There is no solution to this problem at present. What are the shortcomings and drawbacks of cooperat

From the perspective of customers in the domestic market, due to the high flexibility and low cost of cooperative robots, SMEs are the main force in using cooperative robots. In addition, from a practical perspective, China's aging trend is becoming more and more obvious, and domestic labor costs continue to rise. The manufacturing industry is trying to find a more flexible and efficient production mode to alleviate the labor shortage and cope with the rapidly changing market. This also provides space for the development of small and medium-sized enterprises' cooperative robots.

The rise of collaboration can help people enjoy better quality of life and reduce working hours. For employers, cooperative robots can undertake the most dangerous tasks to reduce the risk of injury and labor costs. The disadvantage of cooperation is that robots cannot undertake all the tasks completed by humans. Over time, they may be able to handle many manufacturing tasks completed by humans. What scenarios are the shortcomings of cooperative robots applicable to?

1. In terms of fine tasks, cooperative robots still have limitations.

2. Cooperative robots cannot completely replace humans.

3. The cooperative robot replaces the labor force, which is expensive.

4. These devices can enable people to work more efficiently, and people will feel worthless.

5. The number of employees is reduced, and the living space is squeezed.

6. The cooperative robot has improved the safety of the workplace, which is amazing.

7. The cooperative robot can complete the programming in half an hour, and people can close themselves.

8. Cooperative robots are more consistent and accurate than human beings, and stimulate people's desire to win or lose.

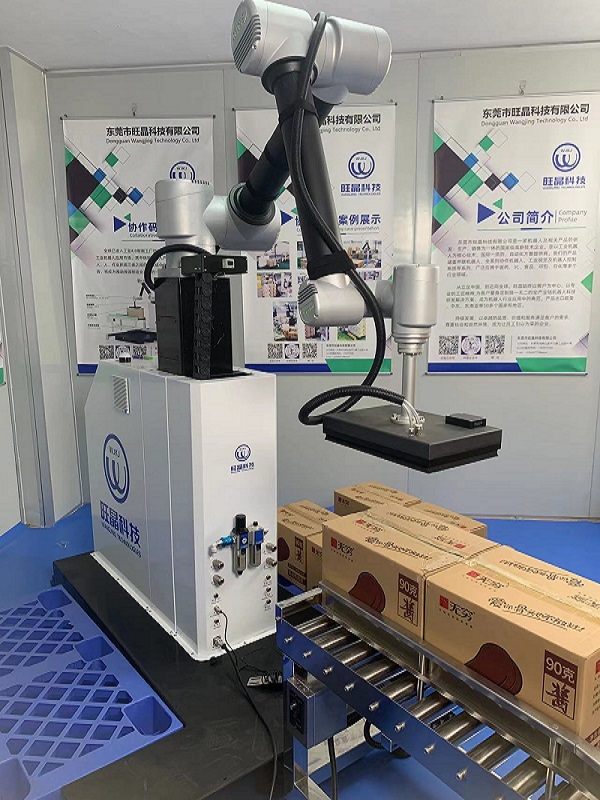

The rise of robots can be attributed to their ability to handle any dangerous, boring or dirty task. Cooperative robots can be used in safe areas. When someone enters the area, the cooperative robot can be trained to slow down. Then, when people get too close, it will follow them and stop working. Over time, cooperative robots can be trained to imitate the way humans perform different tasks and tasks.

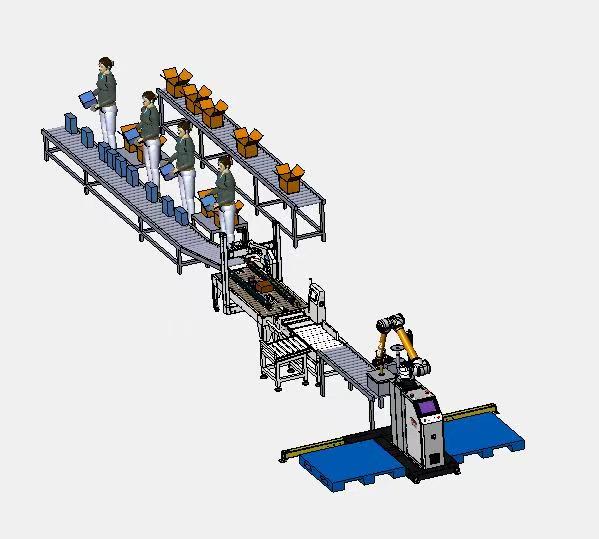

What scenarios are cooperative robots used in? The application market of cooperative robots is exploding, with more and more applications, not only in the industrial field. Cooperative robots are mainly used in automobiles and 3Cs. In addition, cooperative robots can also be used in pharmaceutical, petrochemical and other commercial fields. At present, logistics, warehousing and medical fields have been widely used in the commercial field.