This is the important significance of our country to the automatic stacker

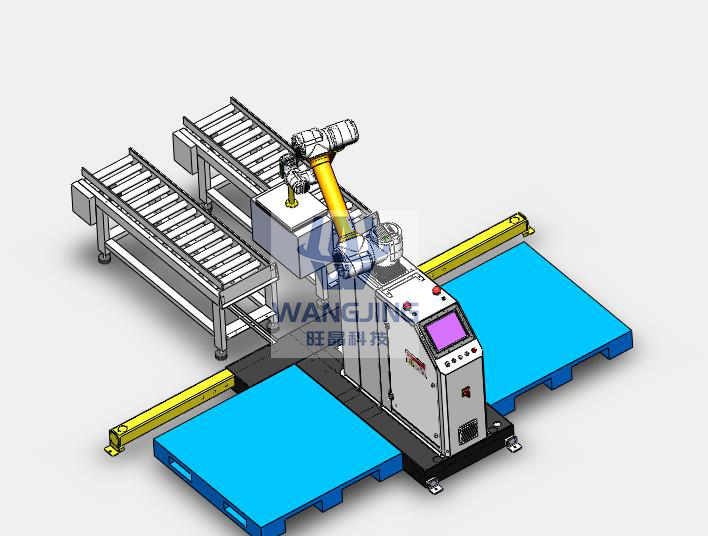

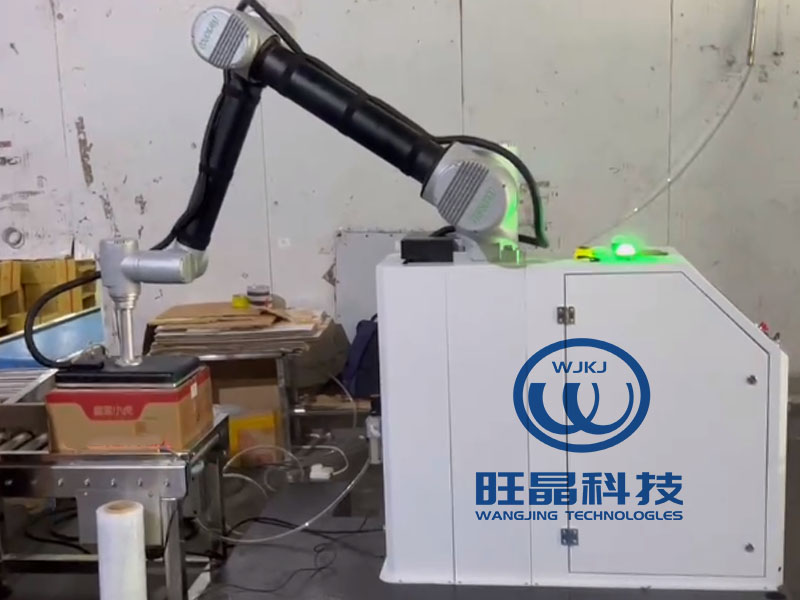

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

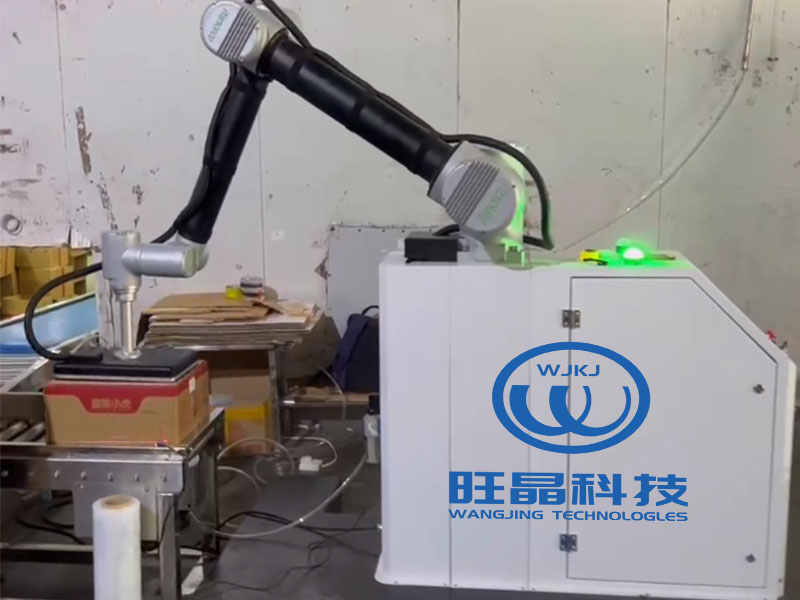

In the era of mechanized production, from ancient times to the present, we can find that through our continuous use of system automation machinery, we can maximize the use of labor and production management efficiency of related products. Now the appearance of automatic stacker has also realized a great liberation of human resources in social life. In a factory, the production line of an enterprise needs many workers, and different jobs are divided into different groups. Now there is a code stack robot, which can save the manual use of a process, reduce the use cost of the factory, and speed up the production efficiency of products. This is a great progress for the whole world development history. This success has liberated a batch of labor force, and the production efficiency of products has been continuously improved, which is also a great benefit for manufacturers.

Automatic stacker is an industrial machine which has been widely used in recent years. It consists of three parts: chassis, stacker main body and conveyor. The position of the equipment can be adjusted freely according to the user's site conditions, from the initial step of the product to the offline. The appearance of automatic stacker represents a great progress in industrial automation, and also provides a great opportunity for social development and labor liberation. As an important auxiliary equipment for industrial assembly line production, its existence can reduce the total number of workers needed on the assembly line and improve industrial efficiency.

In the era of mechanized production, from ancient times to the present, we can find that through our continuous use of system automation machinery, we can maximize the use of labor and production management efficiency of related products. Now the appearance of automatic stacker has also realized a great liberation of human resources in social life. In a factory, the production line of an enterprise needs many workers, and different jobs are divided into different groups. Now there is a code stack robot, which can save the manual use of a process, reduce the use cost of the factory, and speed up the production efficiency of products. This is a great progress for the whole world development history. This success has liberated a batch of labor force, and the production efficiency of products has been continuously improved, which is also a great benefit for manufacturers.