What is the basis for the normal and stable operation of our automatic stacker

Collaborative mobile has fully played the role of many industries to improve the whole process. Packaging robots are generally used for light practical operations to put objects or services into small boxes or pallets. The software of the cooperative stacking robot system has a compact and streamlined design, which can provide the stacking of small precision and speed boxes, water bottles, packaging bags, trays and cartons from medium to large payloads to super heavy payloads.

In order to meet strict packaging standards, the palletizing robot provides an efficient and error free solution to adapt to harmful ergonomic regulations and repetitive work. They use lightweight cooperative mechanical arms to promote the lifting of goods, which is conducive to preventing workers from being injured.

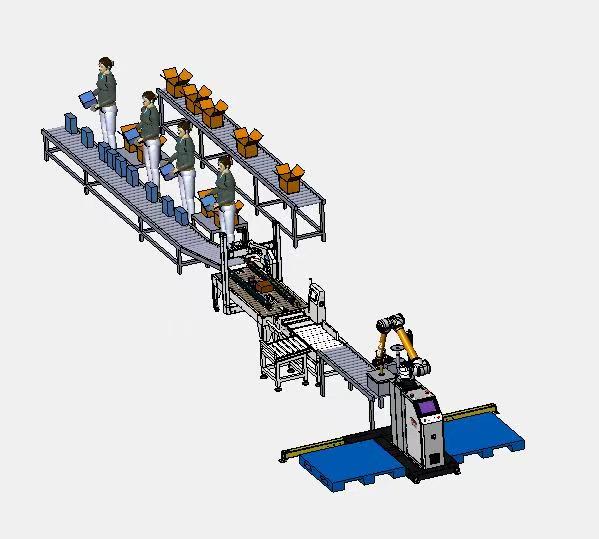

Cooperative mobile palletizing robot

Multifunctional

The cooperative mobile palletizing robot has many advantages, mainly including: it can be reconfigured and reprogrammed to meet a wide range of payload requirements. Due to its small size and light weight, once the work demand is reduced, the robot arm can be used as a new constellation.

Low maintenance costs

The components of the palletizing robot are equipped with low damage transmission devices. Due to its rugged and streamlined design, the cooperative mobile palletizing robot has a relatively long maintenance interval.

Power and speed

The packaging and stacking robot can improve the load with better efficiency, reduce the number of battery cycles, and improve the stacking rate of boxes, so as to achieve more dynamic performance.

Compact design

Their convenient size enables cooperative mobile palletizing robots to be quickly integrated into current system software to simplify performance and improve work efficiency.

Cooperative mobile palletizing robot provides many advantages for optimizing process, improving work efficiency and controlling cost. In essence, they are secure, easy to deploy and apply, and have great advantages, and can help to perform daily tasks that are likely to harm people's colleagues.