Cooperative mobile palletizing robot can improve efficiency and save costs

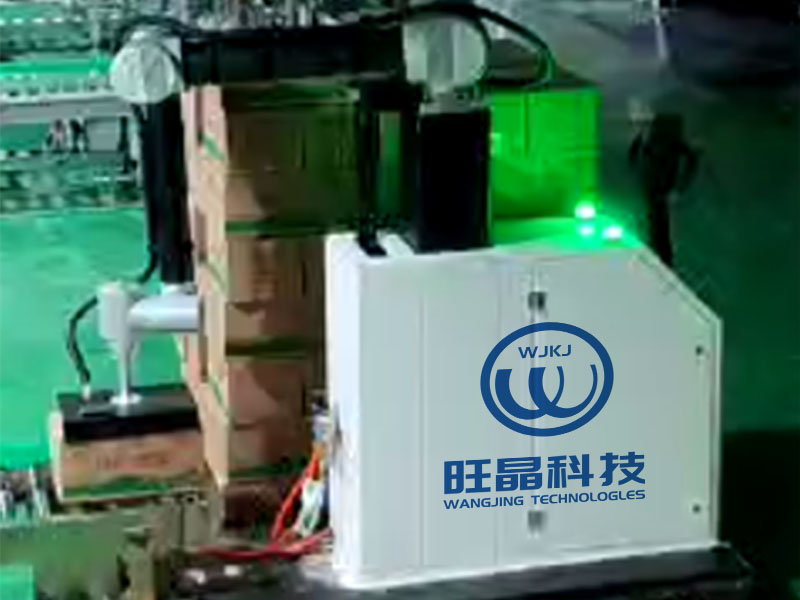

In many industries, collaborative palletizing robots have been used to replace manpower and simplify work. It is generally used for lightweight practical product packaging. Collaborative intelligent robots put objects or services into small boxes or trays. The intelligent robot of automobile palletizing cooperation can accurately stack small boxes, aquariums, packaging bags, pallets, and packaging cartons in the medium and heavy load areas in the pallet.

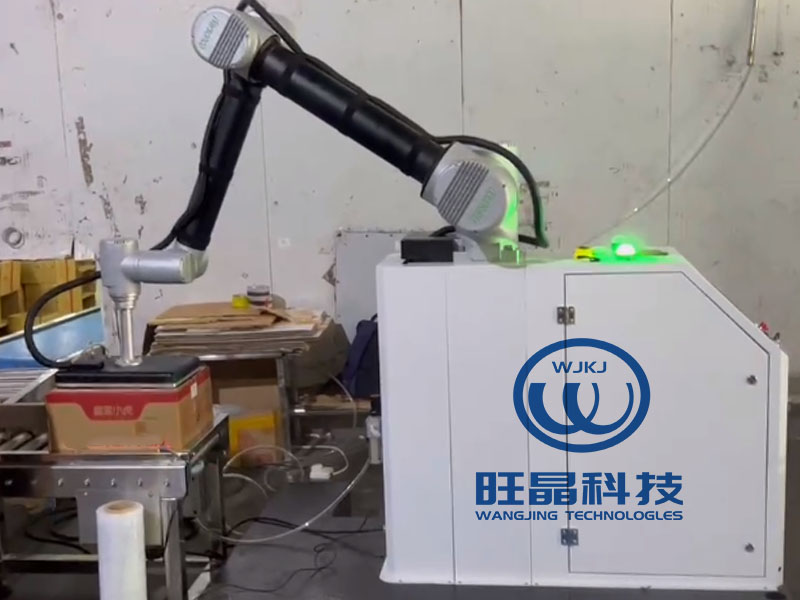

Cooperative palletizing robots can provide reasonable and correct solutions to deal with ergonomically harmful repetitive work. With the support of the light cooperative mechanical arm, the lifted objects can be transported, which helps prevent workers from being injured.

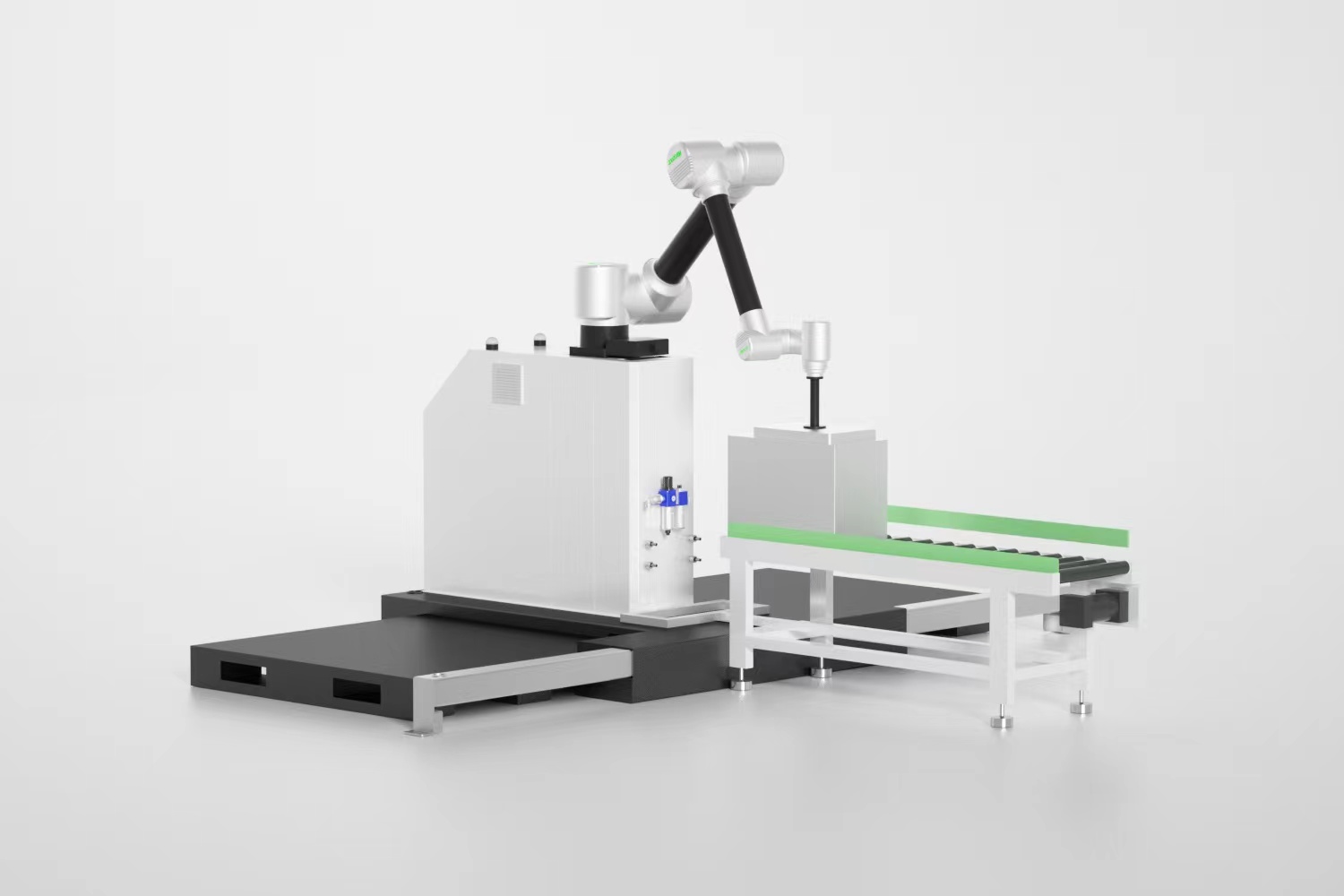

The palletizing robot has many characteristics, including: the multi-functional cooperative palletizing robot can be reconfigured and reprogrammed to meet the requirements of various gravity gradients. Due to its lightweight size and design, once the work content requirements are reduced, the manipulator can be used to perform new tasks.

Reduce maintenance costs

The cooperative mobile palletizing robot's parts are equipped with a low wear gearbox. Due to its rugged and streamlined design, the daily maintenance interval of the mobile stacking robot is long.

It has high strength and efficiency.

The cooperative palletizing robot can quickly lift the goods, reduce the cycle time, improve the palletizing rate of small boxes, and win higher work performance.

Compact design

Its convenient size can quickly integrate the packaging cooperative mobile palletizing robot into the current system to simplify performance and improve work efficiency.

The cooperative mobile palletizing robot brings many benefits, such as simplifying steps, improving work efficiency and controlling costs. The palletizing robot palletizing production line not only improves product quality and labor efficiency, but also ensures life safety, optimizes the labor environment, and alleviates labor efficiency; It is also of great significance to save raw material consumption and reduce costs.