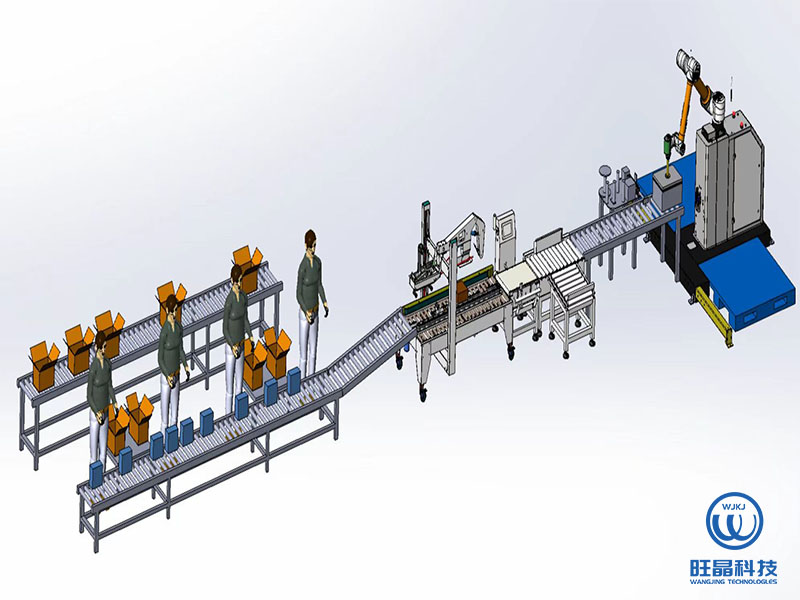

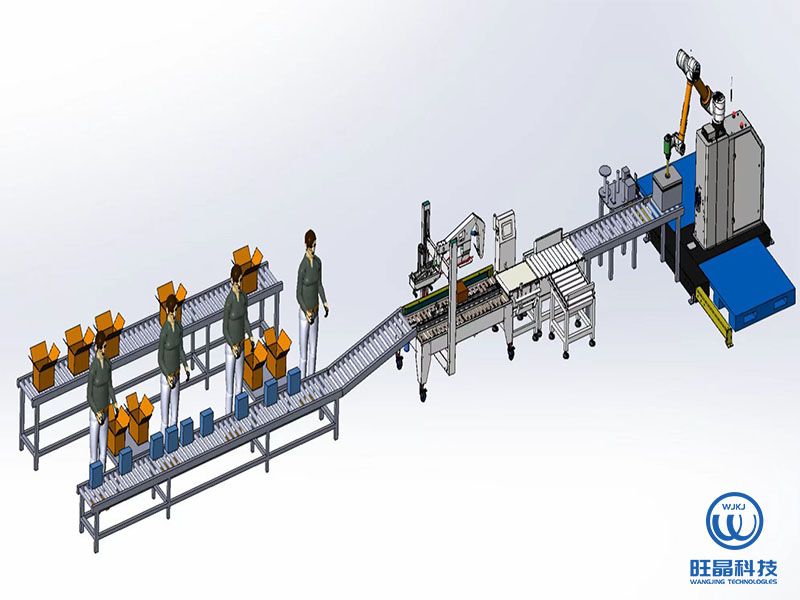

In recent years, with the rapid development of international trade, automatic packing machines help

Automatic packaging machine is a kind of packaging equipment with high degree of automation. Usually, the undeveloped and shrunk cartons are unfolded, and then the products are put into the cartons. The whole process is automatically carried out by the automatic sealing machine without manual intervention.

In the automatic packaging assembly line, the packaging machine is important for the operation of all systems. Although the outer packaging equipment is not a machine for directly producing products, it is indispensable for the automation of production and processing.

Automatic packaging machine is a convenient automatic packaging machine. It uses fast delivery equipment to package various containers, such as plastic flat bottles, round bottles, irregular bottles, glass cans of various specifications, round bottles, elliptical bottles, square cans, paper barrels, etc. In addition, wooden packing boxes with partitions are also used.

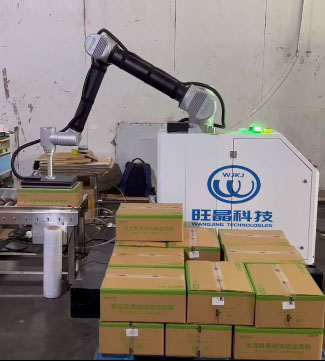

The automatic boxing machine automatically sorts the outer packaging, puts it into the activated carton, and then loads the self-adhesive sticker and other behaviors. All gestures are fully automatic.

Most automatic packaging machines have selected new structures, including full container equipment, full row equipment, loading equipment, boxing equipment and other functional control modules, which are equipped with matching functional attitudes. All equipment are assembled on the same network server cabinet. The blanks of the full case equipment are placed above, the filling equipment is placed below the full case equipment, the whole row of equipment is placed in front of the filling equipment, and the box flushing equipment is placed behind the filling equipment.

Select P.L.C+touch screen control.

It is equipped with alarm and shutdown for bottle shortage, and no safety device is installed without bottle.

It greatly facilitates the rapid operation of processes, management programs, and reduces the cost of manufacturing personnel and labor productivity. Automatic packaging machine is an indispensable equipment for large-scale production and processing of automation enterprises.