Innovation leads technology enabling/technology leads "intelligence" to build the future

With the continuous development and change of society, more and more enterprises have clearly realized that science and technology and innovation have become the most strategic key variables in the development of countries around the world. Who has mastered advanced science and technology can have greater voice in the market. Especially in the face of the severe reality that "Made in China" has been suppressed and contained in the international market, the power of science and technology and innovation is more important.

Scientific and technological policies have been put into practice

Dongguan Wangjing Technology Co., Ltd. was established in December 2021. With industrial robots as its core technology, it is a national high-tech enterprise focusing on the research, development, production and sales of industrial robots. Its products cover a series of parallel robots, a full range of cooperative robots, industrial vision and robot control systems. Once listed, it has cooperated well with many industrial bases. Its products are widely used in medicine, 3C, food, printing bags, daily chemical and other industries. It is an internationally first-class automation solution provider with excellent reputation.

Effective stacking operation quality of scientific research and development

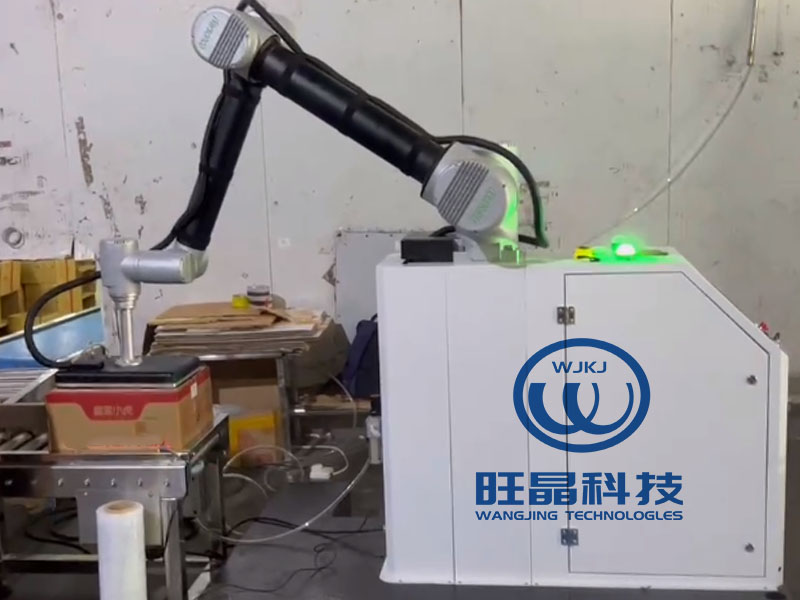

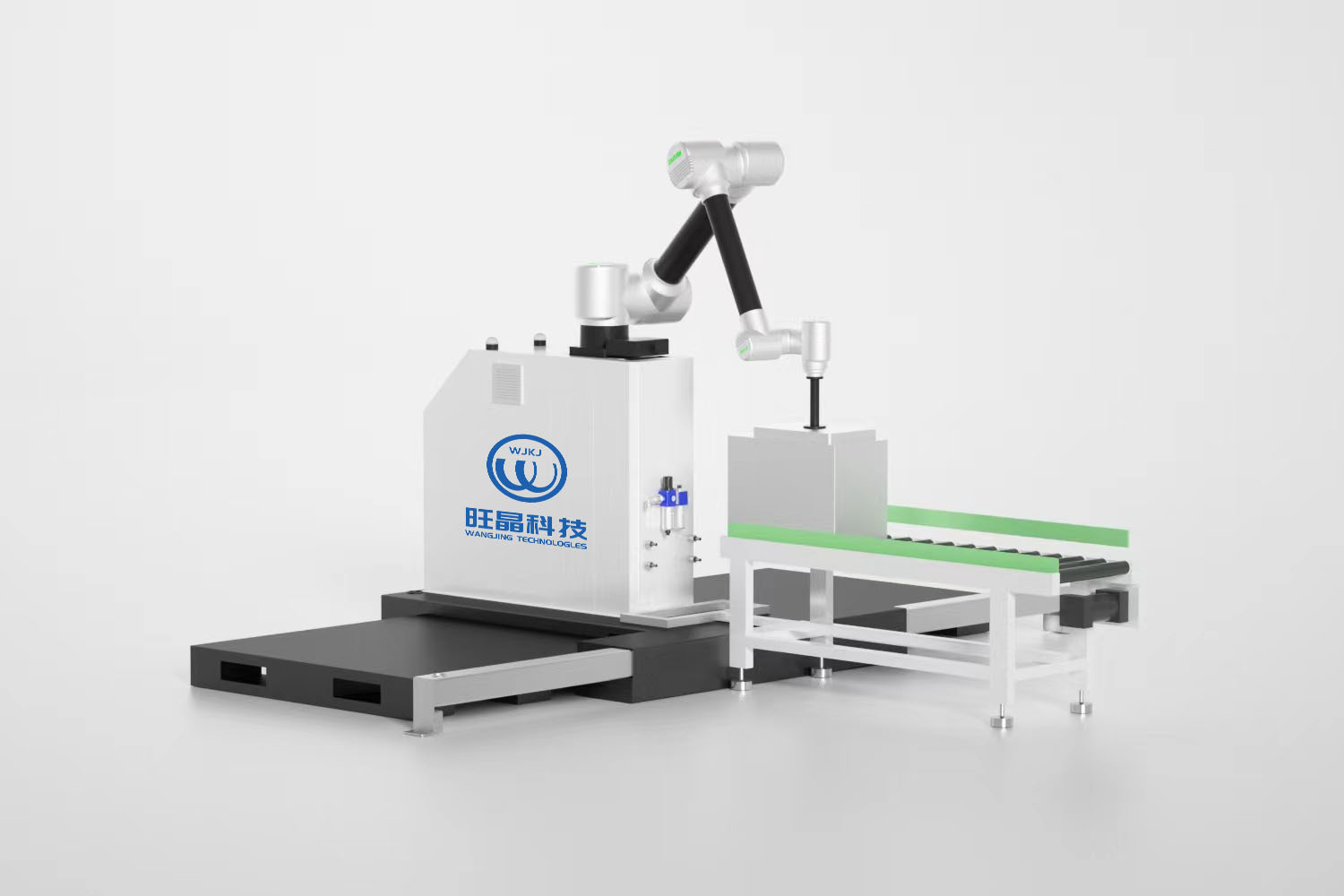

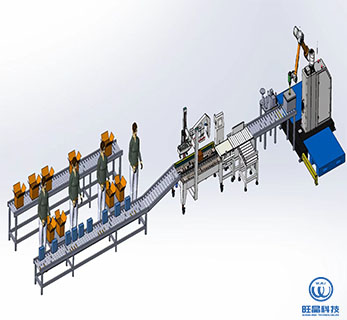

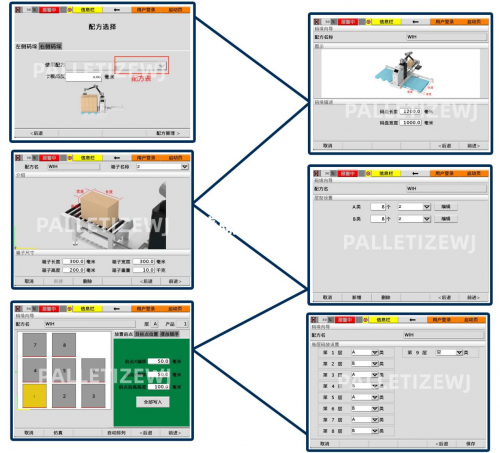

WJKJ-MD cooperative palletizing robot is the main product of Dongguan Wangjing Technology Co., Ltd. in the palletizing cooperative robots. It is simple in size, light in weight, only 62kg, and easy to load and transport. It has excellent adaptability in various large, medium and small working environments and standardizes industrial operations. At the same time, WJKJ-MD equipment adopts advanced control conversion technology to simplify and facilitate the core code, which is directly reflected in the greatly reduced difficulty of machine deployment and operation and is extremely friendly to the programming ability of technical operators. Under the formula management and visual design led by Wangjing Technology, the operators who have only been trained for a few days can also flexibly set up multiple different packaging schemes and switch with one button, greatly reducing the time for changing production lines and improving work efficiency. This is an excellent choice for palletizing in the current industrial environment where efficiency and safety are pursued simultaneously.

Scientific and technological achievements enable industrial palletizing automation

From August 24 to 26, 2022, the industrial palletizing robot of Wangjing Technology will show its skills at the 2022 Global High end Food Exhibition supported by China Nonstaple Food Circulation Association and hosted by Beijing Longpinxi Exhibition Co., Ltd. At the event site, WJKJ-MD palletizing robot developed by Dongguan Wangjing Technology Co., Ltd. will help the rear end of the production line to achieve automatic packaging and palletizing, and the activity layout will be in order, Help many food enterprises participating in the exhibition to realize the construction of unmanned factories.

In addition, Dongguan Wangjing Technology Co., Ltd. is also the backbone of China's industrial automation construction. Since its products came out, it has carried out long-term and close friendly cooperation with many industry leading enterprises with large stacking quantities, such as OPPO, Wangwang, Jinmailang, Sanjiu Pharmaceutical, etc., especially the PalletizeWJ number stacking machine workstation with the exclusive technical patent of Wangjing Technology, which is an internationally famous automation manipulator, It has been favored by more than 40 enterprises including the above enterprises, helping China's industrial palletizing automation to a new level.

Science and technology are the primary productive forces. The emergence and application of cooperative palletizing robots have brought more possibilities for industrial operations. Let's lay out automated palletizing operations together to achieve a landmark improvement in work efficiency.