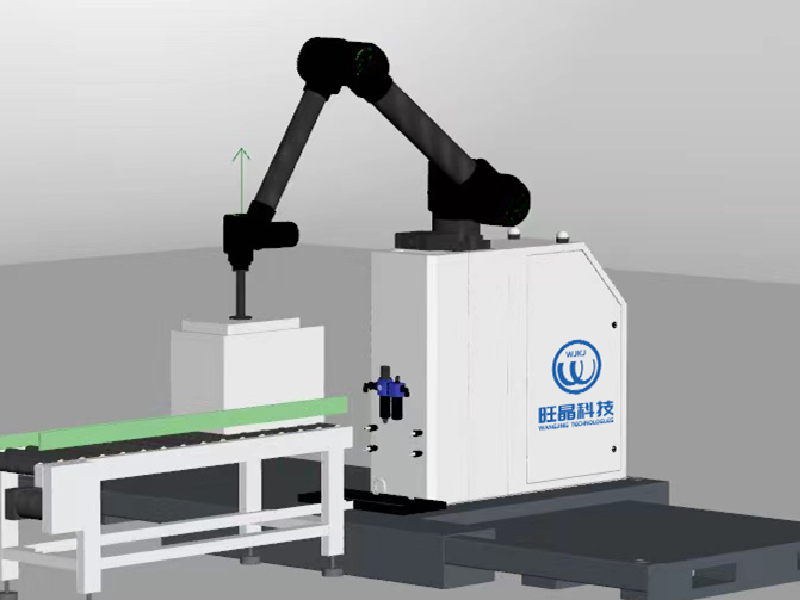

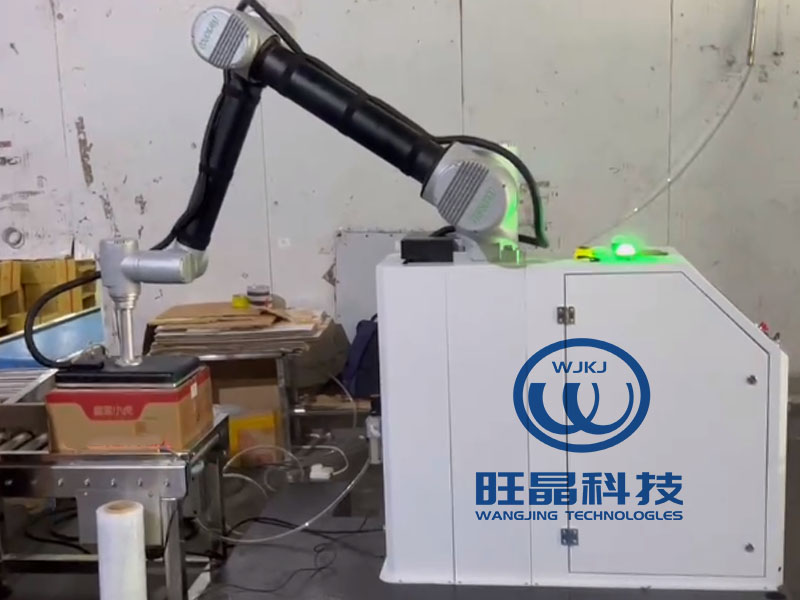

Cooperative palletizing robot, an industrial robot, is a key emerging industry in China's implementation of the manufacturing power strategy. The development level of robot industry is an important symbol to measure a country's innovation ability and industrial development level.

With the promotion of industrial transformation and upgrading in China, reducing the human cost and production cost of traditional manufacturing and improving product quality and performance have become the main goals. Industrial robots are the most important equipment for intelligent manufacturing.

In order to promote the progress of robot technology in China and expand the competitive advantage of domestic robot enterprises in the international market, China has listed industrial robots as key development projects in the future. With the strong support of governments at all levels, China's industrial robots have formed a complete industrial chain, and the market scale is expanding year by year. At present, China's industrial robot market accounts for one third of the world market share, with sales reaching 6.23 billion US dollars, ranking first in the world market for six consecutive years. In the past, the core components of robots were the core factors that restricted the development of industrial robots in China for a long time. However, with the rapid development of domestic manufacturers, China has made technological breakthroughs in controller, servo motor, reducer and other core components to varying degrees. The palletizing robot has stable quality and high cost performance. This means that China's material handling machinery has also moved from the original low-end stage to the high-end intelligent stage with the industrial upgrading, promoting the industrial structure to a new level.

So in the future, some new technologies will gradually replace people to do simple, manual and tedious work. In recent years, the concept of robot has been increasingly integrated into everyone's life and work. It is reported that robots have taken over some production and people's lives. With the rapid development of household storage robots, the development mode of intelligent logistics will attract the attention of the logistics industry. If the cost can be controlled within a generally acceptable range, the development prospects of warehousing robots will be immeasurable.

In general, China's industrial robot manufacturers still focus on system integration, and their products are mostly low-end products, such as handling robots, palletizing robots, sorting robots, etc. There is still a certain gap between high-end fields such as collaboration and major international manufacturers. In some traditional industrial fields, enterprises have relatively low requirements for the performance and accuracy of industrial robots, and household robots can fully meet the needs of enterprises. Therefore, domestic manufacturing enterprises should accept domestic industrial robot products with a more positive and inclusive attitude, help the development of domestic industrial robot manufacturing technology, provide opportunities for domestic industrial robots to penetrate from low-end to high-end fields, and finally achieve high quality like collaborative stacking robots