The market scale of industrial robots in China has reached 17.3 trillion yuan, and stacking robots h

The disadvantages of manual palletizing of cooperative palletizing robot are pointed out: the palletizing form is irregular, the palletizing is often reversed, and there are potential safety hazards. In the loading process, due to the irregular stacking form, the loading capacity is low and the transportation cost is high. Low stacking efficiency and high labor cost. Personnel management is a thorny problem.

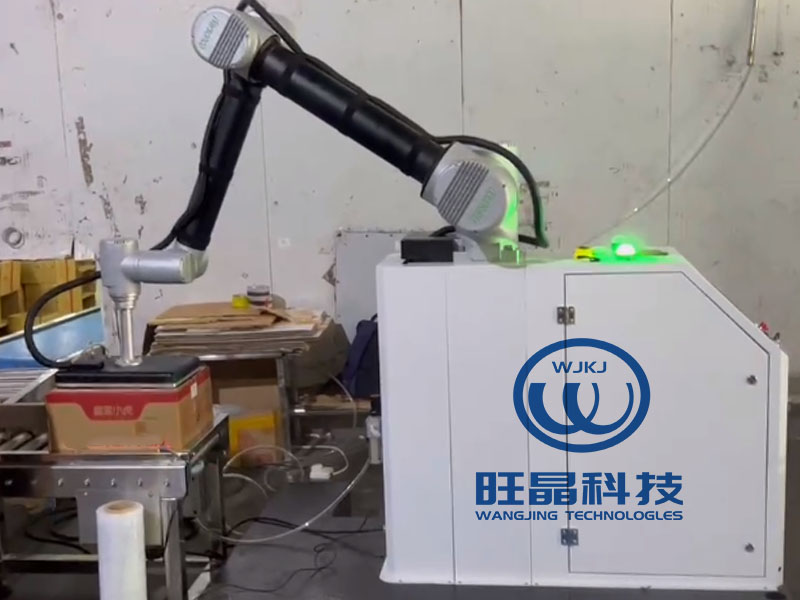

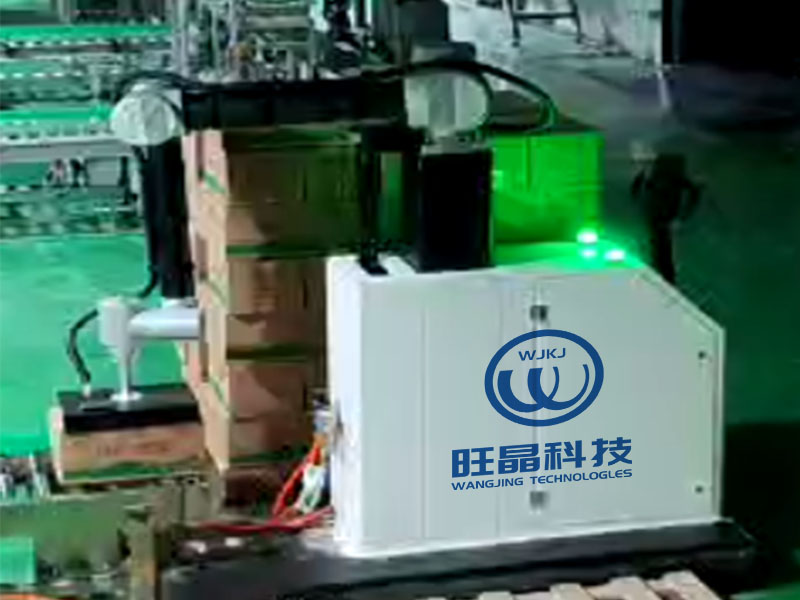

Cooperative stacking: the advantages of this method are that the stacking form is neat and compact, and the hidden danger of stacking is eliminated. The loading capacity is increased by 6%, effectively reducing the transportation cost. The palletizing efficiency is increased by 3 times, 6 palletizing workers are reduced, and the annual production cost is saved by about 500000 yuan. Robot management only requires the operation and maintenance of technicians, which can reduce the human resource expenditure of enterprises and reduce the management difficulty. In order to make production faster and more accurate, packaging manufacturers are increasingly inclined to use automation solutions on the front and back platforms.

Among them, robot palletizing can ensure the continuity of later production, improve output and reduce downtime. Compared with the traditional stacker, the stacker robot has several key advantages. They take up less space, can withstand very heavy loads, and can handle different types of products and different formats of pallets. The robot is especially suitable for stacking bagged products, such as rice. If there are three or four production lines with slow production speed, it is more suitable to use robot palletizing unit. Combining the power and speed of the robot is its advantage. Compared with other palletizing robots at the same level, the four axis robot designed for whole layer palletizing and unloading can handle heavier and larger products and loads at a faster speed.

Robot's outstanding ability is its flexibility. Through specially designed clamps, it can stack and unload various packaged goods, from bags, cartons and pallets to corrugated cartons, crates and cans. According to different applications, the production speed of the palletizing robot can reach 1900 sets per hour.