Advantages of industrial palletizing robot

The cooperative palletizing robot has developed rapidly in many fields with its own advantages, and it often appears in many industries. The palletizing robot has the characteristics of complete models and specifications, stable operation, low energy consumption, simple operation, and high automation level, which improves the automation level of palletizing and is beneficial to easing the labor force.

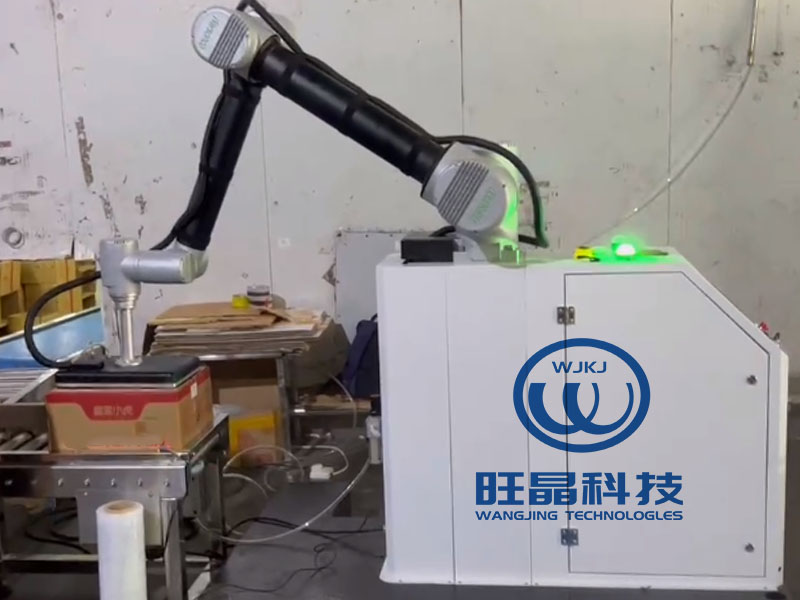

The characteristics of industrial palletizing robot The industrial palletizing robot, to put it bluntly, is an intelligent robot that automatically codes the packaged goods in the pallet. There is no doubt that the application of palletizing robot will greatly improve the production efficiency, reduce the labor intensity of workers, and in some extreme working environments, it also has the effect of reasonable protection for the personal safety of workers. The characteristics of the cooperative palletizing robot are as follows:

1. The models and specifications are complete.

With the rapid development of high-tech industrial automation, many light industries have successively produced according to automated assembly lines. Cooperative palletizing robots are widely used in automobile manufacturing, decoration industry, food enterprises, chemical manufacturing industry, feed industry, medical industry, electronic industry, etc. The palletizing robots have strong adaptability, and the completion of non-standard customization can meet the needs of various fields.

2. The total area is small and the actual operation is convenient.

The design and analysis of the wrist and abdomen structure of the industrial palletizing robot can flexibly carry out the palletizing work in space. The industrial palletizing robot can also be equipped with a mechanical interface at the end of the actuator, which can remove and replace the force point, so that the cooperative palletizing robot can be used in a large number of places, and operators can use the control board to carry out long-distance actual operations.

3. Low energy consumption.

The shell of the industrial palletizing robot is made of raw materials that are relatively light and meet the requirements of compressive strength, so that the human body is not too heavy. Generally, the output power of the pedal type palletizer is about 26KW, while the output power of the industrial palletizing robot is about 5KW, which greatly reduces the use cost of customers.

4. Compact structure, convenient maintenance.

The cooperative palletizing robot mostly adopts a four axis overall design, with compact structure and few parts, so the equipment failure rate of parts in use is low, and it can be easily maintained. The above characteristics of industrial palletizing robot are the characteristics of cooperative palletizing robot. All operation processes of cooperative palletizing robot can be carried out from the control box screen, which is simple and convenient to operate, complete automatic and digital tasks, and improve the production and manufacturing process of various industries.