Correct operation method of automatic production line

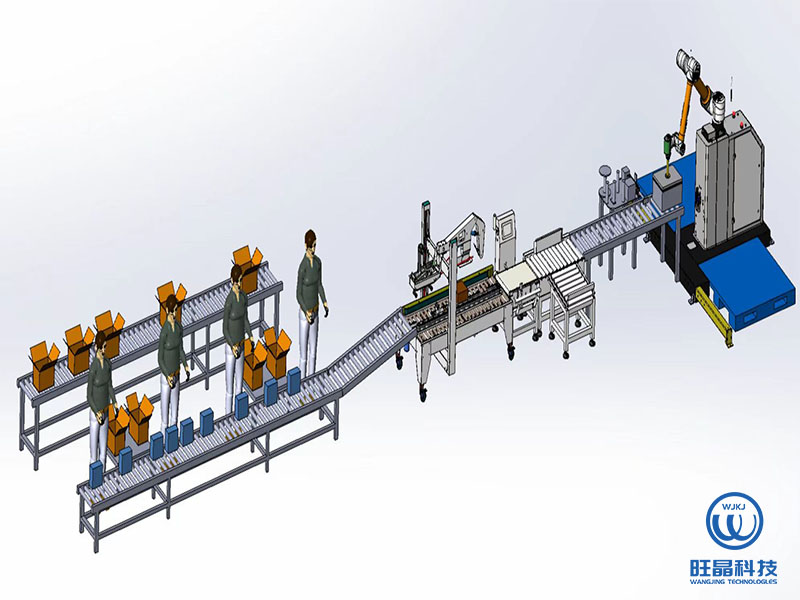

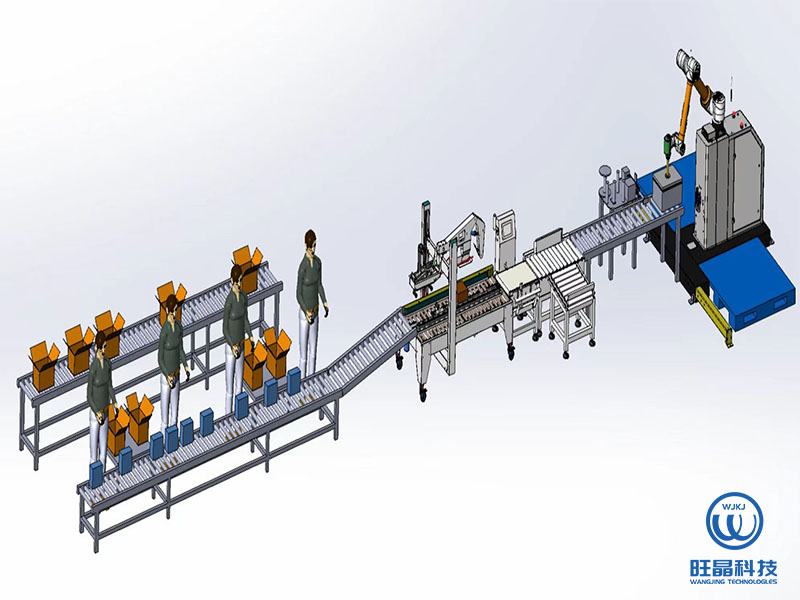

In the period of continuous development of modern science and technology, automated production has entered most of the sales markets, and manual production and manufacturing has gradually been replaced by automated assembly lines of artificial intelligence technology. Now, I would like to introduce the appropriate operating steps of belt transportation production lines in automated assembly lines.

Before running the belt conveyor line, first ensure that the belt conveyor line equipment and transport objects are in a safe and sound state; Workers are outside the conveyor line, and then check whether there is any problem with the matching positions of the belt conveyor line, whether there are other items, and whether there is any problem with all electrical circuits. Only under normal conditions can the belt conveyor line be put into operation. The last step is to check that the difference between the power supply voltage and the rated current of the equipment cannot exceed 5%.

The following practical operations must be carried out when the belt conveyor line operation fund is invested:

1. Cover the main power switch of the belt conveyor line, check if there is any problem with the power supply of the belt conveyor line switch, and if the indicator light is on, and then proceed to the next step after checking if there is no problem.

2. Cover the main power switch of each circuit of the belt conveyor line and check whether there is any problem. Under normal conditions, the equipment does not pose, the belt conveyor line operation indicator is not lit, the frequency converter and other equipment indicators are lit, and the frequency converter display panel displays normally (no fault code indication).

3. According to the production process of the belt conveyor production line, turn on all electrical equipment in turn. After the first electrical equipment operates normally (motor or other equipment reaches normal speed and status), the next electrical equipment operates. During the operation of the belt conveyor line, it must be observed whether the size proportion and net weight of the conveyed goods meet the requirements of the belt conveyor line. Secondly, it should be noted that all kinds of workers should not touch the moving parts of the belt conveyor line, and laymen should not touch electrical components and control buttons at will. Finally, during the operation of the belt conveyor line, the frequency converter should not be short circuited. After specifying the necessity of maintenance, frequency conversion operation must be terminated, and professional technicians must be assigned for after-sales service.