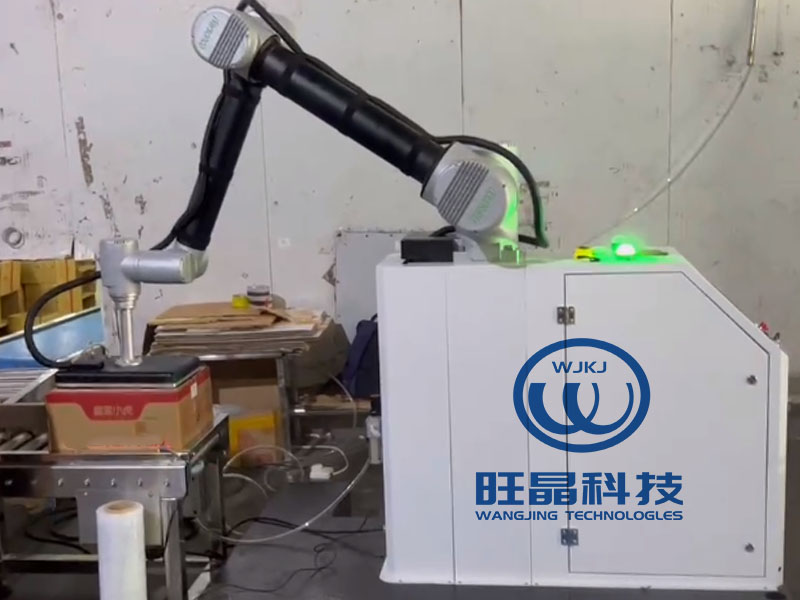

Through robot palletizing, workers can achieve accurate control of robot palletizer gripper

The gripper of cooperative palletizing robot, also known as end effector, clamp and mechanical gripper, is an important part of the palletizing robot. The design of robot intelligent gripper generally uses image system to identify the size of the workpiece, and servo motor to adjust the spacing of the clamping plates.

The whole gripper of the cooperative palletizing robot consists of a main frame, an air cylinder, two clamping plates and a servo motor. The clamping plate is used to clamp the workpiece. The utility model is characterized in that an image control system and a mechanism for adjusting the distance of a clamp are used. The image control system recognizes the workpiece size and controls the servo motor. The splint spacing adjustment mechanism is composed of air cylinder, two toothed transmission rods, two movable plates and gears. The gear is engaged with two toothed transmission rods, and the cylinder is connected with one of the movable plates. One end of the tooth shaped transmission rod is connected with the movable plate through a linear bearing, and the other end is fixed on the other movable plate, which is connected with two clamping plates.

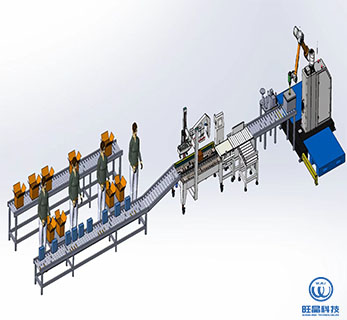

At present, the form and transportation of manual palletizing is not only characterized by high labor density, slow production pace, high cost, but also single function, which is only suitable for the palletizing of single or multiple materials. For the packaging materials of materials such as plates, top plates or stacking plates, fixtures need to be set for transportation or manual handling, which greatly increases the cost and operating costs. Therefore, the application of mechanical palletizing is more and more extensive. According to the shape, size, weight, material and operation requirements of the object to be grasped, there are a variety of structural forms, such as claw grasping, sucker grasping, simulated multi finger grasping, splint support grasping, etc. According to product packaging, such as carton, woven bag, barrel, bulk, weight, unit area, etc. It can also be divided into bottle claw, clamp claw, shutter claw, suction cup claw, bottle and stacking claw, clamp placing clapboard claw, grab claw, barrel claw, etc. The following is a brief introduction to the design elements of Haichuan palletizing robot:

1. The gripper design of the stacking robot needs to be considered from many aspects, such as the weight, size, material, etc. of the gripper target. Select different claws for different objects. For example, the plate-like workpiece can be vacuum adsorbed; The magnetic chuck can be used for magnetic media; PVC bag adopts clip type.

2. For the conveyor belt structure at the front end of the palletizing robot claw, the drum conveyor belt for bag grabbing generally has the national standard and requires the use of standard interfaces. For the belt of belt conveyor, how to realize it should be considered.

3. The economic working mode of the robot uses three power sources: electricity, gas and fluid. The structures involved and their manufacturing, use and maintenance costs are different. Electricity provided by the environment can reduce manufacturing costs.

4. The selection of palletizing robot model, the maximum load capacity and working radius of the robot, the inertia of the robot and the price of the robot, taking into account the design of the gripper.

5. The stacking robot grasps the weight, size and material of the target, and selects different claws for different objects, such as plates.

6. Whether the space layout of the moving end workpiece of the stacking robot and the gripper are suitable for the production environment.

7. The raw materials to be grabbed depend on the type of gripper, such as bagged raw materials are usually grabbed, boxed raw materials are pinched or vacuum suction grippers, furniture panels are usually suction grippers, etc.

The selection of palletizing robot gripper can generally be based on the production site environment, different working requirements and different design requirements for the gripper. The extensive use of Haichuan palletizing robot not only reduces the labor intensity, but also reduces the labor production cost, bringing many advantages for the rapid development of the company.