We believe that AI can help palletizing robots to complete high-risk tasks instead of humans

Stacking robot is a common automation equipment to improve the production efficiency of enterprises. In recent years, the aging problem of China's population is serious, and the development of manufacturing enterprises is faced with the problems of difficult recruitment and high cost of employment management. Therefore, more and more enterprises begin to turn their attention to robots, hoping to use industrial robots to solve the production problems of Chinese enterprises. It used to take more than ten people to complete the stacking work, but now only one stacking robot can complete it.

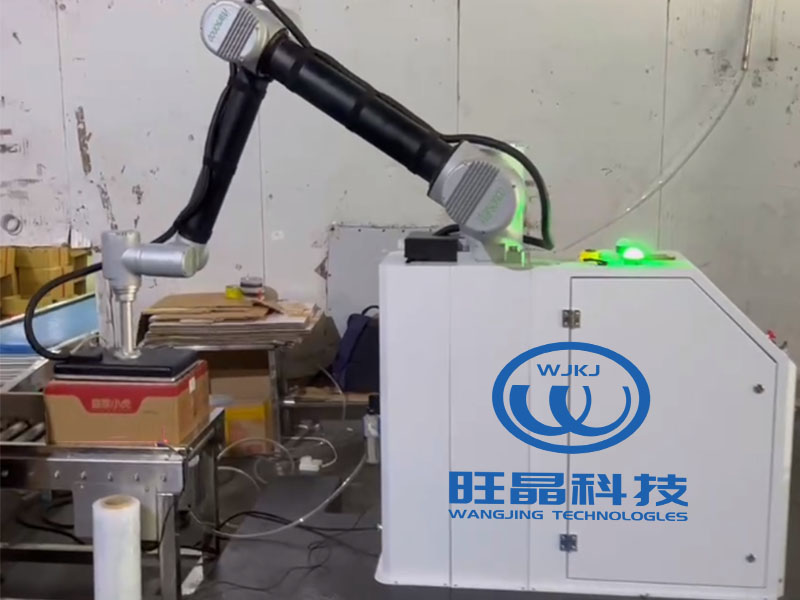

Mainly labor-intensive enterprises in manufacturing industry. With the shortage of labor force and the rise of labor cost, robot handling and palletizing production line has become the development trend of the future manufacturing industry. With the progress of science and technology and the acceleration of the modernization process, people have higher requirements for handling speed. The traditional manual palletizing can only be used when the material is light, the size and shape change greatly, and the throughput is small, which can not meet the needs of industrial production. Cooperative palletizing robot came into being. Robot stacker is the extension and expansion of workers' hands, feet and brain functions. It can replace people in dangerous, toxic, low temperature, high temperature and other harsh environments. It can help people to complete heavy, monotonous and repetitive work, improve labor productivity and ensure product quality. With the acceleration of China's social and economic development, the demand for medicine, food and other industries is expanding, and product packaging is changing from manual to mechanized, automatic and intelligent.

Due to the high labor intensity of manual stacking and the high turnover rate of employees, the production and management of the food and medicine industry are seriously affected, which is not conducive to the competition and development of enterprises. With the development of science and technology, the emergence of palletizing robots has saved time and manpower for product palletizing in pharmaceutical, food and other industries, helped enterprises complete transportation tasks more efficiently and quickly, reduced human errors and time, and brought more benefits to enterprises. With the development of the times, product stacking has changed from manual to mechanical automation and roboticization. More and more advanced stacking methods have solved the problem of labor shortage in China and promoted the development of China's machinery manufacturing industry. Highly automated and intelligent mechanical equipment will help all walks of life in China to achieve more efficient, safer and more convenient production, management and operation, and help the manufacturing industry develop better and better.

As long as the enterprise is good at observing and summarizing, grasping the development trend of the industry, and keeping pace with the times, it will have the opportunity to gain the advantages of industry development. Collaborative palletizing robot can replace human beings to complete high-risk and demanding transportation tasks, and help the industry develop more scientifically and stably.